超导磁体 - 国家同步辐射实验室

advertisement

Cryogenic System

WANG Li

Shanghai Institute of Applied Physics, CAS, China

The Eighth OCPA Accelerator School

July 27-Aug. 6, 2014, Xiuning, Anhui

2014-08-03

1

Contents

Introduction to cryogenic engineering

How to reach the low temperature

How to design a cryogenic system

Homework

References

2

Introduction to Cryogenic

Engineering

3

Introduction to Cryogenic Engineering

"Cryogenics the science and art of

producing cold"

Cryogenic Engineering

The design and development of systems and components which

produce, maintain, or utilize low temperatures.

Field of Cryogenics

Involving temperatures below 123K (-150oC) because the normal

boiling points of the so-called permanent gases, such as helium,

hydrogen, neon, nitrogen, oxygen, and air, lie below 123K.

根据在不同的低温温度区域、获得低温的方法及研究对象,又可把制

冷技术分为普冷技术和深冷技术。习惯上把普冷技术称为制冷技术,

把深冷技术称为低温技术。

4

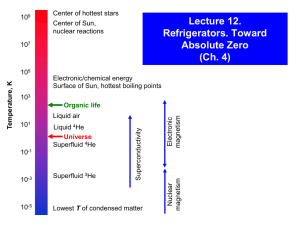

Temperature Scale (I)

10,000 K

Surface of sun

制冷

1,000 K

Water freezes

100 K

Cryogenics

Liquid oxygen (90.18K) Begins (123K)

Liquid argon (87.28K)

Air liquefies (78.8K)

Liquid nitrogen (77.36K)

Liquid neon (27.09K)

Helium

Liquid hydrogen (20.27K)

cycle

Liquid helium4 (4.21K)

refrigerator

Liquid helium3 (3.19K)

低温

10 K

1K

0.1 K

Magnetic

refrigerator

0.01 K

Dilution

refrigerator

0.001 K

极低温

5

104

102

100

10-2

Superfluid 3 He

10-4

10-6

Coldest temperature (bulk sample)

10-8

Bose-Einstein and Fermionic condensates

10-10

High T

ULT

Cryogenics

Temperature (K)

106

Plasma

108

Supernova explosions

Center of hottest stars

Fusion (hydrogen) bomb

Center of sun

Fission (atomic) bomb

Surface of hottest star

Surface of Sun

Room temperature

Metal boiling points

Organic life

Warmest superconductor (140 K)

Air liquefies

4He liquefies/Superfluid 4He

Space background (3 K)

Nuclear

reactions

1010

Conventional

refrigeration

Temperature Scale (II)

Coldest atomic temperature (sodium atoms)

Coldest nuclear temperature (rhodium nuclei)

Tempscale4 .cdr

6

Chronology of Cryogenic Engineering

~ 1850

1850

1877

1879

1879

1883

1892

1898

1895~1905

1908

1911

1907~1922

1926

1933

1934

1939

1940s

1942

1946

1946

1948

1952

Pre-cryogenics Era of Natural Ice

Artificial production of ice and the first air-cycle

refrigerator

Oxygen Liquefied

First frozen meat cargo from Australia to London

Domestic ammonia refrigerators

Liquefied nitrogen and oxygen

Dewar developed silvered vacuum vessel for

cryogen storage

Liquefied hydrogen

Industrial air liquefaction

Onnes liquefied helium

Discovered superconductivity

Cryogenic industries in the U.S.

Cryogenically propelled rockets

Magnetic cooling

First turbine expansion engine

First liquefied natural gas (LNG) plant

Ductile-brittle transformation

The V-2 weapon system was test-fired

Collins’ helium liquefier

Cryobiology (Discovery of cryoprotectants)

First 140 ton/day oxygen system built in

America.

Cryogenic Engineering Laboratory of U.S.

National Bureau of Standards (NBS)

1957

1958

1959

1959

1960

BCS theory of superconductivity

Multilayer cryogenic insulation (MLI)

72 in Liquid Hydrogen Bubble Chamber

Large NASA liquid-hydrogen plant at

Torrance, California, completed

Large-scale liquid-hydrogen plant completed

at West Palm Beach, Florida.

LNG tankers

1961

Type 2 Superconductors

1961

Space rocketry

1963

60 ton/day liquid-hydrogen plant completed

by Linde Co. at Sacramento, California

1966

Dilution refrigerator using He3-He4 mixture

1969

3250-hp dc superconducting motor

constructed for ship drive application

1970

Liquid oxygen plants with capacities

between 60,000 m3/h and 70,000 m3/h

developed

1971

Cryogenic wind tunnel

1983

Magnetic resonance imaging

1986

Ceramic superconductors

1960

2000 ~~~

7

Benefits of Low Temperatures

Cryogenics required for many quantum effects

– Superconductivity 超导(无电阻、完全抗磁性)

– Superfluids 超流(液氦II表现出几乎为0的流动阻力)

– Bose-Einstein condensates 玻色-爱因斯坦凝聚(原子在接近0K时特

殊物态)

Cryogenics is an enabling technology

– High magnetic fields (MRI, NMR, motors, accelerators)

– High precision and high speed measurements

– Low noise electronics and electromagnetics

– Liquefied fuels for high density

– Cryopreservation

– Cryosurgery

– Cryogrinding

– ……

8

Applications Involving Cryogenic Engineering

Cryobiology

Superconducting

Magnets & SRF

cavities

Space

Propulsion

MAGLEV

Trains

Cryosurgery

Elect. Power

Transmission

Air

Products

LNG & LH2

Automobiles

Liquefied

Natural

Gas

Steel

Manufacturing

LHe

Cryopumping

for

High Vacuum

Nuclear and

Particle

Physics

Cryogenic

Wind-tunnels

LH2

Cryomedical

MRI

Superconductivity

Research

Food

Processing

LOX

LAr

LN2

Material

Recycling

Cryocoolers

for Electronics

& SC device

CRYOGENICS

LNG

Elect.

