Note - DOAS - Penn State University

advertisement

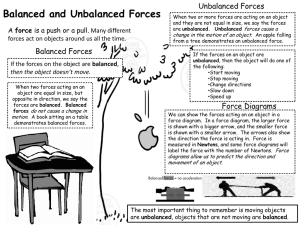

Dedicated Outdoor Air Systems (DOAS) and Building Pressurization ASHRAE Annual Conference Albuquerque Session 6 Monday June 28, 2010 Stanley A. Mumma, Ph.D., P.E. Prof. Emeritus, Architectural Engineering Penn State University, Univ. Park, PA sam11@psu.edu Web: http://doas-radiant.psu.edu 1 Presentation Outline Importance of building pressurization. Impact of TER on building pressurization. Estimating building pressurization needs. Ratio of pressurization air flow to total OA for various occupancy categories. Impact of unbalanced flow on TER performance in DOAS applications. New DOAS configuration? Research needs. Conclusions. 2 Is building pressurization important? Yes or no? Do you employ it? Why pressurize? – Limit moisture migration through the envelope, summer and winter? – Limit hot or cold locations around the perimeter—thermal comfort? How do you determine the required flow? 3 Source of pressurization air? Is the OA specified by Std. 62.1 sufficient? Is toilet exhaust part of the pressurization air requirement? Does the use to total energy recovery have any bearing on the issue of pressurization? 4 An example of a pressurized building without TER 5 Example of the same building with DOAS and TER Notice how the toilet exhaust is handled? Why, and how is it different than an all air system—even with heat recovery. The TER flow is unbalanced!! Does it 6 matter? DOAS Defined for This Presentation 20%-70% less OA, than VAV DOAS Unit w/ Energy Recovery Cool/Dry Supply Parallel Sensible Cooling System Building Pressurization High Induction Diffuser Building with Sensible and Latent Cooling Decoupled 7 How much air flow is required for building pressurization? Well, it depends--right? On What? – Building tightness. – Building use. – Construction quality. – Wind velocity and direction. – Stack effect. – Method of automatic control—if any. So how do you know what to design for? 8 How much infiltration would you expect if no pressurization— excluding toilet exhaust? Consider normal practice construction! It depends None ½ ACH 1 ACH > 3 ACH What is the basis for your opinion? Is ACH a floor area or wall area concept? 9 Published air tightness recommendations. ref: given in paper Note: Leakage is per unit area of exterior perimeter wall 10 Do we attempt to control a building pressure at 50 Pa? 249.1 Pa = 1” H2O. So 50 Pa = 0.2” H2O—clearly much higher than we attempt to pressurize buildings. Most buildings using pressurization differential control have 0.03” H2O, or 7.5 Pa. as the set point So the answer is no! Can we modify the published air leakage rates to reflect 7.5 Pa rather than 50? 11 Converting published 50 Pa leakage rates to 7.5 Pa. Applying the parabolic relationship: Bldg type Flow at Flow at 50 Pa 7.5 Pa School 0.4922 0.1902 Offices 0.2735 0.1507 Flow, cfm/ft2 wall area 12 Converting leakage rates at 7.5 Pa. from wall area to floor area. Assume 15,000 sq ft building with 10 ft high walls. Assume the length to width ratio is 2:1. Resulting wall area is 5,195 ft2 Leakage for office = 0.1057*5,195=549 cfm Converting to a floor area bases: 549/15,000=0.037 cfm/ft2 floor area (office) Similarly for school: Leakage is: 0.066 cfm/ft2 floor area. 13 Is there another place that OA is specified on a cfm/ft2 floor area basis? Is 0.037 and 0.066 cfm/ft2 floor area about the same order of magnitude as other floor area based sources? If expressed as an ACH, what would we get? Is it coincidence that the pressurization flow is of the same order of magnitude as the floor component of ASHRAE Std. 62.1? 14 TER unbalanced flow for different occupancy categories when the pressurization flow is ~1/2 ACH Does this surprise you? Have you observed, as I have, TER jobs returning only 30-40 % the flow expected? How bad is 30% to 70% of OA for pressurization? Note: floor frac = Pressurization fraction 15 Impact of unbalanced flow on TER performance For unbalanced flow, mOA= mRA + mPressurization hOA hSA Supply air Outdoor air m OA 0 scfm Purge or seal leakage Wheel Rotation Exhaust air hEA hRA Return air, including toilet mRA exhaust 16 Brief heat exchanger tutorial h, efficiency ? Circuit with min. m*Cp Tco if HTX infinitely 17 long Temperature profile for infinitely long HTX 18 Heat Exchanger effectiveness, e 19 For unbalanced flow, mOA= mRA + mPressurization hOA hSA Supply air Outdoor air m OA 0 scfm Purge or seal leakage Wheel Rotation Exhaust air hEA