B - Universitas Sebelas Maret

advertisement

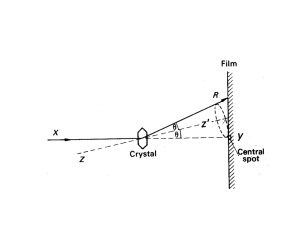

X-ray diffraction Equipment Bruker D8 Analytical X-ray Systems X-ray beam source Bruker D8 ADVANCE uses an x-ray tube with a Cu anode as the primary x-ray beam source. In this component x-rays are generated when a focused electron beam accelerated across a high voltage field bombards a stationary solid Cu target. As electrons collide with atoms in the target and slow down, a continuous spectrum of x-rays is emitted, which is termed Bremsstrahlung radiation. The high energy electrons also eject inner shell electrons in atoms through the ionization process. When a free electron fills the shell, an x-ray photon with energy characteristic of the target material is emitted. Common targets used in x-ray tubes include Cu and Mo, that emit 8 keV and 14 keV x-rays with corresponding wavelengths of 1.54 Å and 0.8 Å, respectively. Wavelengths for X-Ray source Copper Anodes Bearden (1967) Holzer et al. (1997) Cobalt Anodes Bearden (1967) Holzer et al. (1997) Cu Ka1 1.54056Å 1.540598 Å Co Ka1 1.788965Å 1.789010 Å Cu Ka2 1.54439Å 1.544426 Å Co Ka2 1.792850Å 1.792900 Å Cu Kb 1.39220Å 1.392250 Å Co Kb 1.62079Å 1.620830 Å Cr Ka1 2.28970Å 2.289760 Å Molybdenum Anodes Chromium Anodes Mo Ka1 0.709300Å Mo Ka2 0.713590Å 0.713609 Å Cr Ka2 2.293606Å 2.293663 Å Mo Kb 0.632288Å 0.632305 Å Cr Kb 2.08487Å 2.084920 Å Often quoted values from Cullity (1956) and Bearden, Rev. Mod. Phys. 39 (1967) are incorrect. 0.709319 Å Values from Bearden (1967) are reprinted in international Tables for XRay Crystallography and most XRD textbooks. Most recent values are from Hölzer et al. Phys. Rev. A 56 (1997) BRAGG’s EQUATION Deviation = 2 Ray 1 Ray 2 d The path difference between ray 1 and ray 2 = 2d Sin For constructive interference: n = 2d Sin θ - 2θ Scan The θ - 2θ scan maintains these angles with the sample, detector and X-ray source Normal to surface Only planes of atoms that share this normal will be seen in the θ - 2θ Scan NanoLab/NSF NUE/Bumm Powder diffraction data can be collected using either transmission or reflection geometry, as shown below. Because the particles in the powder sample are randomly oriented, these two methods will yield the same data Reflection Occurs from surface Takes place at any angle ~100 % of the intensity may be reflected Diffraction Occurs throughout the bulk Takes place only at Bragg angles Small fraction of intensity is diffracted Incident X-rays SPECIMEN Fluorescent X-rays Electrons Scattered X-rays Coherent From bound charges Heat Compton recoil Photoelectrons Incoherent (Compton modified) From loosely bound charges Transmitted beam X-rays can also be refracted (refractive index slightly less than 1) and reflected (at very small angles) Refraction of X-rays is neglected for now. How does it work? In powder XRD method, a sample is ground to a powder (±10µm) in order to expose all possible orientations to the X-ray beam of the crystal values of , d and for diffraction are achieved as follows: 1. is kept constant by using filtered X- radiation that is approximately monochromatic. 2. d may have value consistent with the crystal structure 3. is the variable parameters, in terms of which the diffraction peaks are measured. How does XRD Works??? Every crystalline substance produce its own XRD pattern, which because it is dependent on the internal structure, is characteristic of that substance. The XRD pattern is often spoken as the “FINGERPRINT” of a mineral or a crystalline substance, because it differs from pattern of every other mineral or crystalline substances. Basic Component Of XRD Machine Therefore any XRD machine will consist of three basic component. • Monochromatic X-ray source () • Sample-holder (goniometer). • Data collector- such as film, strip chart or magnetic medium/storage. By varying the angle , the Bragg’s Law conditions are satisfied by different d-spacing in polycrystalline materials. Plotting the angular positions and intensities of the resultant diffraction peaks produces a pattern which is characterised of the sample X-ray Components A typical X-ray instrument is built by combining high performance components such as Xray tubes, X-ray optics, X-ray