Motors

9

Early Nobel Prizes

and Discoveries in Physics

Year

Red = Cryogenic phenomena

1900

Max Planck (1900)

Albert Einstein (1905)

Nobel Prizes

(begun in 1901)

Onnes (1908 Liquid helium)

1910

Onnes (1911 Superconductivity)

(1913) Properties of matter at low T

and production of liquid helium

Kamerlingh Onnes

(1918) Energy quantization

1920

(1921) Particle nature of light

Bose & Einstein (1924 condensate)

Louis de Broglie (1924)

Willem Keesom (1926 solid He-4)

Werner Heisenberg (1927)

S. Bose Einstein

(1929) Wave nature of particles

1930

William Giauque (1933)

P. Kapitza (1938 Superfluid He-4)

1940

Nobel Prize, 1978

(1932) Uncertainty principle

(1949) Thermochemistry and

Adiabatic demagnetization

10

Year

Recent Nobel Prizes in Physics

1970

1972

1973

Red = Cryogenic phenomena

Bardeen, Cooper, and Schrieffer

Esaki, Giaever, and Josephson

Theory of superconductivity

Tunneling in semi- & superconductors

1978

1980

Kapitza, et al.

Inventions & discoveries in low temp. physics

1985

1987

Klitzing

Quantized Hall effect

Bednorz and Muller

High-temperature supercond uctors

De Gennes

Ordering in matter (superco nd. & superfluids)

Lee, Osheroff, and Richardson

Ch u, Tannoudji, and Ph illips

Laughlin, Stormer, and Tsui

Superfluidity in He-3

Laser cooling and trapping of atoms

Fractional quantum Hall effect

Co rnell, Ketterl, and Wieman

Bose-Einstein condensation in dilute gases

Abrikosov, Ginzburg, and Leggett

Theory of superconductors a nd superfluids

Lauterbur and Mansfield

Magnetic reso nance imagin g (MRI)

1990

1996

NIST 1997

1998

2000

NIST 2001

2003

Medicine 2003

11

Cryogenic Applications and Operating Regions

10 6

低温超导

REFRIGERATION POWER (W)

Air liquefaction

小型制冷机

Accelerators

& Fusion

10

(Commercial)

10

10

10

10

Turbo-Brayton

1 GJ

Mid-size

(Special)

Cryopumps

SMES

GM+JT

FCL

Maglev

Magnetic

LTS

Electronics

He 5

JT

NbN

Elect.

10

GiffordMcMahon

FCL

Motors

Bearings

Wireless

1MJ

Micro-SMES

uency

q

e

r

f

Low

MRI

10

H2O cryotraps

Transformers

10

10

Mixed-gas JT

Stirling

Transmission

lines

Turbo-Brayton/Claude

1 TJ

Largesize

LNG

H2 ZBO

TE

IR

HTS

SQUIDs

H2

JT

50

TEMPERATURE (K)

Space

radiators

100

N2

JT

300

12

低温技术在粒子物理领域的应用

• 近十余年来,人类对物质结构的研究进入了大科学工程甚至超级

科学工程的时代,已建、在建并拟建大批的超导的加速器、对撞

机、探测器、核聚变装置、同步辐射光源和自由电子激光装置等

等。依靠这些超导科学研究装置,人类对物质结构的探索正期待

着重大突破。

• 低温技术( 2K-4K氦低温冷却技术)与超导技术(各类超导磁体、

超导射频腔等)的大规模应用是这些大科学工程的基本特征。现

代低温与超导技术随着这些大科学工程的研制迅速发展起来。

• 超导加速技术是实验物理技术,极其复杂的超导磁体和超导射频

腔,以及低温恒温器装置与以氦制冷机为核心的低温系统是其中

的关键设备。

13

欧洲CERN核子中心-强子对撞机(LHC)

•

1250个场强为8.3T的主二极(偏转)磁体,磁场强度梯度为223T/m的主四极(聚焦)磁体400个,分布

在周长为26.7km的加速器环上。

•

整个环等分为8个区域,每一区域内各个单元由一台制冷功率为18kW/4.5K的氦制冷机通过低温

传输线来冷却。

•

为达到8.3T场强,选用较为成熟的Nb-Ti合金作为超导线材后,基于NbTi合金特性,工作温度选

定为1.9 K,冷却介质是1.8-1.9K的超流氦(He II)。

ITER:国际热核聚变实验堆

• 超导托克马克装置

• 装置中心是高温氘氚等离子体环:15MA的等离子体电

流,核聚变反应功率达50万kW,每秒释放多达1000个

高能中子。

• 18个大型超导环向场线圈,将产生5.3T的环向强磁场。

线圈的作用是产生等离子体电流和控制等离子体位形。

• 系统罩于一个低温杜瓦中,坐落于底座上,构成实验堆

本体。

• ITER纵场导体和中心螺管导体采用Nb3Sn,其余导体采

用NbTi材料,超导磁体总重量约10130吨。

• 所有磁体采用4.5K超临界氦迫流冷却,低温制冷系统提

供55kW制冷量,80K的热辐射屏需要的冷量大约是

660kW。

• 大型氦低温技术和系统是保障ITER装置可靠工作的前提

和基础,用以支持其内部各种大中型超导磁体的运行。

15

未来的加速器及对撞机ILC:高能量和高亮度

•

直线对撞机(International Linear Collider-ILC):正负电子对撞机。采用低温超导加

速技术,由两台大型超导直线加速器组成,除了超导磁体,主加速器是一台由8000多个

9-cell超导加速腔组成的总长为 12km 的庞大机器,加速梯度高达31.5 MV/m, 可以把电

子束加速到250GeV的超高能量并进行对撞,质心系能量达到 500GeV,以后还可扩展到

1TeV。需建造约12个总冷量45kW/2K的超流氦制冷系统维持其运行。基本建设和加速器

设备的造价估算为67亿美元,需要2000名科研和工程技术人员持续工作5年以上。

16

高能轻子加速器:中微子工厂和介子对撞机

•

中微子工厂和介子对撞机 (Neutrino Factory & Muon Collider-NFMC):高能轻子加速

器。由于μ子的质量约比电子大200 倍,同步辐射损失小,容易在环形加速器中被加速到

更高能量。 NFMC是 ILC的竞争对手,更可能是它以后的高能加速器,两者具有互补性。

正在英国RAL建设的MICE实验装置,用于实验验证NFMCC中的关键技术之一-离子化冷

却μ介子技术,μ介子冷却通道采用超导螺线管磁体(18个)和液氢吸收器,以及低温

(液氢、液氦)冷却技术。

3.5 MW

Proton

Source

Hg-Jet Target

Decay

Channel

Buncher

Acceleration

Helical

Cooler

Pre Accel

-erator

Ring

Cooler

Collider

~ 4 km

Bunch

Merger

Li Lens

Cooler

17

美国能源部二十年大科学工程发展规划 (I)

