Axial Strain

advertisement

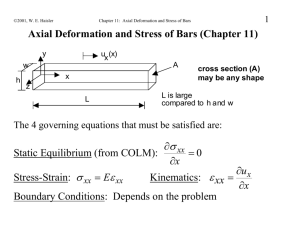

Axial Members • AXIAL MEMBERS, which support load only along their primary axis, are the most basic of structural members. • Equilibrium requires that forces in Axial Members are always Equal, Opposite, and Co-Linear. • In most cases, axial members have pinned ends. • Some examples of axial members include: – Bars; – Truss Members; – Ropes and Cables. Axial Stress • If a cut is taken perpendicular to a bar's axis, exposing an internal cross-section of area A, the force per unit area on the face of this cut is termed STRESS. • The symbol used for normal or axial stress in most engineering texts is s (sigma). • Stress in an axially loaded bar is: – s = F/A • Stress is positive in tension (P>0) and negative in compression (P<0); • English units: psi (pounds per square inch), or ksi (kilopounds per square inch); Axial Stress • The axial stress of a member is determined by: s=F/A Where F = force applied along the longitudinal axis of the member perpendicular to the cross sectional area (A). Axial Stress Example • A cylindrical steel bar has a diameter of ½” • The bar is attached at one end and a 5,000 lb weight is hung from the steel bar (axially loaded) • What is the axial stress generated in the bar? – Area of a circle = p r2 – s = F/A =5,000 lb/.20 in 2 =25,000 psi Axial Strain • An axial bar of length L, and cross-sectional area A, subjected to tensile force F, elongates by an amount, D. • The change in length divided by the initial length is termed ENGINEERING STRAIN (or simply strain). • Strain is positive in tension and negative in compression • Strain is a non-dimensional length - a fraction. • Because strain is small, it is often given as a percentage by multiplying by 100%: e.g., e = 0.003 = 0.3%. Axial Strain • Axial strain is a measure of the deformation to a member due to axial stress. e=d/L Where: e represents axial strain d represents the change in length L represents the original length Young's Modulus • Recall that all materials have a stiffness associated with them. • The stiffness of a material is defined through the relation: s = E e or E = s / e • Where: E is the YOUNG'S MODULUS or stiffness of the material. e is the axial strain s is the axial stress • Values of E for different materials are obtained experimentally from stressstrain curves. Axial Strain Example • In the previous example, a cylindrical steel bar has a diameter of ½” and a 5,000 lb weight is hung from the end (axially loaded) – Young’s Modulus for steel is 29,000,000 psi – We found the axial stress to be 25,000 psi • What is the expected strain? – s = E e or E = s / e or e = s/E • Where: – E is the YOUNG'S MODULUS or stiffness of the material. – e is the axial strain – s is the axial stress • e = (25,000 psi)/(29,000,000 psi) = .00086 or .086% Axial Strain Example (Cont.) • If the steel bar were 10 feet in length, what would the change in length be when axially loaded? • e=d/L • • • • Where: e represents axial strain d represents the change in length (deformation) L represents the original length • .00086 = d / 10 feet • .0086 feet Expected Deformation • Using Young’s Modulus, we can determine the expected deformation of a member due to a constant force being applied. FL d= AE • Where: d = Change in length F = Force applied L = Original length of member A = Cross sectional area E = Young’s Modulus Expected Deformation • Using the Stress and Strain formulas, we found the 10 foot steel rod is expected to change length by .0086 feet when axially loaded with 5,000 pounds • Using the expected deformation formula, we also find: • d = FL/AE • =(5,000 lbs)(10 ft)/(.20 in2)(29,000,000 psi) = .0086 feet