The Laminate

Composites Design and Analysis

Stress-Strain Relationship

Prof Zaffar M. Khan

Institute of Space Technology

Islamabad

2

Next Generation Aerospace Vehicle Requirements

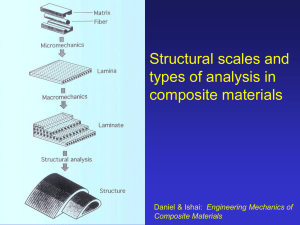

Composite design and analysis

Laminate

Theory

Manufacturing

Methods

Materials

Composite

Materials Design /

Analysis Engineer

Design

Guidelines

Design Data

Quality

Assurance

4

MATERIAL SELECTION

The design/analysis engineer should be able to determine for the following question:

How do composite laminates behave under load?

Which composite material should be used?

What are the guidelines for design and the analysis methods?

What design data is required and how is it obtained?

Can the composite product be fabricated easily?

How can the quality of the composite product be assured?

The purpose of the material presented here is to introduce the reader to the principles of the mechanical behavior of thin laminates (how laminates behave under loads). This includes both symmetric and unsymmetric laminates relative to the mid-plane, with both in-plane and flexural loads. Also included are the effects of temperature and moisture, and laminate strength. A liberal use is made of flow charts for aids in analysis

2D

Composite Analysis

vs.

3D

State of Stress

6

Required elastic material properties for composites

• Metals (isotropic materials)

– E, G, ν

– 2 independent properties – G = __E____

2(1 + ν)

• Composite lamina (unidirectional layer, ply)

–

–

In plane: E

1

, E

2

, G

Out of plane : E

3

12

, G

, ν

13

12

, G

23

, ν

13

, ν

• But for transverse isotropy (2 = 3):

23

E

2

= E

3

G

12

= G

13

ν

12

= ν

13

G

23

= __E

23

___

2(1 + ν

23

)

Therefore 5 independent properties:

E

1

E

2

G

12

ν

12

G

23

Terminology used in micromechanics

•

E f

, E m

•

G f

, G m

- Young’s modulus of fiber and matrix

- Shear modulus of fiber and matrix

• ν f

, ν m

•

V f

, V m

- Poisson’s ratio of fiber and matrix

•

W f

, W m

- Volume fraction of fiber and matrix

– Weight fraction of fiber and matrix

Elastic properties:

Rule of mixtures approach

• Parallel model - E

1 and ν

12

(Constant Strains)

E

1

= E f1

V f

+ E m

V m

ν

12

=

ν

f

V f

+ ν m

V m

Predictions agree well with experimental data

• Series model – E

2 and G

12

(Constant Stress)

E

2

=

__ __

E f2

E m

________

E f2

V m

+ E m

V f

G

12

=

__

__

E f2

E m ________

E f2

V m

+

E m

V f

Experimental results predicted less accurately

Micromechanics example:

Volume fraction changes

Knowns : Carbon: E = 34.0 x 10 6 psi

Epoxy : E = 0.60 x 10 6 psi

• How much does the longitudinal modulus change when the fiber volume fraction is changed from 58% to 65%?

E

1

= E f1

V f

+ E m

V m

For

V f

= 0.58:

E

1

= (34.0 x 10 6 psi)(.58) + (0.60 x 10 6 psi)(0.42) = 20.0 x 10 6 psi

For

V f

= 0.65:

E

1

= (34.0 x 10 6 psi)(.65) + (0.60 x 10 6 psi)(0.35) = 22.3 x 10 6 psi

Thus, raising the fiber volume fraction from 58% to 65% increases E 1 by

12%

Design and analysis of composite laminates:

Laminated Plate Theory (LPT)

• Used to determine the response of a composite laminate based on properties of a layer (or ply)

Laminate Ply Orientation Code

• Designate each ply by it’s fiber orientation angle

• List plies in sequence starting from top of laminate

• Adjacent plies are separated by “/” if their angle is different

• Designate groups of plies with same angle using subscripts

• Enclose complete laminate in brackets

• Use subscript “S” to denote mid plane symmetry, or “T” to denote total laminate