美国能源部2003年11月公布的二

十年中长期大科学工程发展规划中

共有28项,拟投资数十亿美元。这

些大工程项目中的80%是以低温与

超导技术为工程基础。

“这些大科学工程将使科学发生革

命,使美国科学位于世界前沿,将

会产生重大科学发现,对人类社会

做出重大贡献”

-Spencer Abraham

(美国前能源部长)

18

美国能源部二十年大科学工程发展规划 (II)

19

19

国际拟建大科学装置中的低温与超导技术

• 未来的国际正负电子线性直线加速器ILC计划采用近万个9壳1.3GHz纯铌超导

腔,需建造12个总冷量45kW/2K的超流氦制冷系统维持其运行;

• 美国散裂中子源装置SNS拟采用81个805MHz的纯铌超导腔和总冷量

2.4kW/2.1K的制冷系统;

• 欧洲CERN拟建的高强度质子直线加速器SPL将采用178个704MHz的纯铌超导

腔和总冷量4.5kW/2K的制冷系统;

• 德国GSI实验室在建的研究反质子和离子的实验装置FAIR全部采用超导磁体,

需要总冷量30-40kW/4.4K的制冷系统;

• 德国DESY实验室拟建的欧洲X ray-FEL装置将采用928个1.3GHz纯铌超导腔,

仅直线加速部分即需要2.45kW/2K的超流氦制冷系统;

• 美国康奈尔大学建造的能量回收型加速器ERL需要390个7壳1.3GHz纯铌超导

腔和约10 kW/2K的制冷系统;

• 英国建在德拉斯珀瑞的G4LS-ERL/FEL装置需要102个1.3GHz纯铌超导腔和约

3.5kW/1.8K的超流氦制冷系统。

• FRIB, LCLSII, ERL, ……

20

中国的国家级大科学工程装置

SRF-B

SRF-A

上海第三代同步辐射光源装置

BESIII

SCQ-A

SCQ-B

北京正负电子对撞机

重大改造工程

21

北京正负电子对撞机重大改造工程

BEPCII低温设备

新增三类超导设备:

一对撞区聚焦磁体(SCQ)

一对高频加速腔(SRF)

一个探测器磁体(SSM)

一套氦低温系统:

2套500W/4.5K氦制冷机系

统

三种冷却方式

(哈工大设计制图)

22

22

SSRF超导设备和低温系统

正在运行:

• 3套500MHz Single-cell超

导射频腔,液氦浸泡式冷却

• 一套氦低温系统:

650W/4.5K氦制冷机系统

拟建:

• 1套超导3次谐波腔+1套

SCW,液氦浸泡式冷却

• 一套氦低温系统:

650W/4.5K+100W/2.0 K

氦制冷机系统

23

加速器和光源装置中的超导设备及低温技术

冷却对象

功能

超导射频腔(SC

Resonance

加速电子

Frequency CavitySRF cavity)

低温永磁波荡器

(Cryogenic

Permanent Magnet

Undulator-CPMU)

超导插入件(SC

Undulator-SCU, SC

Wiggler-SCW)

产生同步辐

射光

磁体材料

工作温区

冷量范围

冷却方式

冷却技术或冷源

纯铌腔体

4.5K or

1.8K~2K

~几百瓦

液氦浸泡式

大型氦制冷技术

Liquefier+LHe fill-in

永磁体

NdFeB、

PrFeB

50K-150K

~几百瓦

对流+热传

导

LN2 or GN2对流冷却,或者

小型低温制冷机传导冷却

超导材料

NbTi/Cu、

Nb3Sn/Cu

超导磁体(四极铁、

超导材料

聚焦、偏转

二级铁、弯铁、六

NbTi/Cu、

等

极铁等)

Nb3Sn/Cu

4.5K

2K~4.5K

几瓦~几十

瓦(取决

于动态负

载量级)

大型氦制冷技术

液氦浸泡式; Liquefier+LHe fill-in or

对流+热传 小型低温制冷机技术

导;热传导 Cryocooler+LHe fill-in

by thermo-syphon or by

GHe-recondensening;

Cryocooler by conduction

液氦浸泡式;

对流+热传 大型氦制冷技术 or 小型低

几瓦~百瓦

导等

温制冷机技术

24

气体储罐、纯化系统等

液氦杜瓦、低温阀箱、低温传输管线、过冷

换热器、气液分离器、测量控制系统等

How to reach the LT?

低温恒温器等

25

How to reach the

low temperature?

26

Approach to obtain the low temperature

Approach to obtain the low temperature (>1K)

节流; 绝热膨胀; 绝热放气制冷;减压降温;相变制冷(液体气化制冷、

固体升华制冷);He3-He4稀释制冷;绝热退磁制冷;涡流制冷;热电制冷;

吸附制冷 ……

Refrigeration and Liquefaction cycle

Two adiabatic expansion processes:

Isenthalpic expansion Throttle valve

Isentropic expansion Turbine and piston engines

Cycles: Linde-Hampson, Brayton,Claude, Kapitza, Heylandt, Collins, etc.

