TSF - design

advertisement

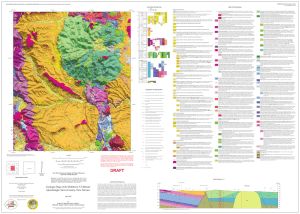

TERRAMIN AUSTRALIA Limited Angas Zinc Project Tailings Storage Facility Overview • Long presentation – may of necessity be a bit technical • Why we need a Tailings Storage Facility (TSF) • The Design Process – Requirements – Guidelines – Testwork • • • • • Tailings Handling method Water management Design selection Closure Location – Flood Plain Angas Zinc Project: Tailings storage • Mining & processing ore creates nonsaleable by-products • “Tailings”- fine sand of the waste rock • Often combined with water • Stored close to site of processing • About 40% goes back underground as “cemented backfill” • However, need to design for “worst case” THE TSF DESIGN PROCESS TSF Guidelines • ANCOLD Guidelines used, no current Guidelines in SA. ANCOLD draws substantially from WA “Guidelines on the Safe Design & Operation Standards for Tailings Storage” but goes further in the area of dam design • PIRSA -EPA “Guidelines for the Management of Tailings” at the proposed Angas Zinc Project, Strathalbyn, SA TSF - design • Australian Tailings Consultants • TSF objective: – No contamination of natural water drainage systems, ground water, land and soils either on or off site during operation and indefinitely post closure caused by mine ore or waste material. TSF The Testwork • • • • • • • • • Test pits In-situ permeability testing. Lab. testing of soils. Geochemical & geotechnical testing of simulated tailings. Impoundment layout & bank design - modeling. Seepage analyses, assessment of groundwater impact & design of proposed mitigating measures. Location, design & installation of groundwater monitoring bores. Water mgt. both process & rainfall. Proposals for TSF closure & rehabilitation*** TSF Tailings Handling Options Two Options: • Un-thickened tailings – Majority of TSF in Australia • Thickened tailings – Few places in the World using very high density tails deposition – used when water is scarce, ease of closure*** Advantages of thickened tailings • • • • Low water demand No water pond to attract birds Tailing surface crust stops dusting Beach area dries rapidly allows early access. • Allows for progressive closure TSF - Thickened tailings • Wheaton River’s, Peak Mine - Cobar Thickened tailings • Wheaton River’s, Peak Mine - Cobar Water management TSF - Water Management TSF - Water management: Water from TSF to Plant TSF - Water management Summary • Divert all surface flows from surrounding area around the TSF • Dam design allows for the catchment of a 1:100yr 5 day storm event • No water pond on TSF The TSF Design Selection TSF Design Risk Analysis TSF-Risk Analysis TSF location & detail QuickTime™ and a TIFF (LZW) decompressor are needed to see this picture. TSF construction: base layer TSF options- detail • Proposed Design Option: Decant well TSF Design Design Summary: • HDPE liner (base and cap) • Thickened tailings • Liner ensures TSF design requirement • Placement: beyond 1:100 ARI flood level • Footprint:15ha • World’s Best Practice TSF Closure TSF Closure: capping layers TSF Closure TSF Closure • Closure is important aspect for the longer term environmental considerations • Impervious cover liner • Earthworks – reshaping, topsoil • Rapid revegetation • Risk based closure plan used Flood Plain Modelling TSF placement to meet outcomes • 100m from 1:100 ARI flood plain • Flood modelling • Tonkin- Chris Purton: Senior Meteorologist Historic Rainstorms and Floods at Strathalbyn • The largest rainfall event in 145 years was the three day rainstorm ending 9am, 26 January 1941 – 217mm • The December 1992 monthly rainfall was 171.2 mm, which was the second highest monthly rainfall on record. The two-day total of 116 mm and the three-day total of 124 mm both had an ARI of just under 100 years Historic Rainstorms and Floods at Strathalbyn 1:100yr ARI Flood Plain 1:100yr ARI Flood Plain • Conclusion • Since the terrain rises steeply from the maximum indicated floodplain extent (without a bund) towards the proposed Tailing Storage Facility site, it is certain that the floodplain extent will not extend any further into the mining lease site than is shown in Figure 1.3 Tailings Storage Facility Summary • Every TSF design has some unique issues • To design a TSF you must do a lot of standard tests to; – Tails characterisation ,sg, sizings, settling rates geochem., etc. – Soil characterisation geotechnical stability, permeability, etc – Seismic susceptibility • There is nothing out of the ordinary in the testwork required in the design for the TSF – follow the relevant codes • What is required is the first of its kind in the world