Safety Officer

advertisement

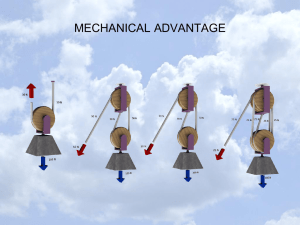

RIGGING OVERVIEW Updated Aug 7, 2013 Highline Overview 1. Highline Types 2. Components of the Kootenay Highline System 3. Highline Setup 4. Operation Highline Types Horizontal Highline Sloping Highline Drooping Highline Highline Setup Messenger Line Components of the Kootenay Highline System Anchors Pre-tension Back-tie Kootenay Pulley Track-lines Tag-lines Reeving-line Raising Systems Lowering systems Tag line Hangers High Points Tensioning System Components of the Kootenay Highline System Anchors Components of the Kootenay Highline System Anchors Components of the Kootenay Highline System Pre-tensioned Back-tie Anchor Systems Components of the Kootenay Highline System Kootenay Pulley Components of the Kootenay Highline System Track-lines Components of the Kootenay Highline System Tag-lines Components of the Kootenay Highline System Reeving-line English Reeve Components of the Kootenay Highline System Norwegian Reeving-lines Components of the Kootenay Highline System English Reeving-lines Components of the Kootenay Highline System Raising and Lowering Systems Components of the Kootenay Highline System Tag line Hangers (Festoons) Components of the Kootenay Highline System High Points Components of the Kootenay Highline System Tensioning System Components of the Kootenay Highline System Tensioning System Components of the Kootenay Highline System Tensioning System Highline Setup Safety Issues Messenger Line Pre-tensioning Tensioning Using Mechanical advantage systems Highline Setup Safety Issues PPE Edge safety Pay attention Listen No horsing around Highline Setup Pre-tensioning 6:1 Places initial tension in the system Highline Setup Tensioning 18:1 Rule – 1/2” Rope 12:1 Rule – 7/16” Rope Highline Setup Using Mechanical Advantage Systems Operation Commands Lowering Raising Reeving HIGHLINE RESCUE SYSTEMS Highline Rescue System Overview Components of a highline rescue team • Lowering belay system • Raising belay system • Reversing the system • Tensioning the system HIGHLINE RESCUE TEAM HIGHLINE RESCUE TEAM • Team Leader • Safety Officer • Edge Tender • Control/Operations • Static Anchor Team • Tag Line Team • Reeving Line Team • Medical/Attendant Team Leader • • • • Identify highline location Briefing and outlining objectives Identify anchors with squad leaders Give assignments SAFETY OFFICER SAFETY OFFICER • Rescue situations rapidly change. The effective Safety Officer must be able to forecast potential safety issues. SAFETY OFFICER • The Safety Officer is responsible for monitoring and assessing the safety aspects of all team operations, door-to-door. SAFETY OFFICER • A team Safety Officer should be assigned to every rescue mission and training event. SAFETY OFFICER • Any member of the team can call a STOP to an operation if a safety concern is detected SAFETY OFFICER 1. Scene Safety – Establishes, and marks a minimum 6’ safety zone at the edge – All personnel must be on a tether beyond this safety zone SAFETY OFFICER 1. Scene Safety – Determine if the rigging location is safe • Loose rocks • Unstable overhang • Awareness environmental safety issues – Poison Oak – Hornet’s nest – Requirements for Personal Floatation Devices SAFETY OFFICER 1. Scene Safety – – Checks each member’s minimum PPE • Helmet • Gloves • Harness Establishes a Safe Zone 6’ from edge SAFETY OFFICER 1. Scene Safety – Responsible for selecting safe helicopter landing zone. – Assures an emergency medical plan is in place – Assures Horseplay does not occur SAFETY OFFICER 2. System Safety – Checks each Anchor • Proper anchor materials • Proper anchor for situation • Bomb-proof anchor system • Angles SAFETY OFFICER 2. System Safety – Checks each system to the component level • Knots • Proper carabiners in use • Carabiners locked • Proper and adequate edge protection in place SAFETY OFFICER 2. System Safety – Checks each System • Adequate MA • Proper overall setup • Proper equipment used SAFETY OFFICER 3. Edge Tender Safety – Edge tender has independent anchor – Edge tender is tethered before approaching the edge SAFETY OFFICER 4. Operation Safety – Assures change-over procedures are conducted in a safe manner. – Assures adequate medical resources are considered when making search team assignments. SAFETY OFFICER 4. Operation Safety – Monitors the entire operation. – The Safety Officer can stop the operation at any time. – Monitor vehicle safety: sleepiness and adequate breaks on convoys. EDGE TENDER EDGE TENDER 1. Edge Tender Safety – Edge tender has independent anchor (may share a bomber anchor point, but may not attach to system anchors) – Edge tender is tied into an adjustable tether before approaching the edge – Clears loose rocks and tripping hazards from the edge EDGE TENDER 2. System Safety – Places ropes on appropriate edge protection – Assures ropes remain on edge protection. EDGE TENDER 1. Attendant Safety – Assist attendant and stokes over the edge EDGE TENDER 1. Attendant Safety – Weighting the system before going over the edge removes slack and stretch in the main line. 20’ of rope in operation, with a 2% stretch, will result in 3”-6” of sudden movement if system is not weighted. • • • Tightening of knots Stretch of rope Rigging extension EDGE TENDER – As attendant goes over the edge, the “Lower slow” used in approaching the edge should be slowed even more, – The attendant is rotating on a fixed point, neither moving back nor moving down. EDGE TENDER – Communicates with, and for, the attendant at the edge. – Halts system 1 meter from edge Edge Tender “STOP!” Ops Leader “Why Stop?” “Attendant tension the system” <attendant weights system> “Lower slow” “Lowering slow” “Attendant at the edge” <attendant rotates over edge> “Lower slow” EDGE TENDER – Provides voice communication between Ops Leader and Attendant to relay changes in speed control – Observes the path of the rope to detect additional rope hazards requiring edge pro Control/Operations Officer • Once all systems are built and safety checked. Team Leader gives control over to Ops Officer • Ops officer in charge of communication and operations of all systems Static Anchor Team • Navigating to position can be challenging • Determine static anchor/pre tensioned back tie • High directional • Tag line system, raising and lowering • Install tag line hangers Reeving Line Team • • • • Determine anchor Determine high directional Set up system Operate system, raising and lower Medical officer • First contact with subject • Independent rappel line to subject • While highline is being built medical officer will attend to subject, if access is available ADJUSTABLE EDGE TENDER LEASH • 8 mm Accessory cord – Attached to independent anchor – Attached to harness with Figure-8 on a bight and locking carabiner • 6 mm prusik cord – Attached to 8mm cord with prusik – Attached to harness with Figure-8 on a bight and locking carabiner HIGHLINE RESCUE SYSTEMS LOWERING/BELAY SYSTEMS SINGLE PRUSIK LOWERING BELAY RAISING SYSTEMS TANDEM PRUSIK RAISING BELAY RAISING SYSTEMS • Hauling without the aid of a system is a Mechanical Advantage of 1:1 • Also known as the Armstrong Method RAISING SYSTEMS • Our simplest system is the Simple 2:1 Mechanical Advantage • Components are: – Rope – One pulley RAISING SYSTEMS • Our basic haul system is the simple 3:1 Mechanical Advantage • Components are: – Rope – Two (2) pulleys – One (1) rope grab RAISING SYSTEMS • With the addition of a single pulley, the 3:1 is converted to a 5:1Mechanical Advantage • Components are: – Rope – Four (4) pulleys RAISING SYSTEMS • Piggybacking the simple 2:1 onto the simple 3:1 provides a compound 6:1Mechanical Advantage RAISING SYSTEMS • Piggybacking the simple 2:1 onto the simple 5:1 provides a compound 10:1Mechanical Advantage REVERSING THE SYSTEMS REVERSING THE SYSTEMS • Work on only one line at a time • Change the Main Line first, then the Belay Line • Wait for direction from the Ops Leader before you do anything. • Don’t anticipate a change to the system REVERSING THE SYSTEMS • Communicate – Tell the Ops Leader what you are doing, before you do it REVERSING LOWER TO RAISE • Step 1 – Assure you have the equipment you will need • One Pulley • One Progress Capture Device (PCD) REVERSING LOWER TO RAISE • Step 2 – Lock off your lowering device REVERSING THE SYSTEMS • Step 2 – Attach your Progress Capture Device (PCD) REVERSING LOWER TO RAISE • Step 3 – Unlock the lowering device and load the PCD • Step 4 – Attach the pulley to the LRH and rig the pulley REVERSING LOWER TO RAISE • Step 5 – Assemble your Haul pulley onto the running end of the rope • Step6 – Assemble your Rope Grab Device REVERSING LOWER TO RAISE • Step 5 – Attach your Rope Grab Device • Advise Ops Leader, “Main Line Ready to Haul!” REVERSING RAISE TO LOWER • Step 1 – Assure you have the additional equipment you will need • One Brake Bar Rack REVERSING RAISE TO