Cryocoolers or Cryocoolers+JT

G-M coolers (Simon expansion)

Pulse tube coolers

Stirling coolers

……

27

Refrigeration and Liquefaction Cycle

Simple refrigerator

Simple liquefier

• To reject heat at high temperature

• To reject heat at high temperature

• To absorb heat at low temperature

• To produce liquid at low temperature

Power

Power

P > 0

T

Heat

Load (TL)

P > 0

T

P1

Gas

supply

Q

Q

Q

Cold sink

(TH)

P < 0

T

P < 0

T

Liquid

vessel

P1

P2

dT=0

T1

T

dP=0

T2

ds=0

P2

Power

Power

P2

Cold

sink (TH)

P1

dT=0

T

ds=0

dP=0

T’2

28

s

s

Refrigeration vs Liquefaction Cycle

Refrigeration

Liquefaction

Closed loop system

Open loop system

• Operate as a closed loop, constantly

circulating the same working fluid.

• Liquid product is removed at cold end

and equivalent the make-up gas added at

warm end.

• No accumulation or withdrawal of fluid in a

refrigerator.

Balanced refrigerant flow

Unbalanced refrigerant flow

• Mass flow rate of the refrigerant is the

same at all points of the cycle.

• Mass flow rate of return stream is

smaller than that of stream being cooled

by just the amount of liquid removed.

Absorb heat at low temperature

Refrigerant production

• Fluid coolant evaporates constantly at low

temperature end and returns to complete

cycle.

• Cold liquid is produced but the

countercurrent refrigerant effect of the

product withdrawn has been lost.

Joule-Thomson isenthalpic expansion

The J-T process is isenthalpic,

dh 0

The isenthalpic, or J-T, expansion coefficient

JT

T

P h

For a perfect gas,

JT

1

cP

v

T T v

P

Pv RT

R

v

v

P T

T P

Conclusions

h

•

A perfect gas would not experience any

temperature change upon expansion

through an expansion valve.

•

The more imperfect the gas, the better.

•

A liquid is the most imperfect gas as

known.

•

To achieve the liquid state before the JT expansion.

•

Among liquids, the most non-ideal ones

are the highly polar fluids

•

Ammonia, solfur dioxide, and

fluorocarbons (R series refrigerants)

Therefore, for a perfect gas

JT

1

cP

v

T T v 0

P2, T2, h

P1, T1, h

dh 0

30

The J-T Cycle

Refrigerator

Liquefier

31

Conclusions

•

•

The inversion curves

Maximum inversion temperature below ambient temperature: Neon, hydrogen,

helium.

For these gases, a system can not use the Joule-Thomson effect alone in

producing low temperatures, and other methods, such as expansion engines or

precooling, must be used.

Fig. Isenthalpic expansion of a real gas

32

Isentropic expansion

For an isentropic expansion,

ds 0

The isentropic expansion coefficient,

T T v

S

P S cP T P

P1, T1,

h1, s

S

S 0

if the volumetric coefficient of expansion,

W

dP 0, dT 0

v

0

T P

P2, T2,

h2, s

This is the case for all fluid (Water between 0oC~4oC is one

exception).

For an ideal gas,

Pv RT

v / T P R / P v / T

S v / cP

33

The Brayton Cycle

Refrigerator

Liquefier

34

h

Compare

h

1

h S

cP

and

and

S

S

v

1

T

v

T P

cP

v

v 1

1 v

v

v T

T

T

T P c P T P

T P c P

v

RT

h S

cP

PcP

h S

•

•

•

•

•

when

v0

cP

At low temperature and high pressure, v 0 , so, use J-T expansion at low T and high P.

Near critical point all fluids, c , which is exactly the condition desired for J-T

P

expansion.

Therefore, when the expansion is for producing liquid or occurs near or below the critical

point, J-T expansion may be indistinguishable thermodynamically from isentropic

expansion.

Real expansion engine have difficulty operating in two-phase region, may be only about

85% of isentropic.

Hardware reasons to prefer valves to engines.

35

Examples

36

Modified Claude system with LN2 precooling

T1

T2

ORS

Recycle

compr.

GHe

buffer

GHe

LHe

LN2

Drier

LHe storage

dewar

Air

T1

T2

ORS

Recycle

compr.

GHe

buffer

GHe

LN2

LHe

Drier

Air

LHe storage

dewar

Qc

Qc

37

System performance parameters

COPreal

FOMR

COPideal

卡诺比/卡诺效率/制冷机效率:循

环热力过程完善度

Figure of Merit or Percent Carnot

QTC

heat _ absorbed@TC

COP

compressio

n _ work

Wcomp

y

m f

m comp

Wcomp

制冷系数:制冷循环热效率

Coefficient of Performance

m f

Wcomp

mass_ liquefied

mass_ compressed

液化率

m comp

compression _ work

mass_ liquefied

compression _ work

mass_ compressed

38

Thermodynamically ideal systems

Ideal refrigeration system with isothermal-sources:Carnot refrigerator

TH

TH

2

1

QH

T

Wnet

TC

3

QC

4

QC

C-R

TC

s

12: Isothermal reversible compression, reject QH;

23: Isentropic (adiabatic, reversible) expansion, THTC;

34: Isothermal reversible expansion, absorb QC;

41: Isentropic compression, TCTH .

The COP of Carnot refrigeration

system is independent of the

refrigerant and is limited by TH and

TC only.

Q

W

Q

C

H

net 0

COPideal

TC s

Q

Q

m

TC

C

C

Q

TH s m

TC s TH TC

m

W net

Q

H

C

39

,For

300

TH = 300K, COPideal

3

1 10

100

10

1

C OP

i

0.1

4

3.0110

0.01

3

1 10

10 4

1

5 5

3.32210

1 10

0

0.01

100

T

200

i

300

300

5

1 10

4

1 10

3

1 10

1

100

C OP

i

10

1

0.1

3.33310

3

0.01

3

1 10

0

0.01

100

T

200

i

300

300

40

,

Ideal liquefaction system with isentropic expansion

Analysis: CV: {COMP+EXPAN+LD}

m

f

m

y 1

P2

P1

dT=0

T

W

m

f hf m

hH m

f (hf hH )

Q

H

net

Wideal

Q H

(h f hH )

(h f hH ) TH (s1 s2 ) (h f hH ) TH (s f sH ) 0

f

f

m

m

ds=0

dP=0

s

41

Examples

42

气体储罐、纯化系统等

液氦杜瓦、低温阀箱、低温传输管线、过冷

换热器、气液分离器、测量控制系统等

低温恒温器等

How to design a cryogenic system?

