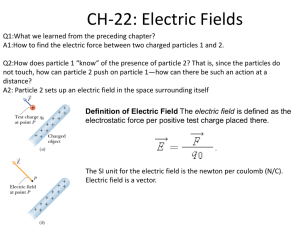

Tracer Particles and Seeding for PIV

Tracer Particles and Seeding for PIV

Seeding particles for PIV

Proper tracer must be small enough to follow

(trace) fluid motion and should not alter fluid or flow properties.

Proper tracer must be large enough to be visible by the camera.

Uniform seeding is critical to the success of obtaining velocity field. No seed particles, no data.

The seeding source must be placed cleverly so that the particles mix with the flow well.

Particles with finite inertia are known to disperse nonuniformly in a turbulent flow, preferential concentration

Seeding particles for PIV (cont’d)

The tracing ability and the dispersion characteristics depends on the aerodynamical characteristics of particles and the continuous medium;

The visibility depends on the scattering characteristics of particles.

The choice of optimal diameter for seeding particles is a compromise between two aspects.

Scattering characteristics of particles

Laser sheet leads to a low energy density – particle scattering efficiency is important;

Light scattering capability - scattering cross section C s is defined as the ratio of the total scattered power P s

, to the laser intensity I

0 incident on the particle

C

P s s

I

0

Example of scattering cross section (1)

The scattering cross section as a function of the particle size (refractive index m =1.6).

Example of scattering cross section (2)

Diameter d p

Molecule

1 m

10 m

Scattering cross section C s

10 -33 m 2

C s

(d p

/ ) 4

C s

( d p

/ ) 2

10 -12 m 2

10 -9 m 2

Scattering cross section as a function of the particle size

Mie scattering of small particle (1)

Light Scattering by an oil particle in air when refractive index m ~ 1.4. Left: 1

m diameter, right: 10

m diameter

Mie scattering of small particle (2)

Light scattering by a 1

m,

10

m, and 30

m glass particle in water.

Refractive index m = 1.52

Summary of particle light scattering for PIV

The ratio d p

/

I s90

/ I s0 decreases with increasing size parameter

, with values roughly in the range 10 -1 -10 -3 for scattering particles useful in PIV.

The resulting intensity of the scattered light for a given light sheet intensity will depend on the combined influences of C s and I s90

/ I s0

, which exhibit opposing tendencies with increasing particle size. In general, larger particles will still give stronger signals.

The ratio I s90

/ I s0 increases with increasing refractive index m . Hence particles in air gives stronger 90 o scattering than in water.

Tracking characteristics of particles

The tracking ability depends on

Particle shape – assumed spherical – aerodynamically equivalent diameter d p

Particle density

p

Fluid density

f and fluid dynamic viscosity

or kinematic viscosity

=

/

f

Newton’s Law governing the motion of a single particle:

p

d

6

3 p

d U dt p i

F i

General governing equation

p

d

3 p

6

d U p dt

3

d p

V

f

d

3 p

6

d U f dt

1

2

f

d

3 p

6 d V

dt

3

2 d p

2

(

f

)

1

2

t

t

0 d V

d

t d

Meaning of each term:

I.

Viscous drag according to the Stokes’ law

II.

Acceleration force

III. Force due to a pressure gradient in the vicinity of the particle

IV. Resistance of an inviscid fluid to the acceleration of the sphere (“added mass”)

V.

Basset history integral – resistance caused by the unsteadiness of the flow field.

Stokes’ drag law

The Stokes’ drag law is considered to apply when the particle Reynolds number Re p unity, where Re p is defined as is smaller than

f

Vd p

Vd p

Re p

In a typical PIV experiment with 10

m particles and 20 cm/s mean velocity,

Re p

=10x10 -6 x 0.2 / 1.46x10

-5 = 0.13 (air);

Re p

=10x10 -6 x 0.2/1.0x10

-6 = 2 (water).

Particle parameter

- the particle response time t p

Velocity lag of a particle in a continuously accelerating fluid:

2 if heavy particles (

p

>>

(

p

f

) dU f

V

U p

U f

d p

18

dt

The particle velocity response to the fluid velocity

f

) in a continuously accelerating flow is:

U p

( t )

U f

1

exp

t t p

Particle response time: t p

d

2 p

p

18

Particle parameter

- the Stokes number St

Stokes number St as the ratio of the particle response time to the Kolmogorov time scale:

St

t

/ p t k

St : the degree of coupling between the particle phase and the fluid.

St

0 the particles behave like tracers

St

the particles are completely unresponsive to the fluid flow.

Particle parameter

- the characteristic frequency C

In the case of gas flow where

p

>>

f

, characteristic frequency of the particle motion

C

18

p d p

2

Tracing ability in turbulence,

c

=2

f c u p

2 u f

2

( 1

1

c

/ C )

Figure of characteristic frequency

The response of particles in turbulence flow. (From Haetig J,

Introductory on particle behavior ISL/AGRAD workshop on laser anemometry (Institute Saint Louis) report R 117/76, 1976)

Particle size vs. Turbulence scale

Seeding particles need to be smaller than the smallest turbulence scale if one wants to identify all the structures in the vicinity of the flow. The smallest fluid length scale is called the Kolmogorov length scale, and it is related to the size of the smallest eddy.

Additional Considerations

Particle seeding uniformity

Additional Considerations (cont’d)

Secure sufficient spatial detail in the flow field a higher concentration of particles is generally needed with PIV than with LDV, with which it is possible to wait indefinitely for the arrival of a scattering particle in the probe volume.

A uniform particle size is desirable in order to avoid excessive intensity from larger particles and background noise, decreasing the accuracy, from small particles.

Particles that naturally exist in the flow seldom meet the above requirements. Hence, in PIV applications, it is often necessary to seed the flow with a chosen tracer particle. The particles are either premixed with the whole fluid (e.g., stirred ) or released in situ by a seeding source .

