Why Signature-Fit

advertisement

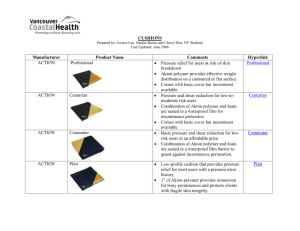

PRM Signature-Fit Seating Systems PRM Inc. 11861 East Main Rd. North East, PA 16428 www.prmrehab.com Order Options • Trial Fit – Rough shape sent with liner foam provides ability to trial shape and field modify • Cheese Cloth Trial Fit – Same as trial except includes disposable cloth covering to hold foam in place • Finish – Cushion is manufactured complete – Minor field modifications can be made with sewn removable covers only • VCO – Raw foam carving only Liner Foam • Liner Foam chosen will effect the support and feel of the cushion • Thinner, firmer foams will provide more positioning and support • Thicker softer foam will provide more forgiveness and pressure relief • ½ and ½, and ¼ and ½ liners provide the best option to have firm lateral control as well as pressure relief on the weight bearing area of client Liner Foam Con’t • Bottoming Out vs Not Sinking In – Foam works best when it allows for the client to sink in but not bottom out – If the client bottoms out then the cushion will not perform as required – If the client does not sink into the foam then the cushion will not perform as required • Medium vs Soft – The shape, size and soft tissue mass of the client will effect the best option – Error on the side of making the foam too firm or use foam combinations (½ soft on top and ½ medium on bottom) Junction Issues • Molded with a gap – Invacare has gap filled due to plaster – If gap is not accounted for when digitizing gap will be present • How to account for gap? – Measure distance between back of seat and bottom of back – Us digitizer to add to bottom of back cushion – Ask PRM to add back tongue, specify the length of tongue. If not specified will be 2” Junction Issues Con’t • No Gap – Make sure entire posterior pelvic wall of seat is digitized and pelvic control junction is checked on order form – Make sure digitizing starts at very bottom of back to maintain proper distance between back and seat • Specified Gap 1”, 2”, or 3” – Make sure to mark on order form gap distance – This will effect how we cut rear of seat and bottom back to obtain proper seat to back angles Reinforced Thin Laterals • PRM, Inc. reinforces lateral supports using 1/8” or 1/4” ABS plastic coming out to match the lateral depth. This provides an extremely solid lateral support. Pressure Relief Soft Spots • Pressure relief soft spots allow for weight bearing on safer surfaces • Foam layers are blended into the molded shape providing smooth transition between layers Vacuum Formed Vinyl • An excellent option for the institutional setting because it is the easiest to maintain. It can be wiped clean using soap and water but the vinyl does not stretch limiting the pressure relief capabilities of the cushion. Vacuum Formed Neoprene • Provides four way stretch maximizing the pressure relieving qualities of the cushion. Neoprene is incontinent proof and can be maintained by wiping the cushion with soap and water. Neoprene is not as durable as vinyl. Slip-On Removable Covers • Slip-On covers are available in Lycra®, Waterproof Lycra®, Polartech®, Dartex®, and Spacer Mesh. Due to the sewing of the fabric the covers are not incontinent proof. Even though the foam is protected with a polyurethane film incontinence barrier, we recommend a second removable cover for laundering purposes. • Minor field modifications can be done when using sewn covers Sewn Zippered Covers • Available in Neoprene®, Waterproof Lycra®, Polartech®, Dartex®, and Spacer Mesh, zipper covers provide increased pressure relief. Due to the sewing of the fabric the covers are not incontinent proof. Seams are sewn in areas where moisture is less likely to get into the cushion. A polyurethane film applied to protect the foam. Rail cuts, Footrest Removal Notches… • Signature-Fit has many options to assist in the interfacing of the cushion to the wheelchair. For a complete list of options and visual representation see our order form on-line or call us and request an order form. Lead-time • PRM will ship trial-fit and finished cushions within seven to ten working days. • You may doubt that we can really meet this ridiculously short lead-time, send us your order and we’ll prove it to you. Our Remake Policy • The Signature-Fit carving process allows PRM to ship unfinished cushions to you for “trial fit”, providing the opportunity to make changes to the shape prior to finishing the cushion. If you are extremely confident no modifications will be required you can bypass the trial-fit process and have the cushions finished. The lead-time remains at seven to ten working days even if you by-pass the trial-fit step. Why Signature-Fit? • Cushion Performance • Lead-time – Signature-Fit cushions utilize – 7 to 10 business days both firm and soft foam to for finished cushions provide the support your • Trial Fit Policy clients require and the soft feel – Trial fit the cushions for they demand difficult clients, to be • Functionality of product sure the cushions will – We can fabricate custom provide the support cushions to meet your required specifications • Customer Service – Data is easily captured and e– Custom seating is all mailed to streamline the order we manufacture process Finished Cushion • Signature-Fit cushions provide the support your clients require using the firm foam and the soft feel they want using the soft foam. The foam combination maximizes the pressure relieving qualities of the cushion shape.