setupprj4

advertisement

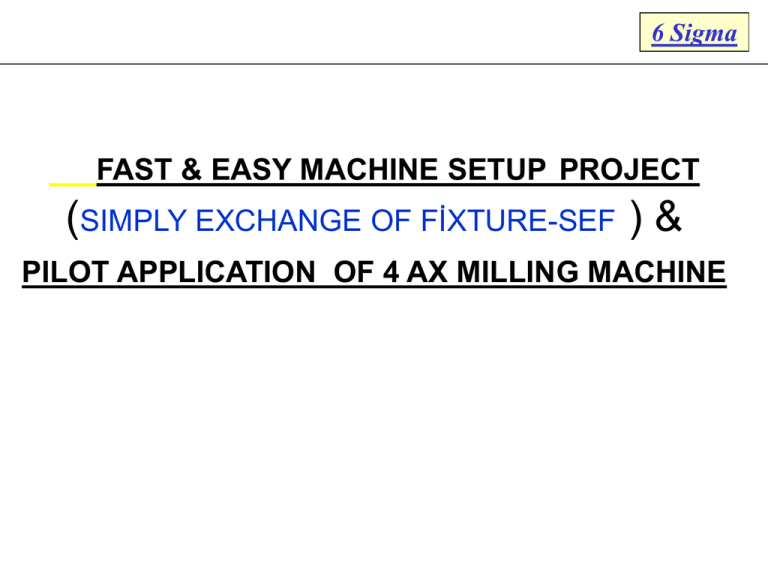

6 Sigma FAST & EASY MACHINE SETUP PROJECT (SIMPLY EXCHANGE OF FİXTURE-SEF ) & PILOT APPLICATION OF 4 AX MILLING MACHINE Mümtaz ERDEM PROJECT SUMMARY 6 Sigma Project Y - PRODUCTION Project Description SEF-Simply Exchange of Fixture and Pilot Application on 4 Axis Machine Project Objectives/Goals Production Flexibility and Decrease Setup Time Customer/GE Benefits •Reduced cycle time/improve capacity Financial Benefits Y Owner MBB/BB Project Title: Create an order to get tool, Project ID#: - Six Sigma Project Status fixture, gage, and cnc program in digitam system Status as of: Measure-Analyze Expected Completion Date: Project Leader: Y Owner: Project Y: PRODUCTIVITY Financial Benefits: Project Statement & Benefits MMEASURE ANALYZE Scope: • Goals & Objectives: Flexibility on production Decrease Setup Times • Benefits: Reduced cycle time / Improve capacity Status • • • Accomplishments: Data gathering, fixture and Machine Tools applied: Significant findings: CONTROL Team Members Name • IMPROVE Function BLACK BELT BLACK BELT SUPR.TOOL GREENBELT GREENBELT SUPERVISOR . SUPERVISOR TOOL STOCKKEEPER 12345678- Next Steps • Next steps: • • Additional tool to be applied: Design system & Help needed: Yes CTQ’s - Defect - Target 6 Sigma CTQ HIGH SET-UP TIME, NONFLEXIBLE SETUP Defect STANDARDISATION Target 25% DECREASE OF S/U TIME & MORE FLEXIBILITY 6 Sigma 4 AXIS / 36" PART NO OP. NO SET-UPRUN TIME N FIX NO MOUNT RING 1364M37G02 65 - 70 1,8 33.21 1 M91554 1364M37G02T 196 1 2 MID GUTTER 1807M62P01 10 1,3 1,91 2 TEI 2764 FORWARD RING1964M52P05 130 1 1,39 3 M93015 LOWER BEAM 9348M61P01 3 0 2,35 4 TEI 1964 115 2 2,03 ACT.RING 9539M39G04 150 1,5 10,15 5 M91644 170 0,5 2,03 6 M91645 #7 BRG. HOUSINL14405P02 G 70 1,5 3,2 7 M91057 TORK SHAFT L44815G01 105 0,5 3,8 8 M92420 #4 BRG. HOUSIN9646M10P03 G 60 0,3 3,3 9 M91102 FİXTURE GEO. FIX.DIA. D 41"x 2.25 D D P 24" X 2.5" 38" X 1.5" exp. D D D P D 44" x 4 44 x 3" 28"X7" FIX DIM(aXb) ALT.MACH MCB1210/MC98 22"x7.5"x1" MCB1210/MC98 41 "x 10" x1.5 " 26"X8" TABLE-1 MACHINE-FİXTURE & OPERATION DATAS MCB1210/MC98 6 Sigma 80000 70000 60000 50000 40000 30000 20000 10000 0 1. qu ar te r OPTIME S/U TIME 6 Sigma OPERATION & S/U TIME RELATIONSHIP 35 30 25 20 OP S/U 15 10 5 0 M37 M52 M61 M39 L44815 CAUSE AND EFFECT 6 Sigma OPERATOR TRAINING SHIFT FASTENİNG MAT’L CARELESSNESS High S/U Hours STANDARDIZATION FLEXIBLE CHANGING FIXTURE CHIP CLEAN METHODS EQUIPMENT WHY 4 AXIS MACHINE b 6 Sigma •Capability of Holding up to 25” tools •Rotating Table & Machine Course •There is only one Milling Machine With this spesifications •Heavy & Large Fıxtures, • Because of small lot size Frequent Set-up Changıng, req. GENERAL VIEW OF THE 4 AX MILLING MACHINE 6 Sigma •Flexible Set-up Requırements, Geometric Differencies of the Fixtures •Group Technology Appl. diffuculties DIFFERENT VIEWS FOR 4 AX MACHINE 6 Sigma •Due to 4 Axıs Milling Machıne Applıcatıon Results Wıll be Affected of Other Vertical-Horizontal and Multiple Axis Milling Machine Flexıbılıty Studıes... For This Reason ; 4 axis Milling Machine were Selected to the Pilot Applicatıon. FLOWCHART FOR SETUP Fixture Handling from SRS Fixture Cleaning To the Machine Machine Placement Internal S/U Fixture Fastening Part Handling Part positioning External S/U 6 Sigma T nut, Fastener Finding Setup Control 6 Sigma • WHY THE TIME IS INCREASING? • • • • • • Dimensions