Fluid Mechanics

CHAPTER 5:

CONTROL VOLUME APPROACH

&

CONTINUITY PRINCIPLE

Dr . Ercan Kahya

Engineering Fluid Mechanics 8/E by Crowe, Elger, and Roberson

Copyright © 2005 by John Wiley & Sons, Inc. All rights reserved.

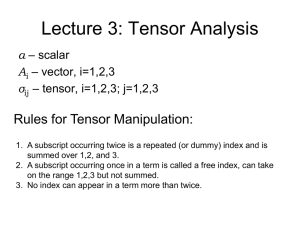

LAGRANGIAN & EULERIAN DESCRIPTIONS

Lagrangian Approach:

Describe the fluid particle’s motion with time.

The path of a particle:

r(t) = x(t) i + y(t) j + z(t) k

i, j, k: unit vectors

Velocity of a particle :

V(t) = dr(t) / dt = u i + v j + w k

Eulerian Approach:

Imagine an array of windows in the flow field: Have information for the

fluid particles passing each window for all time.

In this case, the velocity is function of the window position (x, y, z) and time.

u = f1 (x, y, z, t)

v = f 2 (x, y, z, t)

w = f 3 (x, y, z, t)

Eulerian approach is generally favored

CONTROL VOLUME APPROACH:

“Focusing on a volume in space & Considering the flow passing through

the volume”

* It derives from the Eulerian description of fluid motion.

* It involves transforming the governing equations for a given

mass (Lagrangian form) into the corresponding equations for

mass passing through a volume in space (Eulerian form)

• Mathematical equation needed for this transformation:

REYNOLDS TRANSPORT THEOREM

RATE OF FLOW

• Volumetric Flow Rate:

∆Volume in the figure:

= Length x Area = (V ∆t) x A

Q AV

Q = discharge [m3/s]

V = average velocity [m/s]

A = cross sectional area [m2

• Mass Flow Rate:

Mass of fluid passing a station per unit time [kg/s]

m mass flow rate m/t

ρ = density [kg/m3]

m AV Q

RATE OF FLOW: Generalized equation forms

Volumetric Flow Rate

Differential discharge:

dQ Vn dA

Using concept of dot product:

Vn dA V cosdA V .dA

Mass Flow Rate

Q V .dA

A

m V .dA

A

Mean Velocity

By definition:

_

Q

V

A

• In laminar flow, the mean velocity

is half the centerline velocity.

• In turbulent flow, velocity

profile is nearly flat so the mean

velocity is close to centerline

velocity.

REAL VELOCITY PROFILE:

• Parabolic for laminar flow

• Logarithmic for turbulent flow

Control Volume Approach

• FLUID SYSTEM: Continuous mass of fluid, containing always the same fluid

particles

– The mass of a system is constant

• CONTROL VOLUME (cv): Volume in space.

– It can deform with time

– It can move & rotate

– The mass of control volume can change with time

• CONTROL SURFACE (cs):

• Surface enclosing the control volume

• or boundary of control volume

Control Volume Approach

M sys (t ) M CV (t ) M in

M sys (t t ) M CV (t t ) M out

By definition, the mass of the system is constant, so

M CV (t ) M in M CV (t t ) M out

The rate form of Continuity Principle:

M CV M in M out

dM cv

min mout

dt

Example

• Considering a CV as shown in the earlier figure, a tank with crosssectional area of 10 m2 has an inflow of 7kg/s and an outflow of 5

kg/s. Find the rate at which the water level in the tank is changing.

The volume of CV: V = Ah

The mass in the CV: M cv = V = Ah

The rate of change of mass in the CV:

dM cv

dh

A

dt

dt

By the continuity equation, the rate of change of water elevation:

dh min mout

dt

A

= (7 - 5 ) / (1000 x10) = 0.0002 m/s

B (extensive property) of a system: proportional to the mass of the system (like m, mV, E)

b (intensive property) : independent of system mass and obtained by [B/mass]

Reynolds Transport Theorem

The most general form: (Read excellent explanations at pages 133-138)

dBsys

dt

b

b

B: extensive property

b: intensive property

t: time

ρ: density

V: volume

V: velocity vector

A: area vector

Left side is Lagrangian form & represents the rate of change of property B of

the system

Right side is Eulerian form & represents the rate change of property B in CV + the

net outflow of property B through the CS

This equation is often called “control volume equation”

Reynolds Transport Theorem: Simplified form

If the mass crossing the control surface occurs through a number of inlet and

outlet ports, and the velocity density and intensive property b are uniformly

distributed (constant) across each port; then

dBsys

dt

bdV bV. A

cv

cs

Please see the text book for the alternative form of the above equation

Continuity Equation

Derives from the conservation of mass which states the mass of the

system is constant in Lagrangian form. (M sys = const)

The Eulerian form is derived by applying Reynolds transport theorem.

In this case, extensive property: B cv = M sys

The corresponding intensive property: b = M sys / M sys = 1

Continuity Equation

Since dM sys / dt = 0

The general form of continuity equation:

=0

Accumulation rate Net outflow rate

of mass in CV

+ of mass through CS

If the mass crosses the control surface through a number of

inlet and exit ports, the continuity equation simplifies to

dM cv

cs min cs mout

dt

EXAMPLE 5.4:

Since there is only one inlet and exit port,

the continuity equation simplifies to

dM cv

min mout

dt

Mass flow rate in : ρ V A = 1000 x 7 x 0.0025 = 17.5 kg/s

Mass flow rate out: ρ Q = 1000 x 0.003 = 3 kg/s

Continuity equation:

dM cv

17.5 3 14.5kg / s

dt

Mass is accumulating in the tank at this rate!

EXAMPLE: (Problem 5.49)

Referring the figure below, find the velocity of the liquid through

the inlet. At a certain time, the surface level in the tank is 1 m and

rising at the rate of 0.1 cm/s.

Solution

Continuity Equation for Flow in a Pipe

Steady Flow

- CV is fixed to pipe walls

- Volume of CV is const.

- Mcv = const.

min mout

22 A22V22 11 A11V11

Continuity Equation

Q2 Q1

A2V2 A1V1

Incompressible flow

valid for steady & unsteady

incompressible flow

Cavitation

Phenomenon that occurs when the fluid pressure is reduced to the local vapor

pressure and boiling occurs.

Vapor bubbles form in the liquid, grow and collapse; producing shock wave, noise &

dynamic effects.

RESULT: lessened performance & equipment failure !

Cavitation typically occurs at locations where the velocity is high.

In case b, flow rate is higher

Cavitation damage examples

Impeller of a centrifugal pump

Spillway tunnel in a power dam

Class Exercises: (Problem 5.44)