Mario Farrugia Nicholas Grech Marlon Chircop Jean Paul Azzopardi

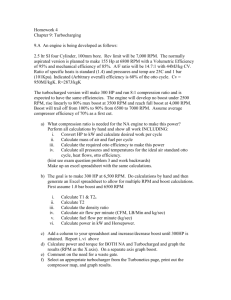

advertisement

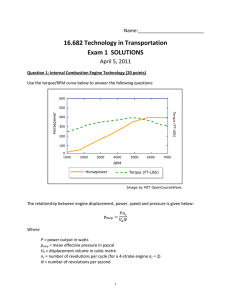

Simulation and Implementation of Turbocharging a 600cc Engine for Formula SAE Mario Farrugia Nicholas Grech Marlon Chircop Jean Paul Azzopardi 1 Introduction •FSAE restrictor •Turbocharging PST vs CPT •Garrett Honeywell GT 15V vs GT 12 •Kawasaki 600cc engine 2 Objectives •Simulations in Wave of Turbocharged engine •Implementation of turbocharger • Dynamometer testing of turbocharged engine 3 Choice of Turbocharger •Garrett donate GT 12 fixed geometry •And also GT15V variable geometry •Choice of GT 15 V because some experience was gathered at Oakland University (Michigan) on GT 12, so now took the variable geometry challenge 4 Variable Geometry Turbine • 5 The vane mechanism • 6 1D engine Simulation Wave® 7 Simulations •Simulations in Wave of Turbocharged engine •Started from naturally aspirated simulations SAE papers 2005-010025 and 2006-01-3651 8 Compressor Map GT 15V donated by Garrett Honeywell 9 The Variable Geometry Turbine Map * W FU LL R AN G E TU R B IN E M AP - ISO W O R K LIN E N °4 TU R BIN E: G T15V (7.9 m m shaft) - T109(39) - 58 Trim - 0,42 A/R W T1T / 519 P1T / 29.92 1 % 8 % 89 27 8 rp m 100 a rp m t 0,9 % 428 m at 1,2 rp 111460 T1T / 519 % 0.4 pm 5 9 % Nphy 122550rpm at 0,9 % 84 5r 0.45 0.5 8rp m at 7 04 0, 0,9 66 1 ,1 % at 78 m rp at at NT c o rre c te d m a s s flo w (lb /m in ) 55 60 0.55 6 0.6 O pen 4/5 open 5 0.6 3/5 open 4 2/5 open 0.55 0.5 3 1/5 open 0.45 1/10 open 2 0.4 C losed 1 open 4/5open 3/5open 2/5open 1/5open 1/10open closed 0 1 1.5 2 2.5 Turbine Expansion R atio 3 3.5 10 Wave Model PST with Intercooling, Kawasaki 600cc WAVE model 11 Effect of Compression Ratio on Knock 0.12 Knock Magnitude 0.1 CR 11 0.08 CR 10 0.06 CR 9 CR 8 0.04 0.02 0 2500 4500 6500 8500 10500 12500 Engine Speed (rpm) 12 Effect of Compression Ratio on Torque 70 65 60 Torque (Nm) 55 50 45 40 Naturally Aspirated CR 11 CR 10 CR 9 CR 8 35 30 25 20 2500 4500 6500 8500 10500 12500 Engine Speed (rpm) Kawasaki 600cc engine with GT 15V 13 Various PST turbocharging setups 75 65 Torque (Nm) 55 45 Boost 1.5bar Boost 1.5bar, intercooled 35 Boost 1.5bar, intercooled, modified valve timing Boost 1.5bar, intercooled, modified valve timing, tuned exhaust length 25 Final model, CR 7 Naturally Aspirated 15 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 Engine Speed (rpm) 14 Exhaust Setup 15 Inlet Manifold 16 Throttle Body and Restrictor 17 Timing Chain Length Inspection 18 Machined Decompression Plate CNC machined decompression plate, 3mm aluminium sheet 19 Mechanical Seal on Compressor Side CNC machined compressor back plate and the chosen mechanical seal components 20 Scavenge Oil Pump and Breaking Oil Siphon Turbo Oil Pan Turbo Oil Pan 21 Cam Sensor Novel Implementation •A strong, 250gr rated pull force, magnet was inserted into a bolt and swage locked in the bolt. •Magnet has north and south on the axis •The bolt was installed in one of the cam sprocket OEM holes •Cam signal is trace 1, crank signal is trace 2 22 Scavenge Oil Pump and Breaking Oil Siphon •Oil supply taken from highest point, and also a point that has connection to atmosphere when engine is stopped so that siphon is broken 23 Dynamometer Testing 24 Exhaust Gas Temperature variation with Spark Timing • EGT drops with more advanced timing 25 Air Temperature and Manifold Absolute Pressure • Air temperature increase with rise in boost pressure as expected 26 Charge Air Cooler •Direction 1 is shorter than direction 2 , so direction 2 was used to have more effectiveness of the heat exchanger. 27 TPS Compensation On Fuel Quantity TPS % Compensation 0 45 5 45 15 50 25 55 50 100 75 100 100 100 •The TPS compensation effectively generates a low throttle map or sometimes called zero throttle map. •Engine was with MAP as the load parameter but due to large cam overlap high exhaust residuals exist at idle which result in high MAP Values at idle as discussed in SAE 2005-01-0025 . 28 Torque measurements •Measurement of Torque on dynamometer with increase in RPM and resulting boost pressures 29 Steady State: Variation of Electrical Power Input with Frequency • Limited capability to control rpm and MAP 30 Conclusion 31 Concluding Remarks •Engine was successfully run •Oil problems solved by mechanical seal and breaking of siphon •Charge air cooler controlled temperature well •TPS compensation to counteract High MAP values at idle •External Wastegate implemented in ongoing project to have a stable system on dyno. Thank you Questions ? 32