SESM3004 Fluid Mechanics

advertisement

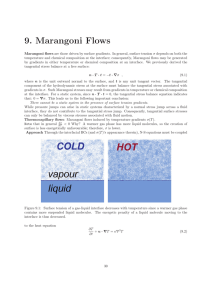

Lecture 17: Natural (Free) convection http://www.youtube.com/watch?v=qIlcXp-cKHg 1. Assume that gravitational field affects the flow divv 0 v p v v v g t T v T T t 1 2. Statics: p0 g 0 0 3. We separate the static parts and the non-static contributions: p p 0 p , 0 4. Assume that p 1, 1 p0 0 5. Linearization of the pressure term p0 p1 0 p0 p p0 p0 p p0 p 2 0 0 1 0 0 0 0 0 p 6. Substituting this into Navier-Stokes equation p p p v v v v g t v p or v v g v t 0 0 2 0 0 0 0 0 2 7. In incompressible flow, density variations are due to temperature nonisothermalities T 0 0 0 v p v v T g v t 0 Finally, the governing equations for thermal convection in Boussinesq approximation v p v v v T g t 0 T v T T t div v 0 Let us non-dimensionalise these equations. 3 Dimensions of the viscosity and thermal conductivity coefficients m2 s 1 K Dimension of the heat expansion coefficient Gravity acceleration g gk L -- length scale (typical size) L2 -- time-scale (also called convective time scale) v L L -- scale of velocity p v -- scale of pressure L 2 2 0 T 0 -- scale of temperature (Θ is the typical temperature difference) Non-dimensionalisation t dim tnon dim , v dim v v non dim , pdim v pnon dim , Tdim Tnon dim 4 Non-dimensionalization of the Navier-Stokes equation: v v v 2 v v 0 v 2 p v v T gk t or L L 0 L2 v gL v v p v GrT k , Gr t 3 2 Heat transfer equation, T v v T T t L L 2 or T 1 v T T , Pr t Pr Non-dimensionalization of the continuity equation is trivial: divv 0 5 Non-dimensionalised equations of thermal convection v v v p v GrT k t T 1 v T T t Pr divv 0 Non-dimensional parameters: gL -- Grashof number (defines the strength of the forcing Gr (buoyancy) term; characterises intensity of the convective flow) 3 2 Pr -- Prandtl number (characterises the fluid properties; defines the relative importance of thermal conduction and convection as two mechanisms of heat transfer, Pr>>1: convection 6 dominates, Pr<<1: convection can be disregarded) Czochralski process When the silicon is fully melted (~15000C), a small seed crystal mounted on the end of a rotating shaft is slowly lowered until it just dips below the surface of the molten silicon. The seed crystal's rod is slowly pulled upwards. Silicon ingot The Czochralski process is a one of the methods of crystal growth from melt, used to obtain single crystals of semiconductors (e.g. silicon, germanium and gallium arsenide), metals (e.g. palladium, platinum, silver, gold), salts, and synthetic gemstones. Main difficulty: strong convective flows in the melt. From one hand, convection makes the melt more uniform, which is positive. From another hand, strong flows near the crystallization plane introduce crystal defects. Convection is controlled by rotation/vibration of ingot and crucible, by 7 magnetic field, … Solutal convection Consider incompressible isothermal fluid flow with an admixture. Equation of mass conservation for an impurity: C (this equation is valid for not very large C) v C DC t Diffusion coefficient Variations in density can be caused by admixture: C 0 0 v p v v v Cg t 0 C v C DC t divv 0 P.S. If flow is non-isothermal, the thermosolutal (or double-diffusive) convective flow is induced. 0 Equations of solutal convection: 8 Lecture 1Flows driven by surface tension gradients Spatial variations in surface tension result in added tangential stresses at an interface, giving rise to fluid motions in the underlying bulk liquids. The motion induced by tangential gradients of surface tension is termed the Marangoni effect. Examples: the camphor ball ‘dances’ on a water surface (http://www.youtube.com/watch?v=Pe88T45VdR8), the calming effect of ‘oil troubled waters’ (http://www.youtube.com/watch?v=00PPPt7EJqo). 9 This motion is induced at an interface, where, besides the normal force, there is another force tangential to the surface, f t . Adding this force, we obtain the following boundary condition 1 1 p p n n 2 1,ik 2 ,ik k 1 i R R x i 1 2 n is the unit normal vector directed into medium 1. T C q The surface tension coefficient is function of temperature; the thermocapillary flows are induced. function of concentration; the difusocapillary flows. function of electric charge; the electrocapillary flows. 