43

How to design a

cryogenic system?

44

How to design a cryogenic system?

Tasks and components of cryogenic system

低温系统的主要功能及主要组成

Cooling Cycles 冷却循环方式

Overall design 总体设计

Cooling capacity vs heat load/leakage 制冷量和热负载(漏热)确定

Cooling schemes 冷却方式选择

Operation modes 运行工况(或模式)优化

Machine components 主要设备的确定

Cryogen properties and Material properties

低温工质物性和材料低温性质

2K Cryo-system

45

He

Gas

Tank

A Typical Cryogenic System

Including:

Compressors

Cold Box

HEXs

Thermodynamics/Heat-transfer/Fluid-mechanics/Fluid-Material-properties/Numerical-simulation

Project Budget: Heat load vs. Refrigeration (Static & dynamic heat loads)

Cooling sources: Working-medium vs. Refrigerator or Cryocooler vs. Cryogens

Cooling method: Bath vs. 2Φ vs. Supercritical vs. Subcooled vs. LHe II

Refrigerator plant: Compressors/Heat-exchangers/Expanders/J-T valve/Liquid-dewars/cold-comp. /Absorbers/etc.

Equipment: Gas-tanks/Purifiers/Filters/Transfer-lines/Valves/Pumps/Instrument-air/cooling-water/etc.

Instruments: Temperature/Pressure/Flow-rate/Liquid-level/Fluid-quality/etc.

Cryo-operation: Capital bill for Auto-control vs. Labor & materials costs vs. Down-time-loss/etc.

Vacuum chamber@ 300K

Turbin expanders

Free-Molecular

Heat Transfer

JT valves

Heat Flux

Vacuum

Cryogen Dewar

Cooling Tube

Radiation

LN2

Cryo-Valve Box

Cold Mass @ 4.5K

2Φ Helium

ΔP, ΔT, Δρ, Δχ,

M*Cp*ΔT

Convection

MLI

Conduction

ΔP, ΔT, Δρ, Δχ,

Cooling of Permanent current leads:

LN2 Shield @ 80K •Conduction-cooled

Vacuum

Pump

MLI

Conduction

CRYOSTAT

•Ghe-cooled

Permanent current leads:

•Cu leads

•Binary leads: Cu leads + HTS leads

46

Basic Knowledge

Thermodynamics 工程热力学

• Refrigeration/Cooling capacity Cold mass thermal capacity

Heat taken away from the cold mass, i.e. cooling down

• Refrigeration static heat load

Heat transferred from outside worlds, i.e. keeping cold

• Refrigeration dynamic heat load

Heat added to target, i.e. beam-based heating, RF heating, AC losses, etc.

•

•

•

•

Heat transfer 传热学

Thermal calculations for vacuum-insulation;

Thermal conduction in solid supports and links in mechanical systems;

Heat convection between gas, liquid, and solid in cooling systems.

Boiling and condensing

Fluid mechanics 流体力学

• Single- and two-phase fluid flow calculations;

• Safety device sizing and verifications.

Material properties 制冷工质和材料低温物性

• Cryogen properties;

• Mechanical material properties.

Numerical simulation 有限元或有限差分数值模拟

• Commercial computational software, i.e. Fluent, Ansys, Aspen Plus……

47

Tasks and Components of Cryogenic System (I)

• Production of refrigeration power or cryogen -冷源:提供冷量或者低温工质

Refrigerator/liquefier (recycle compressor, ORS, cold box) or cryocoolers– 制冷机或液化机、小型制

冷机(GM, PTR, or cryocooler + JT, etc.)等

• Distribution of cryogen – 低温工质的贮存、分配和输送

V-L separator & cryogenic valve boxes & transfer-lines –气液分离器、低温阀箱和传输管线等

• Cooling of components – 热负载的冷却

Cooling circuit (sub-cooler, cold pump, recondenser, cooling pipes, etc.) –冷却回路(过冷器,冷泵,

再冷凝器等); Cold mass (SC device, test samples) –冷质量;Cryostat (including supports,

thermal insulation, thermal shields, vacuum vessel, current leads, quench protection, etc.) – 低温恒

温器

• Process control and monitoring – 低温系统的监控

Cryogenic instrumentation and control system – 低温监控系统(温度、压力、流量、液位、电压等测控

元件,PLC模块等)

48

Tasks and Components of Cryogenic System (II)

• Variability and flexibility of refrigeration to handle different modes of

operation – 不同运行模式下冷量的调节

• Cryogen recovery and storage as liquid or gas – 低温工质的回收和储存

Cryogen recovery and storage systems (gas collection headers, dewar, tank, recovery

compressor)- 杜瓦、气罐、回收压机等

• Cryogen purification - 低温工质的纯化

Cryogen purification system (filters, absorbers, driers, gas analyzers, internal or external

purifiers) – 过滤器、吸附器、干燥器、气体分析仪、内/外纯化器等

• Handling of safety aspects – 低温安全

Safety device (pressure relieve valves, burst-disc, Oxygen monitor, etc.)

• Accommodation to cryogenic system – 低温系统的布局

• Others (instrument air system, cooling-water system, vacuum system, etc. )- 仪表

空气系统、冷却水系统、真空系统等

49

Cooling Cycles

Cooling Cycle to be Chosen:Closed- or Open-cycle

冷却循环方式:开式或闭式

Refrigeration loads 制冷量

Operating temperature range 运行温度范围

Operating period 运行时间

Convenience of operation 操作简便性

Cost 成本(capital cost & operation cost 设备和运行)

Stability and reliability etc. 运行可靠性、稳定性等

50

Overall Design

Study refrigeration loads (冷量的确定)

Choose cooling principle/scheme (冷却方式的选取)

Operating modes(运行工况/模式)

Choose machine components (主要设备的确定)

51

冷却对象(冷质量):超导设备及工作温度

超导加速器设备类型

超导磁体

通过大电流产生强磁场,实现高能粒子的聚焦、偏转、旋转、摇摆、散射。

超导二极、四极、六极、超导螺旋管、超导弯铁、超导插入件(Wiggler,

Undulator)、超导异型磁体等等.