LOWER • Step 2 – Remove the pulley and Rope grab and attach to the anchor plate -- Lower the Load onto the Progress Capture Device (PCD) REVERSING RAISE TO LOWER • Step 3 – Load the lowering device and lock it off • Step 4 – Use the Load Release Hitch to transfer the load to the lowering device REVERSING RAISE TO LOWER • Step 5 – Remove the Progress Capture Device – Retie the LRH • Step 6 – Prepare to Lower • Advise Ops Leader, “Main Line Ready to Lower!” TENSIONING SYSTEMS Forces on a Highline • When tensioning the highline it is important not to over tension the system • Need to stay within 10:1 SSSF (Static System Safety Factor) • The larger the angle at the mid-point of the highline, the more the load at the anchors is multiplied Tensioning Highline • Static System Safety Factor is a ratio between breaking strength of equipment and applied force (load) • Team standard is 10:1 • Using a rescue load (2kn), 10:1 sssf = 20kn • All equipment in system must have at least a 20kn rating • Why use 10:1 SSF • 10:1 sssf covers worst case scenario under a dynamic situation What is Worst Case Scenario ? • In a rescue situation Worst Case Scenario is when rescuer is transitioning over the edge. 2kn load Belay 1m 3m 1/3 Fall Factor 10kn to 15kn Peak Force Fall Amount of Rope BELAY COMPETENCE DROP TEST CRITERIA • British Columbia Council on Technical Rescue de facto standard Belay Competence Drop Test Criteria – 200 kg (440 lb) mass – 1 meter (3.28 feet) fall – 3 meters (9.84 feet) rope – < 1 meter (3.28 feet) arrest distance – Maximum 15 kN (3,375 lb) peak impact force This test also calls for the maximum force transmitted through the system to the anchor point to be no greater than 15 kN (3,375 lbf.) BELAY COMPETENCE DROP TEST CRITERIA • Edge Transition is the Worst Case Scenario – – – – – Slippage through the belay device Tightening of knots Stretch of rope Prussic extension Rigging extension Dynamic System Safety Factor • Peak force under WCS between 10 – 15 kn • Using a rescue load (2kn), 10:1 SSSF = 20kn • 10kn peak force/20kn breaking strength = 2:1 DSSF • 15kn peak force/20kn breaking strength = 1.5:1 DSSF • Both within 10:SSSF • Using the Average Dynamic Force formula Peak force = 12kn Dynamic System Safety Factor 20kn 15kn peak force 1.5:1 dssf 10kn peak force 2:1 dssf 10:1 sssf 2kn load • When tensioning the highline it is important not to over tension the system and stay within the 10:1 sssf – Using ½ inch rope rated at 40kn – 10:1 sssf = Max. 4kn load on anchor – Using 7/16 inch rope rated at 30kn – 10:1 sssf = Max. 3kn load on anchor Tensioning Rules • • • • One man rule Ten % rule Fifteen degree rule Number of persons rule Number of Persons Rule • Pull testing using dynamometers determined with ½” rope total mechanical advantage needed to stay within 10:1 sssf is 18:1 • 7/16” rope 12:1 mechanical advantage needed Standard Tensioning System • Compound 6:1, 3:1 acting on a 2:1 in series. • Need 18:1, total 3 people Standard Tensioning System • All anchor points can be on one anchor • BFT Pre Tension • Pre tension before loading the system • One person pulling hand over hand with 6:1 • No heave ho Tensioning • When highline is fully loaded 3 people hand over hand • No heave ho • If rescue load, system not loaded until subject and rescuer are on system MECHANICAL ADVANTAGE MECHANICAL ADVANTAGE • Forces we encounter in SAR • Simple Machines • Mechanical Advantage of Pulley Systems • Training Objectives – Participants will understand: • The Forces we encounter in SAR MECHANICAL ADVANTAGE • FORCE – What is Force – What types of Force do we encounter – What are the Units of Force MECHANICAL ADVANTAGE • What is Force? – Force is an external influence that may cause a body to accelerate. It may be experienced as a lift, a push, or a pull. – Force is a vector. All forces will have a magnitude and direction. • Forces we encounter in SAR – Forces due to: • • • • Gravity Friction Impulse Applied Forces • Gravity • g = 32.2 ft/sec2 = 9.8 m/s2 • F = ma • F ≈ 0.10197 kg x 9.8 m/s2 = 1Newton (N) • A newton is the amount of force required to accelerate a body with a mass of one kilogram at a rate of one meter per second squared. • 1 kN = 1,000 N ≈ 224.81 lbf • Gravity = Weight – 1 kN = 224.81 lbf – 80kg (0.8 kN ≈ 1 kN) for a ‘single load’, – 200kg (440 lbs = 1.95 kN ≈ 2 kN) for a ‘rescue load’ – 280kg (617 lbs = 2.7 kN ≈ 3 kN) for a ‘three-man load’. • Gravity = Weight – 1 kN = 224.81 lbf – 1 Person ≈ 1 