detectors, sample handling device etc. to meet the analytical requirements. A consequent modular design is the key to configure the best instrumentation. . Diffraction Pattern Collected Where A Ni Filter Is Used To Remove Kβ Kb E keV h hc 6.02 Typical experimental data from Bruker XRD TiO2 2-theta I 14000 101 Anatase 12000 10000 8000 6000 4000 110 Rutile 2000 0 0 10 20 30 2 40 50 60 70 intensitas 20 405 20.05001 357 20.10002 381 20.15002 371 20.20003 376 20.25004 356 20.30005 370 20.35006 395 20.40006 373 20.45007 335 20.50008 397 101 Anatase 110 Rutile Examples of 3D Reciprocal Lattices weighed in with scattering power (|F|2) SC 001 011 101 Lattice = SC 111 000 010 100 No missing reflections 110 Reciprocal Crystal = SC Figures NOT to Scale 002 022 BCC 202 222 011 101 000 Lattice = BCC 020 110 200 100 missing reflection (F = 0) Weighing factor for each point “motif” 220 Reciprocal Crystal = FCC F2 4 f 2 Figures NOT to Scale 002 022 FCC 202 222 111 Lattice = FCC 020 000 200 100 missing reflection (F = 0) 220 110 missing reflection (F = 0) Weighing factor for each point “motif” Reciprocal Crystal = BCC F 2 16 f 2 Figures NOT to Scale Sample preparation Make a mine powder • Sample holder Side Drift Mount Designed to reduce preferred orientation – great for clay samples, (and others with peaks at low 2-theta angles) Film, pellets, crystals mineral specimens Sample holder Specimen Holders for X-ray Diffraction Match The Sample/Measurement Conditions With The Diffraction Pattern 1 2 3 Misinterpreting X-Ray Diffraction Results Rock Salt JCPDF# 01-0994 Why are peaks missing? 200 220 111 222 311 • The sample is made from Morton’s Salt • JCPDF# 01-0994 is supposed to fit it (Sodium Chloride Halite) It’s a single crystal 200 220 111 222 311 2 At 27.42 °2, Bragg’s law fulfilled for the (111) planes, producing a diffraction peak. The (200) planes would diffract at 31.82 °2; however, they are not properly aligned to produce a diffraction peak The (222) planes are parallel to the (111) planes. A random polycrystalline sample that contains thousands of crystallites should exhibit all possible diffraction peaks 200 220 111 222 311 2 2 2 • For every set of planes, there will be a small percentage of crystallites that are properly oriented to diffract (the plane perpendicular bisects the incident and diffracted beams). • Basic assumptions of powder diffraction are that for every set of planes there is an equal number of crystallites that will diffract and that there is a statistically relevant number of crystallites, not just one or two. Intensity (a.u.) Which of these diffraction patterns comes from a nanocrystalline material? Hint: Why are the intensities different? 1o 0.0015o 66 67 68 69 70 71 72 73 74 2 (deg.) These diffraction patterns were produced from the exact same sample The apparent peak broadening is due solely to the instrumentation 0.0015° slits vs. 1° slits optical cofigurations Scan speed ( stepsize) http://prism.mit.edu/xray Crystallite Size Broadening B2 Scherrer’s Formula Peak Width B(2) varies inversely with crystallite size The constant of proportionality, K (the Scherrer constant) depends on the how the width is determined, the shape of the crystal, and the size distribution 0.94 t cos the most common values for K are 0.94 (for FWHM of spherical crystals with cubic symmetry), 0.89 (for integral breadth of spherical crystals with cubic symmetry, and 1 (because 0.94 and 0.89 both round up to 1). K actually varies from 0.62 to 2.08 For an excellent discussion of K, refer to JI Langford and AJC Wilson, “Scherrer after sixty years: A survey and some new results in the determination of crystallite size,” J. Appl. Cryst. 