CRIOCM2012--Steel Sc..

advertisement

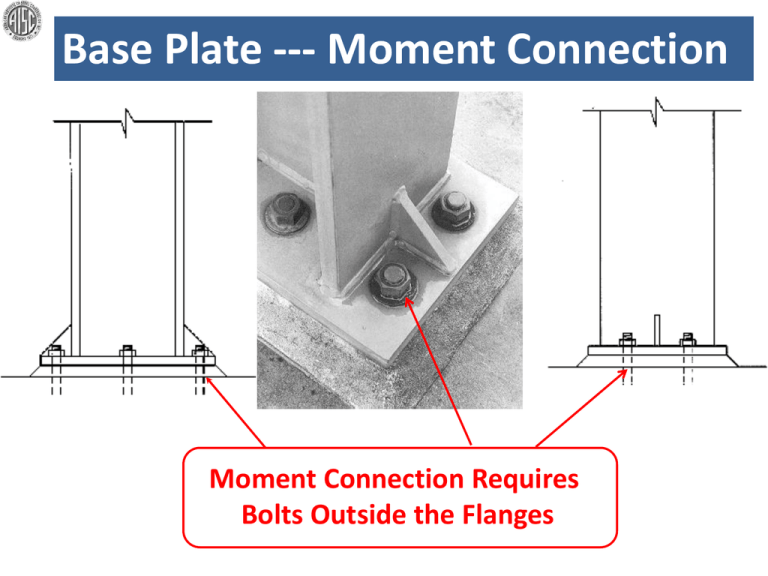

Base Plate --- Moment Connection Moment Connection Requires Bolts Outside the Flanges Base Plate --- Moment Connection The Triangular Stiffener Plate increases Shear Strength of Connection and Bending Strength of Base Plate Base Plate --- Moment Connection Moment Connection Bolts Outside the Flanges Base Plate --- Moment Connection Additional Plates and Welds Needed for Large Flange Forces Base Plate --- Pipe Column This Connection is Considered as a Pin Connection Base Plate --- Pipe Column Large Point Load Requires Web Stiffener Plates Moment Connection --- Beam Splice Flange Plate for Transferring Compressive Force Due to Bending Moment Connection --- Beam Splice Flange Plate to Transfer Tensile Force Due to Bending Moment Connection --- Beam Splice Web Plate for Transferring Shear Column Splice --- Bolted Flange Plates are Shop Welded Column Splice --- Bolted Flange Plates are Field Bolted Column Splice --- Welded Web Plate is Shop Welded Column Splice --- Welded Web Bolts for Erection Fit-up After Lowering Upper Column it is Field Welded Moment Connection to Column Flange --- Field Welded Web Plate is Shop Welded to Column Flange Moment Connection to Column Flange --- Field Welded Backing Rods Needed for Groove Welds Moment Connection to Column Flange --- Field Welded Beam is Then Attached Using Full Penetration Field Groove Welds Moment Connection to Column Web Welded Flange Plates at Top and Bottom are Shop Welded Moment Connection to Column Web Welded Web Plate is Shop Welded Moment Connection to Column Web Welded Beam is Field Welded after sliding in The Flange plates Moment Connection to Column Web Welded Field Weld After Sliding the Beam in Flange Plates Moment Connection --- End Plate End Plate Shop Welded to the Beam Moment Connection --- End Plate Tension Side Bolts Compression Side Bolts All Bolts Installed in Field Shear Connection --- Bolted Seat No Direct Connection of Beam and Column Flanges. Low Rigidity of Angles makes it a Shear Connection Shear Connection --- Bolted Seat Bolted Seat Angle helps Placing and Bolting of Beam Shear Connection --- Bolted Seat Lower Seat Angles Resist All the Shear so Bigger Lower Seat and More Bolts are Needed Shear Connection --- Welded Seat Seated Beam Shear Connection Shear Connection --- Welded Seat Seat Angle Shop Welded and Field Bolted Shear Connection --- Welded Seat Web Angle is Only for Stability and carries No Load Shear Connectors for Composite Beam Shear Studs welded to Beam Flanges in Field for making Concrete Deck integral to Steel Shear Connection --- Double Sided Left Side Angles with Two Bolts Floor Beam on Left Side of Girder Shear Connection --- Double Sided Right Side Angles with Three Bolts Floor Beam on Right Side of Girder Shear Connection --- Double Sided View From the Left Side Floor Beam View From the Right Side Floor Beam Shear Connection --- Double Web Angles Shop & Field Bolted One Sided Floor Beam to Girder Shear Connection Shear Connection --- Single Angle Note Shop Weld And Field Bolts For Lightly Loaded Channels Single Angle Shear Connection can be used Shear Connection --- Skewed A Single Angle Shear Connection For a Skewed Channel Truss --- Shop Welded, Field Bolted Note Shop Welds Truss --- Shop Welded, Field Bolted And Field Bolts For Connecting the Truss to Column Truss --- Shop Welded, Field Bolted Double Angle Members for Top Chord, Bottom Chord and Web Truss --- Shop Welded, Field Bolted Cold Formed Z-Shape Purlin