kN – 2 Person ≈ 2 kN – 3 Person ≈ 3 kN • Gravity = Weight – The average rescuer can hold or apply a .2 kN force with one hand (≈ 45 lbs) – The average rescuer can hold or apply a .4 kN force with two hands (≈ 90 lbs) – Hauling an rope ‘hand-over-hand’ is applying a force of 45-50 lbs • Impulse • Reaction time to a failure or rope movement is 1 sec • In 1 sec a load will travel 16 feet MECHANICAL ADVANTAGE • Simple Machines MECHANICAL ADVANTAGE • Machines are affected by factors such as friction and elasticity • So the actual mechanical advantage of a simple machine will usually differ from its theoretical value. MECHANICAL ADVANTAGE Pulley: • Pulleys change the direction of a tension force on a flexible material, e.g. a rope or cable. In addition, pulleys can be "added together" to create mechanical advantage, by having the flexible material looped over several pulleys in turn. More loops and pulleys increases the mechanical advantage. MECHANICAL ADVANTAGE Pulley as a Lever: • The pulley is a variation of the wheel and axle. • The size of a pulley does not influence the MA. • The size of a pulley does influence the efficiency of the pulley. • The larger the pulley, the more efficient the pulley. MECHANICAL ADVANTAGE Pulley Types: • Fixed pulley – Provides change of direction ONLY MECHANICAL ADVANTAGE Pulley Types: • Movable pulley – Adds Mechanical Advantage MECHANICAL ADVANTAGE Pulley: • Pulleys change the direction of a tension force on a flexible material, e.g. a rope or cable. • Pulleys can be "added together" to create mechanical advantage, by having the flexible material looped over several pulleys in turn. • More loops and pulleys can increase the mechanical advantage. MECHANICAL ADVANTAGE Pulley Efficiency: • Two factors determine a pulley's efficiency: – Sheave size: the large the sheave diameter, the higher the efficiency. – Bushings and bearings: self-lubricating bushings are efficient, but they must be regularly maintained. Ball bearings are very efficient and since they are sealed, they do not require any maintenance. MECHANICAL ADVANTAGE • Effective pulley systems must always have one side anchored and the other side attached to the moving load, known as the anchor side and the load side. There must be something to pull against MECHANICAL ADVANTAGE • The longest distance a pulley system can be stretched, the distance from the anchored pulley to the moving pulley, is called the stroke. • The longer the stroke, the more useful the MA system. MECHANICAL ADVANTAGE • Pulling the system down to its smallest stroke is called compression. • It is called de-set when the system is compressed so it will expand again when using the MA system as the Decent Control Device (DCD) to lower a load rather than to raise it. MECHANICAL ADVANTAGE • Extension means to pull out a pulley system to its longest stroke. Re-set in when the system is extended again during raising operations and another haul segment is made on the main line. MECHANICAL ADVANTAGE • All anchored pulleys are Change Of Direction (COD) only. MECHANICAL ADVANTAGE • Pulleys that move with a load (unanchored pulleys) are simple machines that gain advantage. MECHANICAL ADVANTAGE • Pulley systems are either simple, compound or complex. • Compound pulley systems are made up of at least two simple pulley systems. • Complex pulley systems are made up of at least one simple pulley system and at least one compound pulley system. MECHANICAL ADVANTAGE • If the terminal end of a haul line is attached to the anchor, the simple pulley system will be EVEN • 2:1, 4:1, 6:1, 248:1 MECHANICAL ADVANTAGE • If the terminal end of a haul line is attached to the anchor, the simple pulley system will be EVEN • 1:1, 3:1, 5:1, 115:1 MECHANICAL ADVANTAGE • Simple pulley systems have a greater stroke than compound pulley systems of the same MA. MECHANICAL ADVANTAGE • Mechanical Advantage MECHANICAL ADVANTAGE • The Mechanical Advantage of a pulley system can be expressed as a ratio. • It is the ratio of the amount of force that must be applied to a haul line to move a load, divided by the weight of the object that must be moved. • It is the ratio of the weight of the object that must be moved to the amount of force that must be applied to move it. • 2:1 = 2 Units of output force will result from 1 Unit of input force • Tomorrow 07:30 • 24 hour packs – – – – – – – Helmet Harness Gloves Orange Shirts / Green pants Lunch Water Rain Gear DEMO & HANDS ON PRACTICE