and weights of the fixture Fix. Geometries haven’t standart Shapes Nonstandart Pın and Bolts slots & Holes Used Nonstandart Bolts Rotary Table Properties, Parts have different Datum Systems (Point ,area etc.)For this reason, there are very complex shape fixtures, • Expanding fixtures • T-Nut and Fastening Elements Problems - Look for elements, Time requıred Workıng Procedures •As a Basement of Work;Fixtures will be fastened on machine as little as possible, No need positıonıng •Fixtures and Machine datas are available; (Table-1) 6 Sigma •All Fixtures were layed out on Machine Rotary Table With Sub Plate. For this Reason Subplate Will be Designed & positioned with PinBushing systems & Fastened to the fixture with Bolt-Nut Workıng Procedures and troubles •Big Dimensions & Geometric Differencies and Datum Systems properties of Fixtures • will be Controlled on Real/Right places •Expanding Fixtures are some different Applications Requıred, •Due to Set up reduction time T-Nuts on the rotary table, works; -Bolts,Nuts Eye bolts 6 Sigma will be placed near of the Machine These type of problems are caused increasing for Setup Times. FIXTURES GENERAL VIEW OF FIXTURES 6 Sigma Workıng Procedures 6 Sigma • We are working on the; - Innovatıve and İmproved best Concepts Linear Bushing Systems • One of the most important and innovative Equıpment are researching for Cleaning on the Machine Rotary Table •Chips penetrated on the table, T-Nut channels, bolt holes and the other slots and holes. •İnnovative cleaning, New easy cleaning Facility and Equıpments or; •Chips may be holded without dropping These are researching for new innovation... ROTARY TABLE and FİXTURE LAYOUT ON THE TABLE 6 Sigma AL T - PL AKA 4 1" M3 7 F ix t . 4 4 " M3 9 f ix t . T ORK SHAF T F ix t L OWER BEAM F ix t . 3 6 " DÖNEL T ABL A ROTARY TABLE and 5 DIFFERENT PARTS FIXTURES ON THE TABLE M39 Fixturing & Sub Plate section View 6 Sigma M39 Fixture & Sub Plate Assy. AĞIRLIKLAR; FİKSTÜR;780 kg ALT TABLA; 289 kg. 6 Sigma General View for Sub Plate 6 Sigma General View of SubPlate GGG 60 6 Sigma LINEAR BUSHING SYSTEMS 6 Sigma 6 Sigma procedure • Machine datas, • • • Rotary table Course T NUT ChannelI • Fixturing Datas • • • Geometry & Dimensions Holes Fixturing systems (EXP, Datum systems etc.). • Define SEF systems • • • • Designing Subplate Pın-bushing Systems Selectıon Design Pin-Bushing position of subplate-Fix. Assy Define Positıon and Tolerances • Sub Plate properties • • • • Weight Sub plate Strength Calculatıon Pin-Bushing stress analysis Fixture Pin & Nut Stress Analysis • Sub Plate -Rotary Table Fastening Method. • • T-Nut Channels Sub plate/Rotary Table Assy Design 6 Sigma Materials 6 Sigma SubPlate Material: GGG 60 - Spheroidal Cast Iron Weight; 285 Kg. TOTAL Max Load on Rotary Table; 1070Kg. Important Issues 6 Sigma • Subplate Dimensions and Position Tolerances (.0000-.0015) • Pın-Bushing Application and Fixtures thickness Differencies,For this reason Pin-bushing Position, • If using linear Bushing Systems, Big and heavy Fixtures will be damaged on roller Bushing. For this reason radial and axial loads and stress will be defined. • Subplate -fixture fasteners like Bolt, Nut, Pin, eye bolt stress analysis required SAVING • • • • • • • • • • • • ALL PARTS HAVE 20 S/U /YEAR MİN %25 SAVING 30 HRS FOR M61 PARTS 20 HRS FOR M39 PARTS 20 HRS FOR M37 PARTS 20 HRS FOR M52 PARTS 16 HRS FOR L44815G01 