• Bar on the top of the ply indicates mid-plane

Special types of laminates

• Symmetric laminate – for every ply above the laminate mid plane, there is an identical ply(material and orientation) an equal distance below the mid plane

• Balanced laminate – for every ply at a +θ orientation, there is another ply at the – θ orientation somewhere in the laminate

• Cross-ply laminate – composed of plies of either 0 o or 90 o (no other ply orientations)

• Quasi-isotropic laminate – produced using at least three different ply orientations, all with equal angles between them. Exhibits isotropic extensional stiffness properties (have the same E in all in-plane directions)

The response of special laminates

• Balanced, unsymmetric, laminate

– Tensile loading produces twisting curvature

– Ex: [+θ/0/- θ]τ

• Symmetric, unbalanced laminate

– Tensile loading produces in-plane shearing

– Ex: [+θ/0/- θ]τ

• Unsymmetric cross-ply laminate

– Tensile loading produces bending curvature

– Ex: [0/90]

τ

• Balanced and symmetric laminate

– Tensile loading produces extension

– Ex: [+θ/- θ] s

• Quasi isotropic laminate: [+60/0/- 60] s and [+45/0/+45/90] s

– Tensile loading produces extension loading, independent of angle

Stress-Strains Relationships in Lamina

(1) The lamina is homogeneous, orthotropic and linear-elastic

(2) The lamina is in a state of plane stress (very thin), therefore, the stresses associated with the z-direction are negligible: σ z

= τ xz

= τ yz

= 0

The normal strain in the x-direction for the lamina in Figure 2a is the sum of the normal strains in the x-direction for the laminae in Figures 2b, 2c and 2d:

From Figure 2b, ε x

= 0

x

From Figure 2c, E x

=

x

From Figure 2d, ν y

= −

x y

or ε x

= or ε

E x x x

= − ν y

ε y

= − ν y

y

E y

Consequently, the total normal strain in the x-direction is or

ε

ε x

= 0 +

x

E x x

=

x

E x

− ν y

− ν y

E y y

y

E y

The normal strain in the y-direction for the lamina is determined from superposition as follows:

From Figure 2b, ε y

= 0

From Figure 2c, ν x

= −

y

x

y

From Figure 2d, E y

=

y or ε y

= − ν x

ε x

= − ν x

or ε y

=

E y y

x

E x

Consequently, the total normal strain in the y-direction is

ε y

= 0 − ν x or

ε y

= − ν x

E x x

x

E x

+

+

y

E y

E y

y

(2)

The shear strain, which is independent of the normal strains, is determined as follows:

From Figure 2b, E s

=

s s

or ε s

=

E s s

From Figure 2c, ε s

= 0

From Figure 2d, ε s

= 0

s

Therefore, the shear strain associated with the x-y coordinate system is; ε s

=

E s

(3)

If we express Equations (1), (2) and (3) in matrix form, we have

s x y

=

1

E

x x

E x

0

y

E y

1

E y

0

0

0

1

E s

s x y

=

S xx

S yx

0

S xy

S yy

0 S

0

0 ss

s x y

Equation (4) may also be expressed as follows:

s x y

=

1

1

x

x

E y y

E x

x

0 y

y

E x

1

x

y

E y

1

x

y

0

0

0

E s

s x y

=

Q xx

Q yx

0

Q xy

Q yy

0

0

0

Q ss

s x y

[ε] = [C] [σ]

[σ] = [M] [ε]

(4)

(5)

Elastic Constants-x

P lbs

σ x

= P/A psi

ε x in/in

ε y in/in

ν x

= − ε y

/ ε x

0

105

0

1872

0 0

0.000520

− 0.000073

200

300

400

500

3565

5348

7398

8913

0.001005

0.001495

0.002165

0.002515

− 0.000140

− 0.000210

− 0.000245

− 0.000340

600 10695 0.003022

− 0.000405

700 12478 0.003545

− 0.000460

800 14260 0.004050

− 0.000520

ν x

= 0.135 (average)