超导射频腔

通过高频功率源加载产生交变强电场,加速带电粒子。

单壳、多壳,低频至高频(MHz-GHz).

功率输入器

电流引线、功率耦合器或波导管等。

超导体的工作温度条件

低温超导磁体和超导射频腔:1.8K(超流氦)-4.5K

电流引线: 4.2K-300K,高温超导电流引线:30K-77K

功率耦合器或波导管:1.8K-300K

52

Cooling capacity vs Heat-load 制冷量和热负载(漏热)

― How big the

refrigerator/liquefier

/cryocooler has to be?

制冷系统的规模

300K 真空容器

辐

射

漏

热

功

率

输

入

器

漏

热

Static heat 静态漏热

•Radiation heat 辐射漏热

•Conduction heat 导热漏热

•Free-molecular heat

transfer 剩余气体传热

动

态

漏

热

支

撑

导

热

漏

热

各

种

管

线

漏

热

测

量

引

线

漏

热

低

温

阀

门

漏

热

中间温区冷屏(液氮冷屏)

辐

射

漏

热

功

率

输

入

器

漏

热

支

撑

导

热

漏

热

各

种

管

线

漏

热

测

量

引

线

漏

热

液氦温区冷质量

LN2

低

温

阀

门

漏

热

超

导

线

接

头

漏

热

LHe

53

超导腔和超导插入件低温冷却系统的热负载

•

低温系统的热负载主要包括:超导腔热负载、超导插入件热负载和超导设备与制冷机之

间低温工质的传输与控制设备的热负载三部分。

•

超导设备的热负载又分为静态热负载和动态热负载;传输设备的热负载含低温传输管线、

各类阀箱、制冷剂储存杜瓦等设备的热负载。

•

超导设备静态热负载是指在超导体低温恒温器中的低温设备与室温之间由于热辐射、热

传导等而产生的固定热量传递。通常,会在超导设备恒温器中采取多种措施以将低温下

热负载减小到最低程度,如在液氦容器与室温间通过中间温度冷屏(如液氮冷屏、20K

冷屏)及高真空进行热隔离,在低温超导设备与室温束流管道间设置波纹管及中间温度

热隔离段等。

•

超导高频腔的动态热负载一部份来源于高频功率在超导腔壁的残留电阻上产生的热损耗,

另一部份来源于高频功率在耦合器上产生的热损耗。其中前一部份与超导腔的性能和运

行参数直接相关。

•

超导插入件的动态热负载则主要来源于束流辐射等。

54

Cooling principle/scheme 冷却方式的选取

Mainly to be determined by 主要取决于:

•Temperature range of operation 运行温度要求 (温度/压力稳定性、温度均匀性等)

•Cooling efficiency 冷却效率

•Geometry of cold mass 冷质量的形状及结构

•Heat loads (static and dynamic) 漏热

•Cryogen flow conditions (single or two-phase) 低温工质流体状态(单相或两相流)

•Heat exchange and heat transport conditions (precooling, recooling, …) 热交换或传热状况

•Allowed pressure levels (magnets, cavities, etc.) 允许的工质压力范围-压力容器及管道要求

•Spatial distribution of the cold components (locations of magnets, cavities, coldboxes, cryostats,

dewars). 冷组件的空间分布及空间可利用率

Mainly Including 主要包括:

•

Bath cooling or Pool boiling

浸泡式冷却

•

Forced flow cooling

迫流冷却

•

Conductive cooling

热传导冷却

•

Thermal-siphon cooling

热虹吸冷却

55

Bath cooling or Pool boiling

Direct cooling using liquid cryogen storage or closed-cycle refrigerator. The cold

mass is immersed in the cryogen pool (saturated, subcooled, superfluid)

•

Most efficient cooling mode good

•

Solid and Leak-tight cryogen vessel to contain the cold mass technical

difficult for large size or complex geometry

•

Electrical insulation and mechanical strength hard

•

High vapor pressure when quenched safety issue

•

Long time recovery after quench cost

Liquid Helium I

Superfluid Helium II

56

Liquid Helium I

Saturated He I at about atmospheric pressure (1.013-1.25 bara) with a temperature of

4.2~4.5 K is used for bath cooling. Heat flux of 20 J/g/s of helium flow is absorbed by

the latent heat of helium. The helium is boiling at constant temperature, defined by the

equilibrium vapor pressure in the cooling loop.

Lhe consumption rate: 1 L/hr ( 0.033 g/s)=0.7 W Heat load

Cooling power: 1 W=1.4~1.5 L/hr (0.05 g/s)

Superfluid Helium II

Saturated He II at about sub-atmospheric pressure (16-31 mbar) with a temperature of

1.8~2.0 K is used for bath cooling. Heat flux of 22~23 J/g/s of helium flow is absorbed

by the latent heat of helium II. The heat flux is conduction-transferred at 0.6~0.7

W/cm^2 in helium II at constant temperature, defined by the equilibrium vapor

pressure in the cooling loop.

Lhe consumption rate: 1 L/hr ( 0.041 g/s)=0. 91 W Heat load

Cooling power: 1 W= 1.1 L/hr (0.0451g/s)

57

Forced flow cooling

Indirect cooling. Cryogen flows through metal tubes that attached onto

the cold mass.

•

Very efficient cooling mode good

•

Simple structure good

•

Cooling of the SC conductor joints need special care

•

Electrical insulation complicated

•

Cryogen flow control sophisticated

•

Low vapor pressure when quenched less safety issue

•

Quick recovery after quench

BEPCII SCQ magnet

58

He cooling loop

N2 cooling loop

Two-phase Helium

Two-phase helium is used as the forced flow in piping that is attached onto the cold

mass. Same as the saturated liquid, the helium flow at 1.0 g/s may absorb 20 J heat flux

by its latent heat. The helium boils at constant temperature, and its fluid quality

increases along the cooling path. The temperature is defined by the equilibrium vapor

pressure in the cooling loop that is normally established by the suction pressure of the

helium compressor. High heat transfer rate may be obtained at small temperature

difference up to 1 W/cm^2 in the nucleate boiling region.