10 Thermocapillary motion in a thin liquid layer The thermocapillary motion generated in an open rectangular shallow pan with a very thin layer at the bottom. The difference in side wall temperatures results in a temperature gradient along z T2 the surface. For liquids, g T1 (cold) (hot) 0 h2 T h(x) h1 l h x l α α2 α1 1 The flow in nearly lateral. Any flow nonuniformities at the side walls are small and the flow is essentially 2D. 11 x Except at the side walls, which are far removed from the bulk flow, the vertical velocity component is very much smaller than the horizontal component and any effects of the free surface curvature may be neglected. v uz ,0,0 R1 R2 We assume that the liquid layer is thin enough to neglect inertial effects, implying Re<<1 (‘shallow water’ approximation). Governing equations: x-projection of the momentum equation, z-projection, p 2u 2 x z p g z The continuity equation (in integral form) for the fully developed flow is (1) (2) h x u z d z 0 0 (3) 12 Boundary conditions: 1. Bottom (z=0): u 0 2. free surface (z=h): Or, for our flow, (4) patm p ni ik nk x i u d z dx (5) p patm (6) n 0,0,1 Integration of (1) with the use of (4) and (5) gives d p 1 p 2 h z z x 2 x dx u (7) Integration of (2) with the use of (6) gives p patm g h z (8) 13 (8) specifies the relation between the pressure gradient and variation of free surface height in the x-direction as p dh g x dx (9) By using (7) and (9), condition (3) results in Or, 1 g 3 h 2 h12 The velocity profile: d 2 dh gh dx 3 dx Here, we assumed that α=α1 and h=h1 at x=0. umax z 3 z d u 1 2 2 h dx u max h d 4 dx 14 The requirement Re<<1 may be expressed as Re u max h1 h12 d 1 4 dx 4 2 h d dx or 2 1 The variation of α with T for liquids is close to linear. For water, mN 0.15 T m K 2 m 106 s and Thus with mN This would d 15 2 give a value dx m dT K 100 dx m 103 kg m3 Hence, h1 1mm We did not consider the gravity-driven convection. The gravity between the gravity and capillary forces is defined by the Bond number: 2 h1 gh12 Bo 1 c Here, g 2 c -- capillary length 15 For water/air interface, 73mN . And, for our configuration, Bo 0.3 1 m This means that, for the configuration examined, the flows driven by the surface tension effect (Marangoni convection) dominate (in comparison with the gravity-driven convective flows). The surface tension gradients can be important in such very thin layers of mm size or less, or in a reduced gravity environment. For example, a crystal grown from its melt under reduced gravity is governed by convection driven by thermally induced surface tension gradients rather than buoyancy forces. 16 Ludwig Prandtl (4 February 1875, Freising, Upper Bavaria – 15 August 1953, Gottingen) was a German scientist. He was a pioneer in the development of rigorous systematic mathematical analyses which he used to underlay the science of aerodynamics, which have come to form the basis of the applied science of aeronautical engineering. In the 1920s he developed the mathematical basis for the fundamental principles of subsonic aerodynamics in particular. 17 Franz Grashof (July 11, 1826 in Dusseldorf October 26, 1893 in Karsruhe) was a German engineer. He was a professor of Applied Mechanics at the Technische Hochschule Karlsruhe. He developed some early steam-flow formulas but made no significant contribution to free convection. Joseph Valentin Boussinesq (13 March 1842, Saint-Andre-deSangonis, France –Died 19 February 1929, Paris, France) was a French mathematician and physicist who made significant contributions to the theory of hydrodynamics, vibration, light, and heat. Carlo Giuseppe Matteo Marangoni (29 April 1840, Pavia Italy – 14 April 1925, Florence, Italy) was an Italian physicist. He held a position of High School Physics Teacher at the Liceo Dante (Florence) for 45 years, until retirement in 1916. He mainly studied surface phenomena in liquids and also contributed to 18 meteorology. Jan Czochralski (23 October 1885 – 22 April 1953) was a Polish chemist who invented the Czochralski process, which is used for growing single crystals and in the production of semiconductor wafers. He was educated at Charlottenburg Polytechnic in Berlin, where he specialized in metal chemistry. Czochralski discovered the Czochralski method in 1916, when he accidentally dipped his pen into a crucible of molten tin. He immediately pulled his pen out to discover that a thin thread of solidified metal was hanging from the nib. The nib was replaced by a capillary, and Czochralski verified that the crystallized metal was a single crystal. Czochralski's experiments produced single crystals a millimeter in diameter and up to 150 centimeters long. In 1950, the method was used to grow single germanium crystals, leading to its use in semiconductor production. 19