Field Data Collection Methods

advertisement

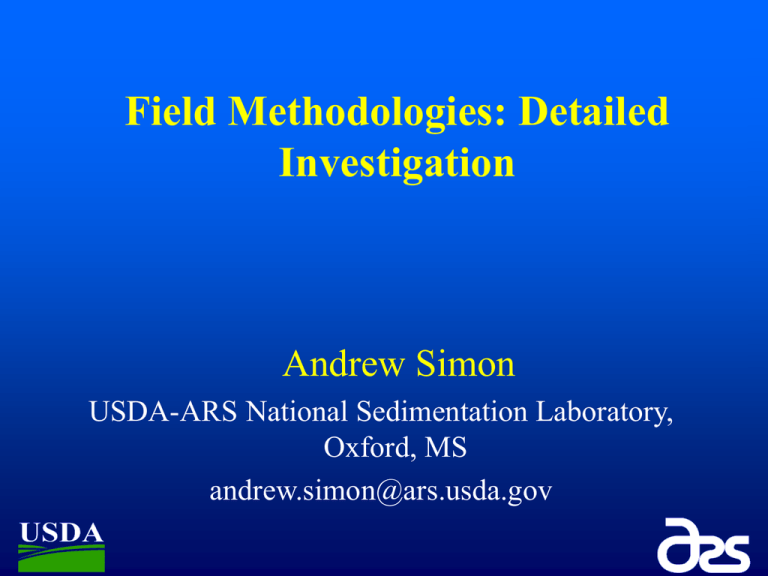

Field Methodologies: Detailed Investigation Andrew Simon USDA-ARS National Sedimentation Laboratory, Oxford, MS andrew.simon@ars.usda.gov Aims of this Section • To describe the methodologies and instruments used to collect the necessary data for bank-stability modeling. Fundamental Processes Behind Bank Stability If we want to predict bank stability we need to quantify the underlying processes controlled by force and resistance to mass failure and hydraulic shear: • • Bank shear strength (resistance to mass failure) vs. Gravitational forces Bank-toe erodibility (resistance to hydraulic erosion) vs. Boundary shear stress National Sedimentation Laboratory Bank Profile and Stratigraphy • Select critical bank geometry and survey profile to thalweg; • Notate bank stratigraphy (including bank toe dimensions and slope), dominant size class and layer thickness from bank face or during augering; sample each layer for particle-size distribution; • Determine what techniques will be required to determine critical shear stress and erodibility of the bank toe and other layers; Bank Shear Strength Measuring Soil Strength • • • • In-situ tests – Borehole shear test (BST) Torvane – cohesion and friction combined Shear vane (undrained clays only) Laboratory test – shear box and triaxial cell Iowa Borehole Shear Tester Soil Strength Testing 80 70 60 50 40 30 20 10 0 y = 0.684x + 0.5 0 10 20 30 40 50 60 70 Normal Stress (KPa) 80 90 Shear Stress at Failure (KPa) Shear Stress at Failure (KPa) Shear Strength Envelope - Sand c' = 0.5, ' = 34 degrees 100 Shear Strength Envelope - Clay c' = 12.5, ' = 16 degrees 110 50 y = 0.296x + 12.5 40 30 20 10 0 0 10 20 30 40 50 60 70 Normal Stress (KPa) 80 90 100 110 Some “Ball Park” Figures (based on more than 800 tests) Soil Type Statistic Gravel* Sand Loam Clay c' ca ' (kPa) (kPa) (degrees) - 0.0 36.0 g sat (kN/m3) 20.0 75th percentile 5.8 1.0 32.3 19.1 Median 2.9 0.4 30.3 18.5 25th percentile 1.3 0.0 25.7 17.9 75th percentile 11.9 8.3 29.9 19.2 Median 8.4 4.3 26.6 18.0 25th percentile 4.6 2.2 16.7 17.4 75th percentile 18.0 12.6 26.4 18.3 Median 11.0 8.2 21.1 17.7 7.2 3.7 11.4 16.9 25th percentile * From Selby (1982) Measuring Pore-Water Pressure • • Measure directly using tensiometers and piezometers Infer from water table height mw = h.gw. where mw = pore water pressure (kPa); h = head of water (m); gw = unit weight water (kN/m3) Measuring Matric Suction in the Field • Auger to desired depth for BST testing • Take undisturbed core with hammer sampler (take second core sample for bulk unit weight) • Insert digital tensionmeter •Record readings every 15 sec for 6 – 10 minutes Incorporating Suction in a Strength Test Unsaturated Shear Test, Goodwin Creek Bend, MS 75 70 Ca = 22.7 kPa ’ = 0.37 = 20.3o r2 = 0.99 Matric suction = 17kPa 65 SHEAR STRESS, IN kPa 60 55 50 45 40 Matric suction = 17kPa At b of 14° this gives; 17 x (tan 14 °) = 4.2 kPa added cohesion Therefore; 35 30 25 20 15 10 c’ = 22.7 – 4.2 = 18.5 kPa 5 0 0 10 20 30 40 50 60 70 NORMAL STRESS, IN kPa 80 90 100 110 Hydraulic Erosion Processes (Bank Toe) Hydraulic Erosion Processes • • • • Terms used in this section Hydraulic shear stress – the force exerted by water flowing over material, Pascals (1Pa=1N/m2) Boundary shear stress to, critical shear stress tc, excess shear stress te Erodibility – amount of erosion per unit excess shear stress, per unit time, m3/Pa/sec (m/sec) Erosion rate – rate of bank retreat, m/sec Shields Diagram by Particle Diameter (For Non-Cohesive Materials) Excludes cohesives Rule of Thumb for Uniform Sediments: tc (in Pa) = diameter (in mm) Erosion Rate and Excess Shear Stress: Cohesives e = k (to- tc) e = erosion rate (m/s) Obtained from jet-test k = erodibility coefficient (m3/N-s) device to = boundary shear stress (Pa) tc = critical shear