hRA Return air, including toilet mRA exhaust e = mOA(hOA-hSA)/mRA(hOA-hRA) = (hEA-hRA)/(hOA-hRA) eapparent = e*mRA/mOA = (hOA-hSA)/ (hOA-hRA) 20 100 1050 90 950 80 850 70 750 60 650 50 40 Recovered MBH based Recovered MBH upon an 85F 140 gr OA Eff. condition, an 75F 50% Eff RAApp. condition, and a 130” Dia EW (519 sfpm FV OA stream) 30 20,000 Balanced 18,000 16,000 Lecture Conf. rm 550 Recovered heat, MBH Eff and apparent eff Impact of unbalanced flow on EW performance: 20,000 scfm of OA 450 14,000 Educ. 12,000 Return air flow: scfm 10,000 8,000 350 6,000 Office 21 What does the need for pressurization and the negative impact of unbalanced flow on the TER performance Suggest? A new product. With fully integrated pressurization unit and a balanced flow DOAS. It might look like: 22 23 24 EW heat recovery performance cases 1050 Unbal F HR BFHR BF HR, 500 sfpm FV 950 130” Dia At summer design conditions Recovered Heat, MBH 850 750 124” Dia 130” Dia 117” Dia 650 130” Dia 112” Dia 550 450 350 250 20,000 72” Dia 18,000 16,000 14,000 12,000 Air Flow, scfm 10,000 8,000 6,000 25 Design and Off design heat recovery School 800 793 Design 750 713 700 669 Heat Recovery, MBH 650 1. 20000, 14000 85F 140 gr 130" wheel 2. 14000, 14000 85F 140 gr 130" wheel 3. 14000, 14000 85F 140 gr 112" wheel 600 550 500 450 4. 20000, 14000 75.45F, 90.25 gr 130" wheel 5. 14000, 14000 75.45F, 90.25 gr 130" wheel 6. 14000, 14000 75.45F, 90.25 gr 112" wheel 400 350 300 250 227 200 205 Off-Design 150 1 2 3 4 6 Cases, See details 5 192 6 26 First and Energy cost implications Cooling energy use increases a little. Fan energy use decreases due to EW flow resistance removal from the pressurization path. Net impact for 40o N. Latitude locations is annual energy use is about the same for an unbalanced flow unit and the integrated unit. 27 First and Energy cost implications About a $ 6/scfm first cost savings for air removed from the EW and processed through the pressurization unit. In the example of an office with an OA flow of 20,000 scfm, and a pressurization requirement of 14,000, the first cost savings amounts to about $84,000. Significantly, the low cost pressurization component is a good place to provide reserve capacity. Since about 20% reserve capacity is often provided, a 20,000 scfm OA requirement would provide another $24,000 first cost 28 savings! Important pressurization unit control point: Maintain a constant flow, rather than a DP! Assures balanced flow DOAS. Provides predictable basis for equipment sizing. 29 Advantages of integrated unit 1. Enables the first cost of the balanced flow DOAS to be reduced by nearly the fraction of pressurization flow. 2. Does not degrade the TER performance resulting from unbalanced flow 3. Allows reduced fan energy use since less combined supply air and purge air flow occurs on both sides of the wheel. Important since fan energy use is significant. 4. Allows lower operating cost, even though the cooling/dehumidification energy use may increase a little. 30 Advantages of integrated unit 5. Eliminates the added installation first cost for two systems (DOAS and Pressurization). 6. Allows energy use for pressurization to be limited with flow measurement control. 7. Allows reserve capacity to be added to the pressurization unit, at much lower first cost than in the DOAS where expensive heat recovery is used. 8. Simplifies controls by dividing the duties. 31 Disadvantages of integrated unit 1. May use more cooling energy. 2. Energy use results are sensitive to equipment selection, i.e. coil DP, fan h, TER selections (DP & effectiveness), air required for pressurization, cooling COP's. 3. May be falsely perceived as more complex. 4. Not very beneficial for unbalanced flows of less than 10%. 32 Research Needs Confirm the recommended limiting/ bounding flow rate for pressurization, i.e. 0.5 ACH (0.06 scfm/ft2 [0.3 L/s*m2]). Confirm that the recommendation to employ fixed measured pressurization flow control, with the occasional few hours of moisture migration through the envelope when infiltration may occur, does not lead to IAQ or comfort problems. Establish a systematic method for determining the appropriate reserve capacity. 33 Conclusions Building pressurization important Adequate pressurization is achieved with ~1/2 ACH, or about 0.06 cfm/ft2 floor area. Recommend an integrated balanced flow DOAS with a pressurization unit. Can provide huge first cost savings without an energy penalty. Now is the time for a new product!! 34 35