11 (1978) p102-113. Remember: Instrument contributions must be subtracted Scherrer’s Formula K t B cos B t = thickness of crystallite / crystallite size K = constant dependent on crystallite shape (0.89) = x-ray wavelength B = FWHM (full width at half max) or integral breadth B = Bragg Angle Scherrer’s Formula What is B? B = (2θ High) – (2θ Low) Peak 2θ high 2θ low B is the difference in angles at half max Noise When to Use Scherrer’s Formula Crystallite size <1000 Å Peak broadening by other factors Causes of broadening • Size • Strain • Instrument If breadth consistent for each peak then assured broadening due to crystallite size K depends on definition of t and B Within 20%-30% accuracy at best Sherrer’s Formula References Corman, D. Scherrer’s Formula: Using XRD to Determine Average Diameter of Nanocrystals. Scherrer’s Example Au Foil 10000 9000 8000 98.25 (400) 7000 Counts 6000 5000 4000 3000 2000 1000 0 95 95.5 96 96.5 97 97.5 98 98.5 2 Theta 99 99.5 100 100.5 101 101.5 102 Scherrer’s Example 0.89 t B cos B t = 0.89*λ / (B Cos θB) λ = 1.54 Ǻ = 0.89*1.54 Ǻ / ( 0.00174 * Cos (98.25/ 2 ) ) = 1200 Ǻ B = (98.3 - 98.2)*π/180 = 0.00174 Target Metal Of Ka radiation (Å) Mo 0.71 Cu 1.54 Co 1.79 Fe 1.94 Cr 2.29 Simple Right! Methods used to Define Peak Width Full Width at Half Maximum (FWHM) the width of the diffraction peak, in radians, at a height half-way between background and the peak maximum Integral Breadth the total area under the peak divided by the peak height the width of a rectangle having the same area and the same height as the peak requires very careful evaluation of the tails of the peak and the background 46.7 46.8 46.9 47.0 47.1 47.2 47.3 47.4 47.5 47.6 47.7 47.8 47.9 2 (deg.) Intensity (a.u.) FWHM Intensity (a.u.) 46.7 46.8 46.9 47.0 47.1 47.2 47.3 47.4 2 (deg.) 47.5 47.6 47.7 47.8 47.9 Remember, Crystallite Size is Different than Particle Size A particle may be made up of several different crystallites Crystallite size often matches grain size, but there are exceptions http://prism.mit.edu/xray Anistropic Size Broadening The broadening of a single diffraction peak is the product of the crystallite dimensions in the direction perpendicular to the planes that produced the diffraction peak. http://prism.mit.edu/xray A large crystallite size, defect-free powder specimen will still produce diffraction peaks with a finite width The peak widths from the instrument peak profile are a convolution of: X-ray Source Profile • Wavelength widths of Ka1 and Ka2 lines • Size of the X-ray source • Superposition of Ka1 and Ka2 peaks Goniometer Optics • Divergence and Receiving Slit widths • Imperfect focusing • Beam size • Penetration into the sample http://prism.mit.edu/xray Intensity (a.u.) Instrumental Peak Profile 47.0 47.2 47.4 47.6 47.8 2 (deg.) Patterns collected from the same sample with different instruments and configurations at MIT B ( FWHM ) Bi Bc Bs BSF ... What Instrument to Use? The instrumental profile determines the upper limit of crystallite size that can be evaluated if the Instrumental peak width is much larger than the broadening due to crystallite size, then we cannot accurately determine crystallite size For analyzing larger nanocrystallites, it is important to use the instrument with the smallest instrumental peak width Very small nanocrystallites produce weak signals the specimen broadening will be significantly larger than the instrumental broadening the signal:noise ratio is more important than the instrumental profile http://prism.mit.edu/xray Smaller Crystals Produce Broader XRD Peaks Comparison of Peak Widths at Crystallite Sizes Crystallite Size FWHM (deg) 100 nm 0.099 50 nm 0.182 10 nm 0.871 5 nm 1.745 Rigaku XRPD is better for very small nanocrystallites, <80 nm (upper limit 100 nm) PANalytical X’Pert Pro is better for larger nanocrystallites, <150 nm http://prism.mit.edu/xray Decrease crystallite size A = anatase, R = rutile, B = brokite, (B)=TiO2(B) Wahyuningsih, S., 2009 Polycrystalline films on Silicon Why do the peaks broaden toward each other? Solid Solution Inhomogeneity Variation in the composition of a solid solution can create a distribution of d-spacing for a crystallographic plane ZrO2 46nm CeO2 19 nm Intensity (a.u.) 45 46 CexZr1-xO2 0<x<1 47 48 49 2(deg.) 50 51 52 Many factors may contribute to the observed peak profile Instrumental Peak Profile Crystallite Size Microstrain Non-uniform Lattice Distortions Faulting Dislocations Solid Solution Inhomogeneity The peak profile is a convolution of the profiles from all of these contributions http://prism.mit.edu/xray Thank you for your attending! Workshop & Analysis Informations: Dr. Sayekti Wahyuningsih, M.Si Dr. Yoventina Iriani, M.Si Laboratorium MIPA Terpadu FMIPA Universitas Sebelas Maret Phone / fax : (0271) 663375