stress (Pa) (to-tc) = excess shear stress Critical shear stress is the stress required to initiate erosion. Measuring Bank and Toe Erosion and Erodibility (Cohesives) • Jet test device scours a hole in the bank or toe and measures the shear stress and erosion rate • From this we calculate critical (threshold) shear stress and erodibility coefficient, k Measuring bank erodibility with the ARS non-vertical jet test device An Example: Test 2, Hungerford Brook, Rowell property, VT. 0.045 k (cm3N-1s-1) tc Shear Stress, Pa 0.040 Erosion rate (cm s-1) Erosion Rate, cm s-1 From Relation between Shear Stress and Erosion We Calculate tc and k 0.035 tc = 2.46 Pa 0.030 0.025 0.020 0.015 0.010 0.005 0.000 0.00 1.00 2.00 3.00 Shear stress (Pa) 4.00 5.00 Original Relation for Erodibility (k) Erodibility, m3/N-s k = x tc y = 0.2 tc -0.5 Where; tc = critical shear stress (Pa), x, y = empirical constants 3 ERODIBILITY COEFFICIENT (k), IN cm /N-s 10 1 Hanson and Simon (2001) 0.1 0.01 k = 0.09 tc -0.48 0.001 0.0001 0.01 0.1 1 10 CRITICAL SHEAR STRESS, IN Pa 100 1000 Distributions: Critical Shear Stress 100 90 80 PERCENTILE 70 60 Yalobusha River System Kalamazoo River James Creek Shades Creek Missouri River Upper Truckee River W. Iowa, E. Nebraska N Fork Broad River Tualatin River System Tombigbee River S Branch Buffalo River All Data 50 40 30 20 10 0 0.1 1.0 10.0 CRITICAL SHEAR STRESS (Pa) 100.0 1000.0 Distributions: Erodibility Coefficient 100 90 80 PERCENTILE 70 60 50 Yalobusha River System Kalamazoo River James Creek Shades Creek Missouri River Upper Truckee River W. Iowa, E. Nebraska N Fork Broad River Tualatin River System Tombigbee River S Branch Buffalo River All Data 40 30 20 10 0 0.001 0.010 0.100 1.000 ERODIBILITY COEFFICIENT (k) 10.000 100.000 Erodibility Relation: Yalobusha River System, MS 1.E+02 y = 0.2447x-0.5898 R2 = 0.4394 ERODIBILITY COEFFICIENT (k) 1.E+01 1.E+00 1.E-01 1.E-02 1.E-03 1.E-04 1.E-07 1.E-06 1.E-05 1.E-04 1.E-03 1.E-02 1.E-01 CRITICAL SHEAR STRESS (Pa) 1.E+00 1.E+01 1.E+02 1.E+03 Erodibility Relation, Kalamazoo River, MI 100.00 -0.6096 y = 2.7075x 2 R = 0.5313 ERODIBILITY COEFFICIENT (k) 10.00 1.00 0.10 0.01 0.01 0.10 1.00 CRITICAL SHEAR STRESS (Pa) 10.00 100.00 Erodibility Relation: Shades Creek, AL 100 ERODIBILITY COEFFICIENT (k) 10 y = 5.011x-1.0463 R2 = 0.7122 1 0.1 0.01 0.001 0.01 0.1 1 10 CRITICAL SHEAR STRESS (Pa) 100 1000 Erodibility Relation: James Creek, MS 1.E+02 ERODIBILITY COEFFICIENT (k) 1.E+01 y = 1.0988x-0.5584 R2 = 0.4687 1.E+00 1.E-01 1.E-02 1.E-03 1.E-06 1.E-05 1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 CRITICAL SHEAR STRESS (Pa) 1.E+01 1.E+02 1.E+03 Revised Erodibility Relation 1000.000 -0.8375 y = 1.61 x r2 = 0.55 3 ERODIBILITY COEFFICIENT, IN (cm /N-s) 100.000 10.000 1.000 0.100 0.010 0.001 0.000 1.E-07 1.E-06 1.E-05 1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 CRITICAL SHEAR STRESS, IN (Pa) 1.E+01 1.E+02 1.E+03 Cohesive Strength Meter (CSM) The CSM consists of a water-filled chamber 30 mm in diameter that is pushed into the sediment. The jet of water comes from a downward directed nozzle in the chamber. The velocity of the jet is increased systematically through each experiment. Bed erosion is inferred from the drop in the transmission of infrared light across the chamber caused by the suspension of sediment. Example CSM Results 110 100 TRANSMISSION, IN PERCENT 90 80 70 60 50 40 30 20 tc = 11 Pa 10 0 0.0 10.0 20.0 30.0 40.0 50.0 SHEAR STRESS, IN Pa 60.0 70.0 80.0 90.0 Comparison of Methods: tc 100 PERCENTILE 80 Original Jet "Mini" Jet Cohesive Strength Meter 60 40 20 0 0.0001 0.001 0.01 0.1 1 10 CRITICAL SHEAR STRESS, IN PASCALS 100 Comparison of Methods: k 100100 90 80 80 60 60 PERCENTILE PERCENTILE 70 Original Jet "Mini" Jet Large jet Mini jet 50 40 40 30 20 20 10 0 0 0.01 0.01 0.10 0.1 1.00 1 ERODIBILITY COEFFICIENT (k) 10.00 10 ERODIBILITY COEFFICIENT, IN cm3/N-s 100.00