sequencing (5) - WordPress.com

advertisement

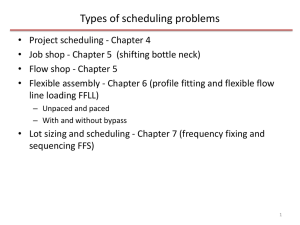

SEQUENCING PROBLEMS Sequencing A problem in which it is necessary to determine the orders or sequences of jobs in which they should be performed so as to minimize the total effectiveness on the sum of the pertinent costs is known as sequencing problems. A Sequencing problem could involve: Jobs in a manufacturing plant Aircraft waiting for landing and clearance Maintenance scheduling in a factory Programs to be run on a computer Customers in a bank. TERMS USED: JOBS – Jobs/items/customers are the primary stimulus for sequencing. Number of Machines – a machine is characterized by a certain processing capability or facilities through which a job must pass before it is completed in job. Processing Time – It means the time each job requires at each machine. Total Elapsed Time – It is the time between starting the first job and completing the last one. Idle Time – Processing It is the time the machine remains idle during the total elapsed time. Technological Order – It refers to the order in which various machines are required for completing the jobs. It is also known as Processing order. No Passing Rule – It implies that passing is not allowed i.e. the same order of the jobs is maintained over each machine. If each of njobs are to be processed on 2 machines A & B in the order AB then this rule will mean that each job will go to A first and then to B. JOB ARRIVAL PATTERN Job Arrival Pattern can be defined as the pattern in which a job arrives and joins the system. The arrival pattern may be fixed and known, variable but known and variable & unknown. Categories of Job Arrival Pattern: Static Arrival Pattern – If all jobs arrive simultaneously. Dynamic Arrival Pattern – Where the jobs arrive continuously. ASSUMPTIONS No machine can process more than one job at a time. The processing times on different machines are independent of the order in which they are processed. The time involved in moving a job from one machine to another is negligibly small. Each job once started on a machine is to be performed upto completion on that machine. All machines are of different types. All jobs are completely known and are ready for processing. A job is processed as soon as possible but only in the order specified. Types of Sequencing Problems 1. Problems with ‘n’ jobs through one machine. 2. Problems 3. 4. 5. 6. with ‘n’ jobs through two machines. Problems with ‘n’ jobs through three machines. Problems with ‘n’ jobs through ‘m’ machines. Problems with ‘n’ jobs through one machine (dependent set up time) (as Assignment ). Problems with two jobs through ‘m’ machines. Problems with ‘n’ jobs through one machine Methods Shortest Processing Time (SPT) Rule Weighted Scheduling Processing Time (WSPT) Rule Problems with ‘n’ jobs through 2 machines Methods Heuristic Method Combinatorial Method Heuristic Method Suggested by S.M.Johnson & Bellman. Procedure is as follows: 1. Select the smallest processing time occurring in the list Ai or Bj, if there is a tie select either of the smallest processing time. 2. If the smallest time is on machine A, then place it at first place if it is for the B machine place the corresponding job at the last place. Cross off that job. 3. If there is a tie for minimum time on both the machines then select machine A first and machine B last and if there is tie for minimum on machine A (same machine) then select any one of these jobs first and if there is tie for minimum on machine B then select any of these jobs in the last. 4. Repeat step 2 & 3 to the reduced set of processing 5. 6. i. ii. iii. times obtained by deleting the processing time for both the machines corresponding to the jobs already assigned. Continue the process placing the job next to the first or next to the last and so on till all jobs have been places and it is called optimum sequence. After finding the optimum sequence we can find the following: Total Elapsed Time = Total time between starting the first job of the optimum sequence on machine A and completing the last job on machine B. Idle time on machine A. Idle time on machine B. Combinatorial Method This method has three stages: 1. Compare operation time on machine A (ta) with machine B (tb). Give the code (Aa) 1 if ta > tb and code 1 if ta < tb. 2. Determine the minimum of the two operating time Ba, where Ba = min(ta, tb). 3. Give comparatic weightage of different jobs f(a), where f(a) = Aa/Ba. the optimal sequence for the job is determined by arranging the jobs in ascending order of their weights f(a). Assumption – the jobs have no priority i.e. no job is preferred to other job and storage space is available for all the jobs. Problems with ‘n’ jobs on 3 machines Job 1 2 3 4 . . i . . n Machine A Machine B A1 A2 A3 A4 . . Ai . . An B1 B2 B3 B4 . . Bi . . Bn Machine C C1 C2 C3 C4 . . Ci . . Cn There is no general solution at present however previous method given by Johnson can be applied if the following two conditions are satisfied: Condition 1 – Min Ai ≥ Max Bi and/ or Condition 2 – Min Ci ≥ Max Bi Method: Replace given problem into 2 fictitious machines G & H where, Gi=Ai+Bi, Hi=Bi+Ci, and so on Now apply same procedure and find out optimal sequence. Problems with ‘n’ jobs through ‘m’ machines Job/Machines A B C…. M 1 2 3 4 5 A1 A2 A3 A4 A5 B1 B2 B3 B4 B5 C1…. C2…. C3…. C4….. C5…. M1 M2 M3 M4 M5 n An Bn Cn…. Mn There is no solution available at present, however if any of the following conditions are met , we can proceed further: Condition 1 – Min A ≥ Max B,C,M-1 and/ or Condition 2 – Min M ≥ Max B,C,M-1 Method: Replace given problem into 2 fictitious machines G & H where, Gi=Ai+Bi+Ci+(M-1), Hi=Bi+Ci+(M-1)+M, and so on Now apply same procedure and find out optimal sequence. Alternatively convert the given problem into a no. of 2 machine sub problems. Problems with ‘n’ jobs through one machine (dependent set up time) These problems can be solved as the Assignment Problems using special case of Travelling Salesman. Problems with 2 jobs through ‘m’ machines Graphical method is used for such type of problems. The steps are given below: 1. Construct a two – dimensional graph where the X – axis represent the processing time and sequence of job 1 and the M1 machine; whereas, Y – axis represents the processing tome and sequence of job 2 on M2 machine. It may be noted that scale used must be same for both the machines. 2. Shade the area where machine would be occupied by the two jobs at the same time. 3. The processing of both jobs can be represented by a continuous path which consists of horizontal, vertical and 45 degree diagonal segment. 4. The path starts at the lower left corner and stops at the upper right corner, while avoiding the shaded area in the graph. In other words, the path is not allowed to pass through shaded areas which correspond to operating both jobs concurrently on the same machine. 5. Any horizontal movement will indicate the progress of job 1 whereas job 2 is idle. 6. Any vertical movement will reveal that the job 2 is in progress while job 1 is idle. 7. Minimum elapsed time for any job is the processing time of the job + Idle time of the same job.