0.140

0.139

0.140

0.136

0.135

0.134

0.130

0.128

Elastic Constants-y

P lbs

σ y

= P/A psi

0

100

0

1751

ε

0 x in/in

− 0.000075

ε y in/in

0

0.000540

ν y

= − ε x

/ ε y

0.139

200

300

400

500

3503 − 0.000145

5254 − 0.000210

7005 − 0.000285

8757 − 0.000350

600 10508 − 0.000415

700 12259 − 0.000470

800 14011 − 0.000540

0.001090

0.001628

0.002218

0.002793

0.003351

0.003943

0.004620

ν y

= 0.127 (average)

0.133

0.129

0.128

0.125

0.124

0.119

0.117

σ y

vs ε y

σ y

(psi)

8000

6000

4000

2000

0

0

14000

12000

10000

E y

= σ y

/ ε y

= 3.05 x 10

6

psi

0.001

0.002

ε y

(in/in)

0.003

0.004

0.005

Elastic Constants-s

P σ lbs s

= P/2A psi

ε

μ in/in

ε

ν in/in

400

500

600

700

800

0

100

200

300

0

875

1748

2622

3497

4371

5245

6119

6993

0

0.001075

0.002212

0.003527

0.005175

0.007219

0.010547

0.013412

0.019082

0

− 0.000561

− 0.001229

− 0.002065

− 0.003164

− 0.004615

− 0.007250

− 0.009630

− 0.014710

ε s

= ε

μ

− ε

ν in/in

0

0.001632

0.003441

0.005592

0.008339

0.011834

0.017797

0.023042

0.033792

Determination of Elastic Constants

Type Material E x

E y

ν x

E s t

Type

T300/5208

Material E x

E y

ν x

E s

ν f

Specific gravity

Typical thickness

Graphite/Epoxy

GPa

181

GPa

1.3

0.28

GPa

7.17

0.70

1.6

meters

0.000125

B(4)/5505

AS/3501

Boron/Epoxy

Graphite/Epoxy

204

138

18.5

8.96

0.23

0.30

5.59

7.1

0.50

0.66

2.0

1.6

0.000125

0.000125

Scotchply 1002

Kevlar 49/Epoxy

Glass/Epoxy

Aramid/Epoxy

38.6

76

8.27

5.5

0.26

0.34

4.14

2.3

0.45

0.60

1.8

1.46

0.000125

0.000125

T300/5208

B(4)/5505

Graphite/Epox y

Msi Msi Msi

26.25

1.49

0.28

1.04

inches

0.005

Boron/Epoxy 29.59

2.68

0.23

0.81

0.005

AS/3501 Graphite/Epox y

20.01

1.30

0.30

1.03

Scotchply 1002 Glass/Epoxy 5.60

1.20

0.26

0.60

0.005

0.005

Kevlar 49/Epoxy Aramid/Epoxy 11.02

0.80

0.34

0.33

0.005

Transformation of Stress and Strain

Area

Stresses

Stresses

Forces

These three equilibrium equations may be combined in matrix form as follows:

The equations for the transformation of strain are the same as those for the transformation of stress:

Stress-Strain Relationships in Global Coordinates

Develop the relationship between the stresses and strains in global coordinates.

