Cutting Process

advertisement

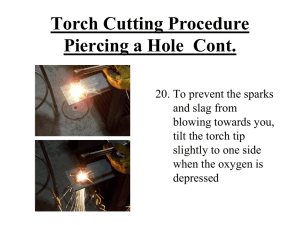

Cutting Operations Weld I – Ch. 33 Weld II – Ch. 4 Oxy-Acetylene Torch Cutting • Only Ferrous metals can be cut with a Oxy-Acetylene torch – Cutting is allowed because of oxidation (high speed rusting process) – The oxygen does the work • The cutting torch consists of two oxygen needle valves and oxygen pressure lever. There is only one acetylene valve. – Torch tips vary in size and use: The small holes on the outside of the tip are preheat holes, and the large one in the center is the cutting hole. • Oxy-Acetylene Torch Formula – Fe + O = FeO + Heat • Oxygen & Acetylene Regulator Pressure – Our shop for using the cutting torch (not gas welding) • Acetylene 2-3 psi Propylene: 4 psi • Oxygen 20 - 25 psi O2 with Propylene: 25 – 30 psi • Acetylene becomes unstable @ 15psi: max working pressure • Oxygen pressure may vary depending on the thickness of the metal to be cut. (under ½ inch) • Lighting the torch 1. 2. 3. Turn on the acetylene valve (1/2 turn) Cutting Demo Use striker to ignite flame If you are using a torch with two oxygen needle valves, open the first one at least 3 – 4 turns. Then use the second needle valve to adjust for a neutral flame. Then depress the oxygen lever and additional adjustment may be necessary with the secondary valve. Next slide • Cutting Steel – When beginning make a straight chalk-line to follow – With the torch having a neutral flame, hold the torch so that the oxygen pressure lever may be depressed with your thumb of your dominant hand. With your off hand, lay the torch neck across your hand to act as a guide as you cut. – To make a clean cut a person needs to be steady and consistent, this will be hard at first. – To start hold the flame vertical approximately 1/16” above the edge of the plate on the chalk-line or soapstone. Keep the torch in that position until the metal has been heated to a bright red state. • Cutting Steel Cont. – Gradually press down on the oxygen lever and move forward slowly along the line. The rate of travel should be just rapid enough to insure a continuous cut. • One way to make sure the cut is going all the way through the metal is a steady stream of sparks under the cutting table. – The line or groove left behind the torch is called the Kerf. – If the cut does not seem to be penetrating all the way through the metal, close the oxygen lever and reheat the metal again. – Sometimes slag will form at the bottom and keep the metal from falling, use a hammer to separate the two pieces. – When a straight cut is desired, clamp a straight edge along the cut line to act as a guide. * Is it possible to turn off the acetylene knob and continue a cut with only the oxygen lever open? • Cutting round-bar stock • Beveling • Cutting a circle or piercing a hole Cutting Demo – To cut a circle pierce a hole inside the circle. Hold the flame at a normal range, moving the torch in a circular motion & press the oxygen lever. Movement of the torch is very important to keep slag off of the torch tip. Next Slide • Torch cutting – A circle-cutting guide with a magnetic base • A mechanical torch (track torch) • Torch care and cleaning – Never use the torch as a hammer – Rub over a piece of wood to clean minor build-up • Doing this consistently upsets the instructor!!!! – Use a tip cleaner to file clogged holes • Remove the tip first – Inform the instructor if the tip appears bad • Cutting cast-iron with oxy-acetylene – Do not start the cut until you are sure you can complete it. – Regulator Pressure – Oxy – 40 psi Acet: - 7 psi: ½ “ or less cast – Flame: Carburizing flame, white cone should be same thickness as cast iron, adjust with oxygen lever open. • Cutting with Shielded Metal-Arc – Not as clean as a torch or other methods – Use electrodes such as E-6010 or E-6011 • The diameter of the electrode will depend on the thickness of the metal • The motion used will also depend on the thickness of the metal • Use when convenient and it is the only means available. Metal thickness larger than electrode Piecing Holes Thin sheet metal Cutting pipe or round stock • Cutting with Carbon Arc (Air Arc) – Special carbon electrode – Attach to air line with stinger attachment – Turn our arc welders on High output setting with the dial turned all the way up. – Strike like lighting a match • Not for precise cutting, lot of clean-up • Primarily used in demolition of junk cars, and heavy I-beams, heavy gauge metals, etc. • Used primarily when a torch is not accessible • Will be demonstrated in class • Plasma Cutting – – – – – Plasma is the fourth state of matter Cuts all types of metal: Aluminum, Stainless (non-ferrous-ferrous) Reaches temps 25,200º F Plasma produces -- “Latent Heat” (worksheet!!) Drawbacks • Consumable Parts • Noisy • Messy/ Toxins released/ Vent system – Benefits • Clean cuts • Any type of metal • Little clean-up on metal Review of Testing Gas Welded Joints • Lap joint – Bend the top piece of metal upright and bring it to about 90° perpendicular to the lower piece of metal. Use a chisel (tool room) to perform this test. Use the vice “outside” to hold the metal • T – joint – Bend the horizontal piece of metal towards towards the weld using the vice “outside”. • Flange joint – A flange joint can be visually tested and requires not filler rod with the weld. Applications • An optical pattern tracer with two torches • A cross section of a optical pattern tracer Safety Precautions • • • • • • • Always where eye protection!!!! Never use the torch as a hammer!!! Be aware of your surroundings Where will the metal fall? No combustible materials Appropriate clothing and eye protection Sparks on concrete floors cause the concrete to crack and shoot particles upward • Regulators are adjusted to the correct settings • Cutting apparatus is in appropriate condition Web Sites New torch technology Improved Torch Chapter Review Questions 1. What process causes metal to rust? 2. How does the cutting tip differ from the welding tip? 3. As a general rule, where should the cut be started? At the edge of the metal or in the middle? 4. How can a person tell a cut is going all the way through the plate? 5. What type of flame is used to cut cast iron? 6. Why is it important to inspect your surroundings before cutting a piece of metal? 7. What cutting process can cut any type of metal? 8. Before depressing the oxygen lever, the metal should be at what state? 9. To cut a piece of steel less than ½ inch thick, the regulator pressure should be _________ Acetylene, and _______ for oxygen. 10. What arc electrode may be used to cut metal? Answers 1. 2. 3. 4. 5. 6. Oxidation Preheat holes At the edge of the metal Sparks underneath the cut Carburizing Safety factors, oil & grease, another person standing close by, etc. 7. Plasma Cutter 8. Molten state, orange glow, etc 9. Acetylene 2-3 psi, O2= 20-24 psi 10. E-6010