PARTS TOTALLY 100 HRS/YEAR FOR 4 AXIS MACHINE 106*18=1908$ FLEXIBLE SETUP AND OPERATOR SAVING RELAX SETUP APPROX % 50 SAVING FOR POSITIONING; NO NEED USE CLAMP, T-NUT etc. 5$ *25=125$ • OPERATOR ASSURANCE, SAFETY AND EASY SETUP PROGRAM PLAN 6 Sigma PROGRAM PLAN FOR SETUP REDUCTION BB. : PLANNED REV : OI COMPLETED FW:6 1 SUBJECT OCAK ŞUBAT MART NİSAN MAYIS HA RESPONSIBLE 1 2 3 4 5 6 8 9 # # # # # # # # # # # # # # # 1- OPERASYON ,TEZGAH VE FİKSTÜR DATALARININ TESPİTİ, ÖLÇÜMLER,FİKSTÜRLERİN TEZGAH ÖNÜNDEDEĞERLENDİRİLMESİ 2-DELİKLERİN CIRCULAR EKSENLERİNİN TESPİTİNDEN SONRA BALL-LOCK ve/veya PİM İLE YERLEŞTİRME KARARI , TAŞIYICI ASKI SEÇİMİ . . . 3- FİKSTURDEKİ BAĞLAMA DELİKLERİNDEN HAREKETLE SUB- PLATE TASARIMI TEAM 4-SUBPLATE İMALATI (DÖKÜM VE İŞLEMESİ), PİM-BURÇ İMALATI) ve TEDARİĞİ TAKIM-KALIP 5-FİKSTÜRLER BELİRLENDİKTEN SONRA İŞLEM SIRASINA GÖRE DELİNMELERİ TK-KL/İMALAT VE BURÇ ÇAKILMASI YERLEŞTİRİLMESİ 6-FİKSTURLERİN SUBPLATE İLE DENENMESİ , CNC PROGRAMLARININ TADİLATI P P P P P P Six Sigma Project Scorecard Measure Understand Environment - Meet business leader - Establish key contacts - Tour process - Identify process owner - Identify team members Bound the Project Train Team on 6 sigma tools Create Product Tree Identify Customer Requirements - CTQ’s via QFD - Identify additional data Needs Create Process Map Coordinate with ITS for systems resources where applicable Define performance standards - Gather / Pareto data - Review Historical data Evaluate measurement system - Gage R&R Establish Product Capability - Calculate DPU - Calculate Z st and Zlt Develop Presentation - Review Team / MBB / Sponsor - Present results to Champions and Operational Leaders Analyze Improve 6 Sigma Control Review Measure Phase - Champion comments - Update team / stakeholders Review Analyze Phase - Champion comments - Update team / stakeholders Review Improve Phase - Champion comments - Update team / stakeholders Train Team on 6 sigma tools Train Team on 6 sigma tools Train Team on 6 sigma tools Define Performance Objective for “Y” Review process map Develop new process flow Process Map Identify Variation Sources Screen Potential Causes Identify Root Causes of variation Identify X’s - Cause & Effect Diagram Establish Operating Tolerances Issue Revised QCWIs / procedures where applicable 10% 20% Revalidate Cause & Effect of X’s to Achieve Y’s Determine Process Capability Implement Control System for Process Fixes 30% 40% Benchmark similar products and processes Identify Improvement Actions and Implementation Plan Analyze Data - Apply Statistical Tools - Hypothesis Tests Develop Risk Assessment Risk Abatement Plan Identify Opportunities for Standardization Obtain buy-in / support for improvement actions List Best Practices and Identify Lessons Learned 60% Implement Improvements Collect & analyze data to validate improvement Identify opportunities to leverage improvements 70% Define additional data needs Develop Presentation - Review Team / MBB / Sponsor - Present results to Champions and Operational Leaders Communicate Improvements Develop Presentation - Review Team / MBB / Sponsor - Present results to Champions and Operational Leaders Identify Follow-up Action Plan and Individuals Responsible 50% Hand off project to Process Owner Develop Presentation - Review Team / MBB / Sponsor - Present results to Champions and Operational Leaders 80% 90% Monitor process performance 100%