[σ

[σ xys xys

] = [Q xys

] [ε

] = [T] [ σ

[ε xys

] = [Ť] [ε

126

] xys

126

]

]

Substitution of Equations (2) and (3) into (1) yields

[T] [ σ

126

] = [Q xys

] [Ť] [ε

126

]

(3)

(1)

(2)

(4)

Pre multiplying both sides of Equation (4) by [T] −1 :

[T] −1 [T] [σ

126

] = [T] −1 [Q or [ σ

126 xys

] [Ť] [ε

126

] = [T] −1 [Q xys

] [Ť] [ε

126

]

] (5)

(6) or = [T] −1 [Q xys

] [Ť] (7)

or = [Q

126

] or [ σ

126

] = [Q

126

] [ε

126

] where [Q

126

] = [T] −1 [Q xys

] [Ť]

Note that [T

(+θ)

] −1 = [T

(−θ)

]

The elements of the matrix [Q

126

] are as follows:

Q

11

Q

22

Q

12

Q

66

Q

16

Q

26

= Q

= Q

= Q

= Q

= Q xx xx

21

= (Q xx

61

62 cos 4 θ + 2 (Q xy sin 4 θ + 2 (Q xy

= (Q xx

+ Q yy

+ 2 Q ss

) sin 2 θ cos 2 θ + Q

+ 2 Q ss

− 4Q ss

) sin 2 θ cos 2 θ + Q yy sin 4 θ

) sin 2 θ cos 2 θ + Q yy cos 4 θ

(sin 4 θ +cos 4 θ)

+ Q

= (Q

= (Q yy xx xx

− 2 Q xy

– Q xy

− 2Q ss xy

) sin 2 θ cos 2 θ + Q ss

− 2Q ss

) sinθ cos 3 θ + (Q xy

(sin

– Q yy

4 θ +cos 4 θ)

– Q xy

− 2Q ss

) sin 3 θ cosθ + (Q xy

– Q yy

+ 2Q ss

+ 2Q ss

) sin 3 θ co

) sinθcos 3 θ

[Q

126 or

] −1 [ σ

[Q

126

] = [Q

126

] −1 [ σ or

126

] −1 [Q

126

] [ε

126

]

126

] = [ε

126

]

[ε

126

] = [Q

126

] −1 [ σ

126

] or [ε

126

] = [S

126

] [ σ

126

] or

The elements of the matrix [S

126

] are as follows:

S

11

= (Q

22

Q

66

– Q

26

2 ) / ∆

S

12

S

S

16

S

22

26

S

66

= S

= S

21

61

= (Q

= S

62

= (Q

11

11

= (Q

= (Q

12

Q

= (Q

12

Q

66

22

16 where ∆ = Q

11

Q

Q

26

Q

– Q

26

16

2

Q

– Q

16

12

2

22

Q

– Q

66

12

) / ∆

) / ∆

Q

66

– Q

22

Q

16

– Q

11

Q

26

+ 2 Q

) / ∆

) / ∆

) / ∆

12

Q

26

Q

61

− Q

22

Q

16

2 – Q

66

Q

12

2 – Q

11

Q

62

2

Summary: Lamina Analysis

The Symmetric Laminate with In-Plane Loads

A.

Stress Resultants and Strains: The “A”

Relationship between strains and the stress resultants. Related by constants A ij

Deriving expressions for these constants:

Expression for is:

Expression for N

1:

N

1

= (σ

1

)

1

(h

1

-h

2

) + (σ

1

)

2

(h

2

-h

3

) + (σ

1

)

3

(h

3

-h

4

) + …

Substitute the expressions for stress:

Above equation can be rewritten as:

Similarly for N

2 and N

6:

Above can be combined into matrix form as:

Or

Where

A

11

A

12

A

16

A

22

A

26

A

66

= (Q

11

) k

= (Q

12

) k

= (Q

16

) k

= (Q

22

) k

= (Q

26

) k

= (Q

66

) k t k t k t k t k t k t k

Example

Determine the elements of [A] for a symmetric laminate of 6 layers: [0/45/90] s

The material of each lamina is Gr/Ep T300/5208 and t=0.005” = 0.000125 m

.