Lhe consumption rate: 1L/hr=0.7 W Heat load

Cooling power: 1 W=1.4~1.5 L/hr

Subcooled single-phase Helium

Below critical pressure of 2.3 bar, heat is absorbed by the sensible heat of the helium with

a corresponding increase in temperature, 0.7 J/(g/s-K) at T=0.1K. This is a factor of 30

less than in the two-phase cooling at the same helium mass flow rate. Higher mass flow

rates lower the temperature rise. Normally, the maximum allowed temperature rise is

about 0.1 to 0.2 K and limits maximum length of component to be cooled in series.

Because in subcooled helium, vapor bubbles can not occur, the flow instabilities such as

59

in two-phase flow conditions are excluded.

Supercritical Helium

Above critical pressure of 2.3 bar, heat is absorbed by the sensible heat of the helium with

a corresponding increase in temperature, 0.5 J/(g/s-K) at T=0.1K. Higher mass flow rates

lower the temperature rise. Normally, the maximum allowed temperature rise is about 0.1

to 0.2 K and limits maximum length of component to be cooled in series. Because in

supercritical helium, vapor bubbles can not occur, the flow instabilities such as in twophase flow conditions are excluded.

Conductive cooling

Indirect cooling based on heat conduction. Completed dry cooling.

•

Simplest in fluid flow and pressure control good

•

Cooling capability and efficiency big concerns

•

Small stability margin only for low loss magnets operating in a pure steadystate regime

T

Qc (T ) A

L

60

小型低温制冷机冷却系统

Conduction-cooled

Thermosyphon-cooled

61

小型低温制冷机的选型

目前,常用的小型制冷机主要有GM型制冷机和脉冲管(Pulse Tube)型制冷机,其

性能比较如下表所示。

脉管制冷机(PT-415)

G-M制冷机(RDK-415D or KDE415)

单机最大冷量范围

40W﹫45K,1.5W﹫4.2K

35W﹫50K,1.5W﹫4.2K

维护周期

低温部件无需 维护,其余部件周期

25000小时

整机需要维护,周期10000小时

运行方位

垂直安装运行,最大偏离角为10o

可任意方位安装,冷量有损,最大15%损

失量

磁场影响

低温蓄冷器处磁场小于1.5T,其它低

温部件对磁场无要求,也不会影响磁

场分布,旋转阀电机处磁场应小于

0.04T

低温蓄冷器处磁场小于1.5T,低温部件处

磁场小于0.5T,旋转阀电机处磁场应小于

0.04T

振动

在冷头轴向方向有4-7μm量级的振动,

在冷头横向方向有2μm量级的振动;

采取减振措施,冷头轴向方向振动可

至<<1μm。

在冷头轴向方向有20μm-30μm-量级的振

动,在冷头横向方向有10μm量级的振动。

采取减振措施,冷头轴向方向振动可至

1~5μm量级。

厂商

Cryomech, USA

日本住友,或南京柯德

62

Cryomech/USA coolers

Valve Motor

Ballast Tank

Rotary Valve

1st Stage Cold Head

2nd Stage Cold Head

Cooler Top Plate

Æø¿â

ÀäÈ´Æ÷

Àä¶Ë»»ÈÈÆ÷

Èȶ˻»ÈÈÆ÷

ѹËõ»ú

x

С¿×·§

ÐîÀäÆ÷

1.5W/4.2K PTR-415 PTR cryocooler Produced by Cryomech/USA

Âö³å¹Ü

63

Sumimoto/Japan coolers

1

2

7

8

1.5W/4.2K SRDK-415D GM cryocooler

Produced by Sumimoto/Japan

3

4

5

6

64

Conduction-cooled SCU

Cryostat for SC magnet with indirect cooling

Conduction-cooled current leads

Horizontal bath cryostat for a wiggler magnet

65

Thermo-syphon cooling

Gravity (density difference)-driven flow.

SC magnet He fill/vent turret

LHe vessel

Cryocoolers 4K/60K

Current lead

assemblies

LHe piping

1

He

fill

pipe

2

20 K radiation shield

LHe vessel

HTS leads

He

recondenser

60 K radiation shield

Cryostat vacuum vessel

Cold mass support

Beam chamber

Beam chamber

thermal link to

cryocooler

20K radiation shield

60K radiation shield

Beam chamber

@ 20K

LHe

Heater

RF fingers

SC coils

Cryocoolers 20K/60K

3

4

66

Operation modes 运行工况/模式

Cool down

Normal operation

Warm up

Failure modes

•

Quench

•

Vacuum failure

•

Electricity failure

•

Cryogen leakage

•

……

67

Cryogen Properties 低温工质物性

常用低温工质的基本性质

氧 O2

氦 4He

氦 3He

(n)–正常氢

(e)–平衡氢

氮 N2

空气

32.00

4.003

3.016

2.016

28.018

28.966

K

90.188

4.224

3.191

20.39(n)

20.28(e)

77.36

78.9/81.7

Tm

K

54.4

—

—

13.96

63.2

—

临界温度

Tcr

K

154.78

5.2014

3.324

33.24(n)

32.90(e)

126.26

132.55

临界压力

Pcr

MPa

5.107

0.2275

0.1165

1.297(n)

1.287(e)

3.398

3.769

三相点温度

Ttr

K

54.361

—

—

13.95(n)

13.81(e)

63.15

—

三相点压力

Ptr

kPa

0.152

—

—

7.2006(n)

7.0406(e)

12.536

—

饱和液体密度

ρL

kg/m3

1142

125

60

≈70.8

808

≈873

饱和蒸气密度

ρV

kg/m3

4.8

≈15.5

≈22

1.34

4.61

4.48

密度(标准状态)

