Work, Power, and Simple Machines

advertisement

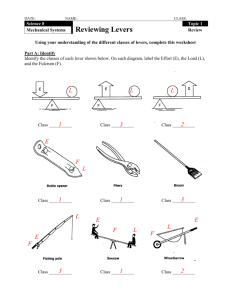

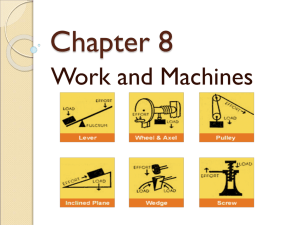

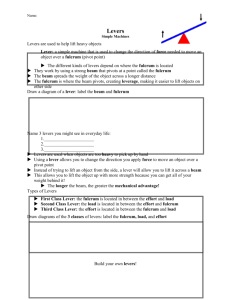

Work, Power, and Simple Machines Recall….. • An object only starts moving when a force acts on it. Work • Work is the product of the force on the object and the distance that object moves. • One thing to remember, • There maybe force on something, but that doesn’t mean that the object is doing work. For force to work on an object, some of the force must act in the same direction as the object moves. If there is no movement, there is not work being done. Work Work, if any, depends on the direction of the force and the direction of the movement Work= Force X Distance units=Joule or J Power • Power is the rate at which the work gets done. • To increase power, you can increase the amount of work done in a given time, or you can do a given amount of work in less time. Power Power=work/time unit for power is a watt Watt=j/s Horse Power • James Watt was trying to find some kind of power to compare his steam engine to and the most popular source of power at the time was a horse. Therefore, he created the horsepower to show just how powerful his method was. 1horse power=746watts Work and Machines • A machine is a device that changes a force. • Ex: a car jack Machines Machines make work easier to do. They change the size of a force needed, the direction of a force, or the distance over which a force acts Ways that Machines Work • Increasing Force– Exerts a small amount of force over a larger distance. Thus, cuts down on the amount of force you need to exerts Ways that Machines Work • Increasing Distance – Oars of a canoe show how a small distance exerted covers a much larger distance Ways that Machines Work • Change Direction – Some machines change direction of an applied force Work Input and Work Output Because of friction, the work done by a machine is always less than the work done on the machine Work Input and Work Output • The force you exert on a machine is called the input force • The distance the input force acts through is the input distance • The work done by the input force acting through the input distance is called the work input Work Input=Input Force X Input Distance Work Input and Work Output • Force that is exerted by a machine is called the output force • The distance the output force is exerted through is the output distance Work output= output force X output distance Mechanical Advantage Mechanical advantage: of a machine is the number of times that the machine increases an input force Mechanical Advantage Two types of mechanical advantage • Actual • Ideal Actual Mechanical Advantage • Determined by measuring the actual forces acting on a machine • Equals the ratio of output force to the input force Actual mechanical = output force Advantage input force Ideal Mechanical Advantage • The mechanical Advantage in the absence of Friction Because friction is always present, the actual mechanical advantage of a machine is always less than the idea mechanical advantage Ideal mechanical=input distance Advantage output distance Efficiency • The percentage of the work input that becomes work output is the efficiency of a machine Because there is always some friction, the efficiency of any machine is always less than 100 percent Efficiency Efficiency=( work output/work input)X 100 Simple Machine 6 types of simple machines • Lever • Wheel and axle • Inclined plane • Wedge • Screw • pulley Levers • A rigid bar that is free to move around a fixed point • The fixed point that the bar rotates around is the Fulcrum Levers • Input arm-The distance between the input force and the fulcrum • Output arm-The distance between the output force and the fulcrum Levers 3 types of levers • The position of the fulcrum identifies the class of the lever – First class levers – Second class levers – Third class levers First class levers • In a first class lever, the fulcrum is ALWAYS located between the input and output force • Ex: seesaw • Sissors • Tongs • Screwdriver/paint can Second Class Lever • The output force is ALWAYS located between the fulcrum and the input force » Ex: wheel barrel Third Class Lever • The input force is ALWAYS located between the fulcrum and output force Wheel and Axle • A simple machine that consists of two disks or cylinders, each one with a different radius • Ex: steering wheel • Screwdriver » The two cylinders act as a fulcrum » Incline Plane • A simple machine in which slanted surfaces along which a force moves an object to a different elevation • Ex: wheel chair ramp • Stairs Wedges • A v-shaped object whose sides are two incline planes sloped toward each other • Ex: axe – Nail – knife Screw • An incline plane wrapped around a cylinder – Two screws of the same length, the one whose threads are closer together moves forward less for each turn of the screw. – Ex: – Screw – Corkscrew Pulley • A simple machine that consists of a rope that fits in a groove in a wheel. • 3 types of pulley (figure 19 pg 432) Compound Machines • A combination of two or more simple machines that operates together • Ex: sissors, where the edges are like wedges and the blades/handles function as levers