0° Lamina

Q

11

Q

22

Q

12

Q

66

Q

16

Q

26

= 0

= Q xx

= Q yy

= Q xy

= Q ss

= 0

= 181.8

= 10.34

= 2.897

= 7.17

Q

11

Q

22

Q

12

Q

66

90° Lamina

= Q yy

= Q xx

= Q xy

= Q ss

= 10.34

= 181.8

= 2.897

= 7.17

Q

16

Q

26

= 0

= 0

Q

11

Q

22

Q

12

Q

66

Q

16

Q

26

Q

11

= Q xx

= Q xx

= Q

21

= (Q

= Q

= Q xx

61

62 cos 4 θ + 2 (Q xy sin 4 θ + 2 (Q xy

= (Q

+ Q

= (Q

= (Q xx yy xx xx

+ Q yy

– 2Q xy

– Q

– Q xy xy

+ 2 Q

– 4 Q ss ss

) sin

) sin 2 θ cos 2 θ + Q xy

– 2 Q ss

) sin 2

2 θ cos 2 θ + Q

+ 2 Q ss

) sin 2 θ cos 2 θ + Q yy cos 4 θ

(sin 4 θ + cos 4 θ)

θ cos 2 θ + Q ss

– 2 Q ss

) sinθ cos 3 θ + (Q xy

– 2 Q ss

) sin 3 θ cosθ + (Q xy yy sin

(sin

– Q yy

– Q yy

4

4 θ

θ + cos 4 θ)

+ 2 Q ss

) sin 3 θ cosθ

+ 2 Q ss

) sinθ cos 3 θ

= 0.25 Q xx

+ 2 (Q xy

+ 2 Q ss

) (0.25) + 0.25 Q yy

= 56.65

Q

22

= 0.25 Q xx

+ 2 (Q xy

+ 2 Q ss

) (0.25) + 0.25 Q yy

= 56.65

Q

12

= (Q xx

+ Q yy

– 4 Q ss

) (0.25) + Q xy

(0.5) = 42.31

Q

66

= (Q xx

+ Q yy

– 2 Q xy

–2Q ss

) (0.25) + Q ss

(0.25) = 46.59

Q

16

= (Q xx

– Q xy

– 2 Q ss

) (0.25) + (Q xy

– Q yy

+2 Q ss

) (0.25) = 42.87

Q

26

= (Q xx

– Q xy

– 2 Q ss

) (0.25) + (Q xy

– Q yy

+2 Q ss

) (0.25) = 42.87

The Laminate

A

11

= 0.000125 (181.8 + 10.34 + 56.25) 2 = 0.0622

A

22

= 0.000125 (10.34 + 181.8 + 56.65) 2 = 0.0622

A

12

= 0.000125 (2.897 + 2.897 + 42.31) 2 = 0.0120

A

66

= 0.000125 (7.17 + 7.17 + 46.59) 2 = 0.0152

A

16

= 0.000125 (0 + 0 + 42.87) 2 = 0.0107

A

26

= 0.000125 (0 + 0 + 42.87) 2 = 0.0107

GPa-m

Equivalent Engineering Constants for the Laminate

Equation for the composite laminate is

Or [N] = [A] [ε]

Matrix equation for a single orthotropic lamina or layer is

Or [σ] = [M] [ε]

The properties of the single “equivalent” orthotropic layer can be determined from the following equation: or 1 h

[A] = [M]

A

11

= E

1

1

1

2

1 h

A where h = laminate thickness

12

=

2

E

1

1

1

2

1 h

A

66

= E

6

1 h

A

22

= E

2

1

1

2

1 A

21

= h 1

1

E

2

1

2

Solving last equation, we have the following elastic constants for the single “equivalent” orthotropic layer:

E

1

A

11

= (1 – h

A

12

2

A

11

A

22

) E

2

=

A

22 h

(1 –

A

12

2

A

11

A

22

)

E

6

1

= A

66 h

ν

1

=

A

12

A

22

ν

2

=

A

12

A

11

The equation for the composite laminate is or where

[ε] = [a] [N]

[a] = [A] -1

The equation for a single orthotropic lamina is or [ε] = [C] [σ]

