BasicRefrigerationandChargingProcedures

advertisement

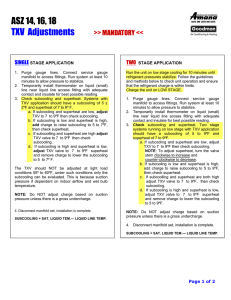

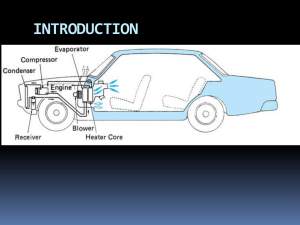

1 BASIC REFRIGERATION & CHARGING PROCEDURES 2 SECTION ONE REFRIGERANT PRESSURES, STATES & CONDITIONS 3 Load out to ambient Load in from house 4 Heat flows from hot to cold. 5 Evaporator Side Terms Evaporating Pressure Low Side Pressure Suction Pressure Back Pressure 6 Condenser Side Terms Condensing Pressure Head pressure High side pressure Discharge pressure 7 Compressor Pumps refrigerant vapor only! Divides low and high side. 8 Discharge Line Connects the compressor to the condenser. 9 Condenser Rejects heat from the refrigerant. 10 Liquid Line Supplies liquid refrigerant from the condenser to the metering device. 11 Metering Device Controls the flow of refrigerant. Divides low and high side. 12 Evaporator Absorbs heat into the refrigerant. Removes moisture from the air 13 Suction Line Returns superheated vapor from the evaporator to the compressor 14 Receiver An accessory added in the liquid line to store refrigerant for different loads placed on the system. 15 CONDENSER Temperatures Pressures States CONDENSER INLET High Pressure High Temperature Superheated Vapor Saturation Point (vapor changing to a liquid as heat is removed) Near Ambient Temperature High Pressure Subcooled Liquid OUTLET 16 17 EVAPORATOR Temperatures Pressures States 18 Evaporator inlet Low Pressure Low Temperature About 80% Liquid, 20% Vapor Saturated vapor (Temperature in which liquid is changing to a vapor) Evaporator Outlet Low Pressure Low Temperature Superheated Vapor 19 SECTION TWO SUBCOOLING & SUPERHEAT 20 Subcooling and Superheating The concepts of subcooling and superheating are the two most important principles that the service technician must understand before attempting to systematically troubleshoot hvac/r systems. 21 210 psig = 105 ºF -100 ºF Subcooling 5 ºF R-22 Condenser Subcooling 22 TOTAL SUBCOOLING 210 psig = 105 ºF -95 ºF Subcooling 10 ºF 23 Superheat Superheat is any heat added to completely saturated vapor that results in a rise in temperature (sensible heat change) of the gas. 24 60 °F 76 psig = 45 °F 15 °F superheat Evaporator Superheat 25 Total or System Superheat Suction line Temperature 60°F 76 psig = 45°F Superheat 15°F 26 SECTION THREE METERING DEVICES 27 Capillary Tube Automatic Expansion Valve Thermostatic Expansion Valve Fixed –Bore Piston 28 Capillary Tubes Low Cost device Have no moving parts Can be used on a wide range of applications 29 Thermostatic Expansion Valve Most efficient Maintains a constant evaporator superheat Helps prevent compressor flooding 30 TXV Types Pressure Limiting Balance Port Externally equalized Internally Equalized Electric operated TXV Bulb Placement 31 32 TXV External Equalizer Tap Location 33 Automatic Expansion Valves Maintain a constant evaporator pressure Used on small systems which have constant loads 34 Fixed-Bore Metering Devices Most common today on Residential systems Dual purpose device Works as metering a device Works as a check valve Critical charge 35 SECTION FOUR System CHARGE 36 Is The Refrigerant Charge Correct? All refrigeration systems differ in the amount of charge they hold. There are guidelines, charts, and techniques to follow. System design & layout must be known 37 How long & what size is the line set? What’s the volume of the filter drier? 38 TXV CHARGING RULES 1. Charge system under a high load 2. Charge as a liquid when possible 3. Throttle liquid blends into low side 4. Record evaporator & compressor superheat & Condenser subcooling 39 AIRCONDITIONING SYSTEMS Capillary Tube or Fixed Orifice #1 Weigh in the correct charge #2 Manufacture's charging charts #3 Use system superheat method 40 Requirements for system superheat charging Proper evaporator air flow Accurate remote bulb temperature tester Accurate gauge manifold set 41 What should the Superheat be? SYSTEM SUPERHEAT CHARGING Indoor Wet-Bulb Air Temperature 65ºF Condenser 70ºF Entering 75ºF Air 80ºF Temperature 85ºF 90ºF 52 54 56 58 60 62 64 66 68 70 72 74 76 6 10 13 16 19 21 24 27 30 33 36 38 41 7 10 13 16 19 21 24 27 30 33 36 39 6 9 12 15 18 21 24 28 31 34 37 5 8 12 15 18 21 25 28 31 35 8 11 15 19 22 26 30 33 5 9 13 16 20 24 27 31 6 10 14 18 22 25 29 8 12 15 20 23 27 95ºF 100ºF To increase superheat remove refrigerant. To decrease superheat add refrigerant. 42 System Superheat Suction line Temperature 60 °F 76 psig = 45 °F Superheat 15 °F 43 AIR FLOW Can be measured in many ways 1. Equipment data charts 2. Air flow meters 3. Combination of meter readings and formulas 44 Sensible Heat Formula CFM = Sensible heat BTU’s 1.08 X temperature difference 45 Sensible Heat Formula Electric Heat BTU’s = Heater amps X volts X 3.41 Sensible heat BTU’s CFM = 1.08 X temperature difference 46 Sensible Heat Formula 3 Phase Electric Heat BTU’s = Heater amps X volts X 3.41 X 1.73 Sensible heat BTU’s CFM = 1.08 X temperature difference 47 Sensible Heat Formula Fossil Fuel Heat BTU’s = Heater input X Efficiency or Bonnet capacity CFM = Sensible heat BTU’s 1.08 X temperature difference 48 Measuring Duct Velocity CFM = Velocity X Area in square feet 49 SAMPLE QUESTIONS 50 The high and low pressures in a refrigeration system are separated by: a. The compressor. b. The evaporator. c. The metering metering device. device. The d. The filter drier. 51 Subcooling can be defined as: a. The cooling effect of an evaporator. b. Any sensible heat removed from 100% saturated liquid. c. The superheat that is removed at the top of the condenser. d. The cooling of the compressor motor by returning refrigerants. 52 Always charge a TXV with a receiver and sightglass under a: a. No load condition. b. Low load condition. c. High load condition. d. None of the above. 53 Superheat is defined as: a. The heat added the the saturated liquid. b. Heat removed from the saturated liquid in the condenser. c. The heat added to the saturated vapor vapor exiting exiting the the evaporator. evaporator. d. The heat removed from the saturated vapor exiting the evaporator.