File

advertisement

TRANSPORTATION ENGINEERING-II

AASHTO 1993

Flexible Pavement Design Equation

AASHTO DESIGN

METHOD

• The basic objective of this test was to

determine significant relationship

between the no. of repetition of

specified axle loads (of different

magnitude and arrangement) and the

performance of different thickness of

pavement layers.

AASHTO DESIGN METHOD

CONSIDERATIONS

•

•

•

•

•

•

•

•

•

Pavement Performance

Traffic

Roadbed Soil

Materials of Construction

Environment

Drainage

Reliability

Life-Cycle Costs

Shoulder Design

STEPS FOR DESIGNING

• The AASHO design method states that:

• “The function of any road is to carry the

vehicular traffic safely and smoothly from one

place to another”.

• Following are the different steps

followed in AASHTO design method

while designing the pavement.

•

•

•

•

Measuring Standard Axle Load

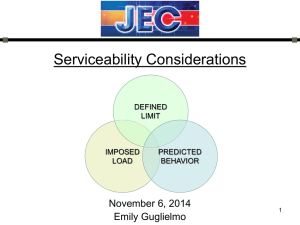

Predicting Serviceability

Performance

Present Serviceability Rating (PSR)

•

•

•

•

•

•

•

•

Present Serviceability Index

Terminal Serviceability

Regional Factor

Structural Number

Soil Support

Reliability

Over all Standard Deviation

Resilient Modulus

Standard Axle Load (ESAL’s)

• “An axle carrying a load of 18Kips and causing

a damaging effect of unity is known as

Standard Axle Load”.

Serviceability

• “Ability of a pavement to serve the traffic for

which it is designed”.

Performance

• “Ability of a pavement to serve the traffic for a

period of time”. Performance is interpreted as

trend of serviceability with time.

Present Serviceability Rating

• To define PSR, the AASHO

constituted a panel of drivers

belonging to different private

and commercial vehicles.

They were asked to

Very Good

Good

• Rate the serviceability of

different section on a scale of

0-5.

• Say whether the sections were

acceptable or not.

Fair

Poor

Very Poor

Present Serviceability Index (ISI)

• The prediction of PSR from these physical

measurements is known as PSI and defined as

“Ability of a pavement to serve the traffic for

which it is designed”. Normally the value is

taken as 4.

• PSI value depends on the following factors;

• Measurement of longitudinal surface irregularities

• Degree of cracking

• Depth of rutting in the wheel paths

Terminal Serviceability Index (ISI)

•

•

“The lowest serviceability that will be tolerated

on the road at the end of the traffic analysis

period before resurfacing or reconstruction is

warned”.

Its usual value is 2 for roads of lesser traffic

volume and 2.5 for major highways.

Basic design equation for Terminal Serviceability is

Pt= Gt-{log (Wt)-log (p)}

• =0.4+{0.081(L1+L2)3.23}/{(1+SN)5.19+L23.23}

• log (p)= 5.93 + 9.36log(SN+1)-4.79log (L1+L2)+

4.33log(L2)

• Gt=a logarithmic function of the ratio of the loss in

serviceability at time t to the potential loss taken to a point

where pt=1.50

• p=a function of design and load variables that denotes the

expected number of axle load applications to a pt=1.5

• = a function of design and load variables that influence

the shape of the p Vs W serviceability curve.

• Wt=axle load applications at the end of the time t

• L1=load on one single axle or on one tendon axle set, in

kg

• SN= Structural Number of pavement

• Regional factor

It is a factor which helps the use of the

basic equations in a climatic condition

other than the ones prevailing during

the road test. Its values are:

• Road bed material frozen to a depth of 5 in

or more (winter)

• Road bed material dry (Summer and fall)

• Road bed material wet (spring thaw)

• Structural Number

An index number that represents the overall

pavement system structural requirements

needed to sustain the design traffic loading for

the design period. Analytically, the SN is given

by:

SN=a1D1M1+a2D2M2+a3D3M3

Where

• D1,D2,D3 = thickness in inches respectively of

surfacing, base and sub-base.