The properties of the single “equivalent” orthotropic layer is determined by

[a] h = [C]

1 or a

11 h =

E

1 a

21 h =

1

E

1 a

12 h =

E

2

2

1 a

22 h =

E

2

1 a

66 h =

E

6 elastic constants for the single “equivalent” orthotropic layer:

E

1

= 1 a

11 h

E

2

= 1 a

22 h

E

66

= 1 a

66 h

ν

1

= – a

12 a

11

ν

2

= – a

12 a

22

Special Cases:

•

• Cross-Ply Laminates: All layers are either 0° or 90°, which results in A

16 and Table 1.

= A

26

= 0. This is sometimes called specially orthotropic w. r. t. in-plane force and strains. Refer to Figure 1

• h = total laminate thickness

Figure 1 In-Plane Modulus and Compliance of T300/5208 Cross-

Ply Laminates.

• Balanced Angle-Ply Laminates: There are only two orientations of the laminae; same magnitude but opposite in sign. With an equal number of plies with positive and negative orientations. Refer to

Figure 2 and table 2 .

• h = total laminate thickness.

Figure 2 In-Plane Modulus and Compliance of T300/5208 Angle-Ply Laminates .

The balanced angle-ply laminate is another case of “special orthotropy” w.r.t. inplane force and strains; that is A

16

= A

26

= 0.

The values of Table 2 apply for un-symmetric laminate as well as symmetric laminates. For example, the values for [+30, −30, +30, −30] or [+30, +30, −30, −30] are the same as those for [+30, -30, -30, +30].

If the laminate is not balanced, such as [+30, −30, +30], then the terms A

16 are not zero.

and A

26

Also remember that A

16 symmetric.

= A

26 for all cross-plies, whether they are symmetric or un-

Example:

[0, 90]

[0, 90, 0]

[+30, −30, −30, +30]

[+30, −30, +30, −30]

[+30, −30, +30] un-symmetric cross-ply, A symmetric cross-ply, A

16

16

= A

= A

26

26

= 0

= 0 symmetric balanced angle-ply, A symmetric un-balanced angle-ply, A

16

, A

26

16

= A

26 un-symmetric balanced angle-ply, A

16

≠ 0

= 0

= A

26

= 0

3) Quasi-Isotropic Laminates :

Has ‘m’ ply groups spaced at ply orientations of 180/m degrees.

Note: This does not apply for m = 1 and m = 2. The laminate need not be symmetric to be quasi-isotropic. For example, the laminate [0, 45, −45, 90] is quasi-isotropic.

Examples:

[0/60/−60]s

[0/90/45/−45]s

[0/60/−60/60/0/−60]s m = 3 m = 4 m=3

180/m = 60°

180/m = 45°

180/m = 60°

The modulus of the quasi-isotropic laminate has the following properties:

A

11

A

16

A

66

= A

22

= A

26

= (A

11

= 0

– A

22

1

) which is equivalent to G =

2 1

E

for an isotropic material.

Summary: Laminate Analysis

1.

Determine the modulus for the laminate [0/+45/−45/90] s

where the 0° and 90° layers are

Scotch-ply 1002, and the +45° and −45° layers are T300/5208. The thickness of each layer is 0.00125m. Obtain the modulus by (1) hand calculations, and (2) computer program.

Answer:

N

N

N

6

1

2

=

0

0

.

402

.

222

0

10

8

10

8

0

0

.

222

.

402

0

10

10

8

8

0 .

254

0

0

10

8

1

6

2

2.

A stress analysis of a structure results in the stresses shown at a particular point in a composite laminate. The laminate is the same as in problem 5. a.

Determine the strains in global coordinates.

Answers: 0.00358, -0.00198, 0.00158 b.

Determine the stresses in the 0° lamina in local coordinates. c.

Determine the stresses in the 45° lamina in local coordinates.

Answers: 2.887 MPa, 4.68 MPa, -39.84 MPa