Imaging of small particles

Relation between real particles and particle image recorded in the camera can be analyzed by the diffraction limited imaging of a small particle

For a given aperture diameter D a and wavelength the Airy spot size

,

I ( x )

0

I max

d diff

2 .

44

f / D a

Imaging of small particles (cont’s)

With an imaging lens, the diffraction-limited size: d diff

2 .

44 f # ( M

1 )

Estimate of the particle image diameter: d t

( Md p

)

2 2 d diff d p

: original particle diameter

1 z

0

1

Z

0

1 f

M

z

Z

0

0

Seeding particles for PIV (liquid flow)

Type Material Mean diameter in

m

Solid

Polystyrene

Aluminum

10-100

2 - 7

Liquid

Gaseous

Glass spheres 10-100

Granules for synthetic coatings 10-500

Different oils

Oxygen bubbles

50 - 500

50-1000

Seeding particles for PIV (gas)

Type

Solid

Smoke

Liquid

Material

Polystyrene

Aluminum

Magnesium

Glass micro-balloons

Mean diameter in

m

0.5- 10

2 - 7

2 - 5

30-100

Granules for synthetic coatings 10-50

Dioctylphathalate 1-10

<1

Different oils 0.5 - 10

Commercial seeding particles - TSI

(http://www.tsi.com)

Silicon Carbide: Suitable for measurements in liquids and gases, silicon carbide particles have a narrow particle size distribution (mean diameter of 1.5

m ). Their high refractive index is useful for obtaining good signals in water, even in backscatter operation. They can also be used in high temperature flows. Supplied as a dry powder, they can be mixed in liquid to form a suspension before dispersing.

Titanium Dioxide: Titanium dioxide particles (mean diameter of 0.2

m ) are usually dispersed as a dry powder for gas flow measurement applications. The smaller particle size makes titanium dioxide attractive for high-speed flows.

It can also be used for high temperature flows.

Commercial seeding particles - TSI

( http://www.tsi.com

) (cont’d)

Polystyrene Latex : With an extremely narrow size distribution (nominal diameter of 1.0

m), polystyrene latex

(PSL) particles are useful in many different measurements.

Supplied in water, they are not recommended for high temperature applications.

Metallic coated: Metallic coated particles (mean diameter of 9.0

m ) are normally used to seed water flows for LDV measurements due to their lower density and higher reflectivity. They cannot be used where salt is present. Salt reacts with the metal coating, causing the particles to agglomerate and drop out of the flow.

Commercial seeding particles - TSI

( http://www.tsi.com

) (cont’d)

Particle

Type

Silicon carbide

Silicon dioxide

Nylon

PSL

Titanium dioxide

Metallic coated

Hollow glass spheres

Metallic coated,

Hollow glass spheres

Mean

Dia.

(µm)

Size

Range

(µm) Shape

1.5 Std. dev.= 1.4 Irregular

2.7 --- Irregular

4 Std. dev.= 1.5 Spherical

0.54 Std. dev.= 1.05 Spherical

3-5

9

---

4-12

Irregular

Spherical

8-12

10% < 3-5

90% < 14-17

Spherical

14

10% < 7

90% < 21

Spherical

Density

(g/cc)

3.2

2.3

1.14

1.05

4.2

2.6

1.05-1.15

Refractive

Index

(real)

Refractive

Index

(imag.)

2.65

1.47

1.53

1.55-1.6

2.6

0.21

---

---

---

---

---

2.62

1.5 ---

1.65 .21 2.62

Commercial seeding particles - Dantec

(http://www.dantecmt.com)

Polyamide seeding particles (PSP): These are produced by polymerisation processes and therefore have a round but not exactly spherical shape. They are microporous and strongly recommended for water flow applications.

Hollow glass spheres and silver-coated hollow glass spheres (HGS, S-

HGS): Intended primarily for liquid flow applications, these are borosilicate glass particles with a spherical shape and a smooth surface.

A thin silver coating further increases reflectivity.

Fluorescent polymer particles (FPP): These particles are based on melamine resin. Fluorescent dye (Rhodamine B:) is homogeneously distributed over the entire particle volume. In applications with a high background light level, fluorescent seeding particles can significantly improve the quality of vector maps from PIV and LDV measurements.

The receiving optics must be equipped with a filter cantered on the emission wavelength (excitation max.: 550 nm; emission max.: 590 nm).

Commercial seeding particles - Dantec

( http://www.dantecmt.com

) (cont’d)

PSP

Polyamide seeding particles

Mean particle size (µm)

Size distribution

Particle shape

5, 20, 50

1 - 10 µm

5 - 35 µm

30 - 70 µm non-spherical but round

Density (g/cm

3

)

Melting point (°C)

1.03

175

Refractive index

1.5

Material

Polyamide 12

HGS

Hollow glass spheres

10

2 - 20 µm spherical

1.1

740

1.52

S-HGS

Silver-coated hollow glass spheres

10

2 - 20 µm spherical

1.4

740

—

Borosilicate glass Borosilicate glass

FPP

Fluorescent polymer particles

10, 30, 75

1 - 20 µm

20 - 40 µm

50 - 100 µm spherical

1.5

250

1.68

Melamine resin based polymer

Particle generation

Liquid flow

Simple, select proper powder then mix w/ liquid

Gas flow

liquid droplets

Atomization or Condensation

solid particles

Atomization or Fluidization

Requirement for PIV

Nearly monodisperse size distribution

High production rate

Liquid droplets

Advantage

Steady production rate;

Inherently spherical shape;

Known refractive index

Problem

Form non-uniform liquid films on window

Generator

Laskin atomizer

Commercial atomizer (e.g., TSI)