Calculate dCA/dt for Reversible Reaction

advertisement

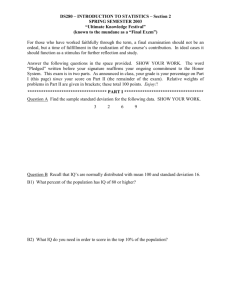

Department of Chemical Engineering Faculty of Engineering Universitas Indonesia 2013 HOMOGENEOUS HETEROGENEOUS Form Soluble metal complexes, usually mononuclear Metals, usually supported, or metal oxides Active site Well-defined, discrete molecules Poorly defined Phase Liquid Gas/Solid Temperature Low (<250C) High (250-500oC) Activity High Variable Selectivity High Variable Diffusion Facile Can be very important Heat transfer Facile Can be problematic Product separation Generally problematic Facile Catalyst recycle expensive simple Catalyst modification Easy Difficult Reaction mechanism Reasonably well understood Not obvious Sensitivity to deactivation Low High Definition HOMOGENEOUS REACTION all reactants are in the same phase HETEROGENEOUS REACTION more than one phase in reactants Equilibrium Constant Rate (K) Equal between forward and reverse reaction Difference between forward and reverse reaction Surface area affects the reaction rate No Yes Example 3H2(g) + N2(g) --> 2NH3(g) Zn(s) + 2HCl(aq) --> H2(g) + ZnCl2(aq) Ag+(aq) + Cl-(aq) --> AgCl(s) C(s) + O2(g) --> CO2(g) CATALYST Definition Molecular weight Alternate terms Reaction rate BIOCATALYST may be broadly defined as the use of catalysts are substances that enzymes or whole cells to increase increases or decrease the rate of speed in which a reaction takes place a chemical reaction but remain but do not affects the unchanged thermodynamics of reaction low molecular weight High molecular weight globular compounds protein or whole cells Inorganic catalyst Organic catalyst Typically slower Several times faster Specificity They are not specific and therefore end up producing residues with errors Conditions High temperature Example vanadium oxide Biocatalyst are highly specific producing large amount of good residues Mild conditions, physiological pH and temperature amylase, lipase Steps in a Catalytic Reaction: 1. Mass transfer (diffusion) of the reactant(s) (e.g., species A) from the bulk fluid to the external surface of the catalyst pellet 2. Diffusion of the reactant from the pore mouth through the catalyst pores to the immediate vicinity of the internal catalytic surface 3. Adsorption of reactant A onto the catalyst surface 4. Reaction on the surface of the catalyst (e.g., AB) 5. Desorption of the products (e.g., B) from the surface 6. Diffusion of the products from the interior of the pellet to the pore mouth at the external surface 7. Mass transfer of the products from the external pellet surface to the bulk fluid The reaction given below: The solution is: (Pseudo Equilibrium) The reaction given below: The solution is: Apparatus for the volumetric method Sensitive beam-type balance used for the gravimetric method Equipment arrangement for the dynamic method Dinitrogen adsorption data: P/P0 Volume adsorbed (cm3/g) Sample 1 Sample 2 0.02 23.0 0.15 0.03 25.0 0.23 0.04 26.5 0.32 0.05 27.7 0.38 0.10 31.7 0.56 0.15 34.2 0.65 0.20 36.1 0.73 0.25 37.6 0.81 0.30 39.1 0.89 (a)Calculate the BET surface area per gram of solid for Sample 1 using the full BET equation and the one-point BET equation. Are the values the same? What is the BET constant? (b)Calculate the BET surface area per gram of solid for Sample 2 using the full BET equation and the one-point BET equation. Are the values the same? What is the BET constant and how does it compare to the value obtained in (a)? Normal boiling point of dinitrogen is 77 K and the saturated vapour pressure P0 = 1.05 bar = 101.3 kPa. Assuming mass of each sample is 1 gram. Table modification for the answer: Sample 1 P/P0 P (kPa) Sample 2 Volume Volume adsorbed adsorbed (cm3/g) (cm3/g) 0.02 2.026 99.274 23.0 0.000887 0.15 0.136 0.03 3.039 98.261 25.0 0.00124 0.23 0.134 0.04 4.052 97.248 26.5 0.00157 0.32 0.130 0.05 5.065 96.235 27.7 0.0019 0.38 0.139 0.10 10.13 91.17 31.7 0.0035 0.56 0.198 0.15 15.195 86.105 34.2 0.00515 0.65 0.271 0.20 20.26 81.04 36.1 0.00693 0.73 0.342 0.25 25.325 75.975 37.6 0.00887 0.81 0.412 0.30 30.39 70.91 39.1 0.011 0.89 0.482 Equation needed: C s 1 i BET surface area for Sample 1 using the one-point BET equation: Plotting V against P to get the ‘Point B’ as VM 45 y = 0.5423x + 24.253 40 35 30 25 20 0 5 10 15 20 25 30 35 VM = 27.7 cm3/g = 2.77 x 10-8 m3/g, then using Eq. 2 specific area of solid for Sample 1 is 7.45 x 10-3 m2/g BET surface area for Sample 1 using the full BET equation: From Eq. 1, plotting data in the form P/[V(P0-P)] against P/P0 to get slope (s) & intercept (i) that 1/(s + i) is equal to VM. From graphic, VM = 28.49 cm3/g = 2.849 x 10-8 m3/g then using Eq. 2 specific area of solid for Sample 1 is 7.66 x 10-3 m2/g Graphic full BET method of solid for Sample 1: 0.012 y = 0.0353x + 9E-05 0.01 0.008 0.006 0.004 0.002 0 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 BET constant for Sample 1: Using Eq. 3, then BET constant of solid for Sample 1 is = 389.889 BET surface area for Sample 2 using the one-point BET equation: Plotting V against P to get the ‘Point B’ as VM 1.2 1 y = 0.0244x + 0.211 0.8 0.6 0.4 0.2 0 0 5 10 15 20 25 30 35 VM = 0.38 cm3/g = 3.8 x 10-10 m3/g, then using Eq. 2 specific area of solid for Sample 1 is 1.02 x 10-4 m2/g BET surface area for Sample 2 using the full BET equation: From Eq. 1, plotting data in the form P/[V(P0-P)] against P/P0 to get slope (s) & intercept (i) that 1/(s + i) is equal to VM. 0.6 0.5 y = 1.2903x + 0.086 0.4 0.3 0.2 0.1 0 0 0.05 cm3/g 0.1 10-10 0.15 m3/g, 0.2 0.25 0.3 0.35 VM = 0.72 = 7.2 x then using Eq. 2 specific area of solid for Sample 1 is 1.95 x 10-4 m2/g BET constant for Sample 2: Using Eq. 3, then BET constant of solid for Sample 2 is = 16 Difference value of surface area using one-point BET eq. and full BET eq. : Discrepancy value between those method illustrated the dangers in relying on the estimation of a single point either by inspection (point B method) therefore point B is not particularly well defined and the BET full method more empirical. Comparison of BET constant between Sample 1 and 2 : Comparison of the BET constant obtained from Sample 1 & 2 indicated its depends on the difference on volume adsorbed of each sample that showed by slope and intercept of line that used to calculate the layer of adsorbed gas quantity