• a1,a2,a3 = coefficients of relative strength.

a1

=

a2

=

a3

=

M1, M2,M3 =

M1

=

0.2 for road bricks

0.44 for plant mix

0.45 for the sand asphalt

0.07 for sandy gravel

0.14 for crushed stone

0.11 for sandy gravel

0.50 to 0.10 for sandy soil

drainage coefficients

1 shows good drainage conditions

Soil Support

• Its value depends on the CBR value of the

layer.

Reliability

It is defined as “probability that serviceability will be

maintained at adequate levels from a user point of view,

through out the design life of the facility”

• Overall Standard Deviation

It takes in to account the designer’s ability to estimate the

variation in 18K Equivalent Standard Axle Load.

• Resilient Modulus

It is defined as

Mr = Repeated Axial Stress / Total Recoverable Axial

Strain

Mr=CBR x 1500

AASHTO DESIGN

EQUATION

This equation is widely used and has the following

form:

Log10(W18)=Zr x So+ 9.36 x log10(SN + 1)0.20+(log10((ΔPSI)/(4.2-1.5))

/(0.4+(1094/(SN+1)5.19)+2.32x log10(MR)-8.07

where:

W18=predicted number of 80 KN (18,000 lb.) ESAL’s

ZR=standard normal deviate

So=combined standard error of the traffic prediction and

performance prediction

SN=Structural Number (an index that is

indicative of the total pavement thickness

required)

SN=a1D1M1 + a2D2m2 + a3D3m3+...

ai

=ith layer coefficient

di

=ith layer thickness (inches)

mi

=ith layer drainage coefficient

Δ PSI =difference between the initial design

serviceability index, po, and the design

terminal serviceability index, pt

MR =sub-grade resilient modulus (in psi)

Nomo-graph

1993 AASHTO Structural Design

Step-by-Step

Step 1: Traffic Calculation

Total ESALs

• Buses + Trucks

• 2.13 million + 1.33 million = 3.46 million

Step 2: Get MR Value

• CBR tests along Kailua Road show:

– CBR ≈ 8

• MR conversion

AASHTO Conversion

M R 1500CBR 15008 12,000 psi

NCHRP 1-37A Conversion

M R 2555CBR

0.64

25558

0.64

9,669 psi

Step 3: Choose Reliability

Arterial Road

• AASHTO Recommendations

Functional Classification

Recommended Reliability

Urban

Rural

WSDOT

85 – 99.9

85 – 99.9

95

Principal arterials

80 – 99

75 – 95

85

Collectors

80 – 95

75 – 95

75

Local

50 – 80

50 – 80

75

Interstate/freeways

Choose 85%

Step 3: Choose Reliability

Reliability

ZR

99.9

-3.090

99

-2.327

95

-1.645

90

-1.282

85

-1.037

80

-0.841

75

-0.674

70

-0.524

50

0

Choose S0 = 0.50

Step 4: Choose ΔPSI

Somewhat arbitrary

• Typical p0 = 4.5

• Typical pt = 1.5 to 3.0

• Typical ΔPSI = 3.0 down to 1.5

Step 5: Calculate Design

Decide on basic structure

Resilient Modulus (psi)

Layer

a

Typical

Chosen

HMA

0.44

500,000 at 70°F

500,000

ACB

0.44

500,000 at 70°F

500,000

UTB

0.13

20,000 to 30,000

25,000

Aggregate

0.13

20,000 to 30,000

25,000

Step 5: Calculate Design

Step 5: Calculate Design

Preliminary Results

• Total Required SN = 3.995

• HMA/ACB

• Required SN = 2.74

• Required depth = 6.5 inches

• UTB and aggregate

• Required SN = 1.13

• Required depth = 9 inches

Step 5: Calculate Design

Apply HDOT rules and common sense

• HMA/ACB

• Required depth = 6.5 inches

• 2.5 inches Mix IV (½ inch Superpave)

• 4 inches ACB (¾ inch Superpave)

• UTB and aggregate

• Required depth = 9 inches

• Minimum depths = 6 inches each

– 6 inches UTB

– 6 inches aggregate subbase

Comparison

Layer

California

AASHTO

HMA Surface

2.5 inches

2.5 inches

ACB

7.0 inches

4.0 inches

UTB

6.0 inches

6.0 inches

Aggregate subbase

6.0 inches

6.0 inches