ρ0

kg/m3

1.4289

0.1785

0.1345

0.0899

1.2506

1.2928

气化热(1atm)

rV

kJ/kg

212.76

20.8

8.5

447

199

205.5

熔化热(近似)

rm

kJ/kg

13.95

5.7

—

58.7

25.8

项 目

符号

分子量

M

沸点

Tb

熔点(近似)

单位

68 —

Properties of He

T [K]

P=3 atm

P=100 atm

P=2 atm

I: L-V two-phase

P=1 atm

IV

V

II: Near critical point

P=0.5 atm

III: Subcooled LHe

II

5.2 K

IV: Supercritical

III

I

V: GHe

S [kJ/kg-K]

c =69.6 [kg/m3]

Critical point

Tc =5.201 [K] Pc =2.275 [bar]

Normal boil point

Lower lambda point

Tnbp =4.224 [K] Pnbp =1.013 [bar] nbp_L =124.96 [kg/m3] nbp_V =16.89

[kg/m3]

Tλ_Lower =2.177 [K]

Pλ_Lower =50.36 [mbar] λ_liq =146.21 [kg/m3]

Upper lambda point

Tλ_upper =1.763 [K]

Pλ_upper =30.13 [bar] λ_liq =180.39 [kg/m3]

69

4He相图

Critical

point

Tc =5.201 [K]

Pc =2.275 [bar]

Normal

boil point

Tnbp =4.224 [K]

Pnbp =1.013 [bar]

Lower

lambda

point

Tλ_Lower =2.177 [K]

Pλ_Lower =50.36

[mbar]

Upper

lambda

point

Tλ_upper =1.763

[K] Pλ_upper

=30.13 [bar]

70

N2相图

71

Change in volume from liquid at normal

boiling point to gas at 300 K and 1 atm

72

Material Properties 材料低温性能

Some suitable materials for cryogenic use include:

• Austenitic stainless steels e.g. :304, 316L, 304L, 321

• Aluminum alloys e.g. :6061, 6063, 5083, 1100

•Copper e.g. :OFHC, ETP and phosphorous deoxidized, 磷青铜、铍青铜等,

TU2/TP2/T2

•Brass (H62/H65)

•Fiber reinforced plastics: G –10, s2-glass, carbon fiberglass, etc.

•Niobium & Titanium (frequently used in superconducting RF systems)

•Invar (Ni /Fe alloy) useful in making washers due to its lower coefficient of

expansion

•Indium (used as an O ring material)

•Kapton and Mylar (used in Multilayer Insulation and as electrical insulation)

• Quartz (used in optical windows)

•……

73

Thermal Expansion Coefficient

α=1/L (δL/δT)

•Large amounts of contraction can occur when materials are cooled to cryogenic

temperatures.

•α goes to 0 at 0 slope as T approaches 0 K

•α is T independent at higher temperatures

•For practical work the integral thermal contraction is more useful

Points to consider:

•Impact on alignment

•Development of interferences or gaps due to dissimilar materials

•Increased strain and possible failure

•Impact on wiring

•Most contraction occurs above 77 K

Thermal Stress:Secondary stress

Th

E (T ) L dT

Tc

74

75

Integral Thermal Contraction

Roughly speaking:

•Metals – 0.5% or less

•Polymers – 1.5 – 3%

•Some amorphous materials have 0 or even negative

thermal contraction

76

Thermal Conductivity

77

2 K Cryo-system

How to make 2K Super-fluid Helium ? 减压降温

Saturated Vapor Pressure of Helium

latent heat of vaporization

1.2 bar

4.4 K

0.03 bar

2.0 K

Temperature [K]

Enthalpy [ J / g ]

Pressure [bar]

Gas State

20 J / g

Liquid State

2.0 K

Temperature [K]

Liq. He 1 l

1 / 8 kg

1 / 8 x 20 = 2.5 kJ

Liq. He 1 l / hr -- 2.5 / 3.6 = 0.7 W

Use the latent heat of vaporization of helium

Cooling Power

Cold Pump

Large System CEBAF, LHC, ….

Warm Pump

Small System KEK

1W -- Liq. He Consumption 1.4 l /hr

78

Pumping

(Warm

or

Cold Pump)

JT1

Normal Helium

T~ 4.2 K

JT - Heat

Exchanger

4.2 K

2.2 K

JT2

89 %

62 %

Super-fluid

T~ 1.8 K

79

Cooling schemes

Refrigerators operating at 2K or lower need to pump on a liquid helium bath to

lower the saturation vapor pressure below 31 mbar. The pumping (helium

compression to atmospheric pressure) can be done at warm or at cryogenic

temperatures or in a mixed mode. Due to additional pressure drop in the helium lines

and the heat exchangers, a pressure ratio of nearly 40 to reach atmospheric pressure

is needed.

When planning refrigeration at sub-atmospheric pressure, one has to decide,

whether pure warm compression, or pure cold compression, or partly cold with

subsequent warm compression shall be applied. Accordingly, several types of

thermal cycles are generally considered to produce refrigeration below 2 K, the “purewarm” compression cycle based on multiple vacuum pumps, the “pure-cold”

compression cycle based on multistage cold compressors (generally 4~5 stages), and

the “mixed” compression cycle based on a combination of cold compressors in series

with warm sub-atmospheric compressors.

For the layout of the helium system, capital costs, operating expenses, capacity of

available pumping facilities must be taken into considerations. The most important

criteria for the choice is the cooling power required at sub-atmospheric

pressure.

80

Cold Box

4.4K LHe I

Cold Box

4.4K LHe I

81

Cold Box

4.4K LHe I

Cold Box

4.4K LHe I

82

Homework

83

Determine the ideal-work requirement for the liquefaction of

nitrogen, beginning at 101.3 kPa and 300K.

From the T-s diagram of nitrogen:

hH = 462 [J/g] at 101.3 kPa and 300K

hf = 29 [J/g] at 101.3 kPa and 77K

sH = 4.42 [J/g-K] at 101.3 kPa and 300K

sf = 0.42 [J/g] at 101.3 kPa and 77K

84

References

85

86

87

88