Re-designing Blue Archipelago Berhad Intensive Shrimp Farm in

advertisement

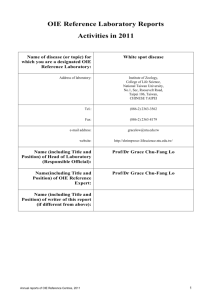

RE-DESIGING BLUE ARCHIPELAGO INTENSIVE SHRIMP FARM IN MALAYSIA BIOSECURE MODULE SYSTEM COMBINED WITH BIOFLOC TECHNOLOGY Nyan Taw*, Poh Yong Thong, Ling Teck Ming, Chatree Tanabatra, Kamel Zikry Sallah & Mohd Afiq Md Razi Blue Archipelago BHD www.bluearchipelago.com June 6 -10, 2011 NATAL CONVENTION CENTER NATAL, BRAZIL BACKGROUND Shrimp (L. vannamei) farming has become competitive and as such technology starting from biosecure farm design and operation system utilized is essential for sustainable production. This has been proven by re-engineering from pond base culture to module base biosecure system at a large shrimp farm in Indonesia (Nyan Taw et.al., 2007). The basic concept of biofloc technology was provided by Avnimelech (2000, 2005a&b). The system was successfully applied in commercial culture of shrimps by McIntosh (2000a, b & c, 2001), McNeil (2000), Nyan Taw (2004, 2005, 2008 & 2010). Smith et al (2007) successfully used biofloc technology on Penaeus monodon in earthen ponds in Australia. Shrimp farm biosecurity was given by Nyan Taw (2010). Successful redesigning and production using biosecurity and biofloc technology was also provided very recently by Nyan Taw (2011). Blue Archipelago intensive shrimp farm, Arca Biru SDN, is located at Kedah, northwest of Kuala Lumpur. The farm was established in early 1990s for Penaeus monodon culture. However, the farm was faced with serious viral (WSSV) outbreaks. In early 2010, the farm was re-designed from pond base to biosecure module base system including two modules lined with HDPE. For the remaining modules, only pond dikes were lined. The farm was operated with minimum water exchange, semibiofloc and biofloc technology. The main objective of the cycle was to have a bench-mark for future production cycles as such a number of commercial trials were tried. Arca Biru (BAB) Shrimp Farm, Malaysia Seawater source 2.4 KM Farm Location West Malaysia 1999 Module Base system THE CHANGES CPB Lampung Modules Earthen & HDPE lined ponds (0.5ha). Recirculation system Nyan Taw WAS 2005 Bali Farmer session Nyan Taw, Shrimp Farm Indo GAA 2005 Module Base system Dipasena WM 2000 Pond Base in rows 2006 1995 Nyan Taw et al Reengineering Dipasena GAA 2008 Dipasena Pond base in rows changed to Module base operation system in 2006 – reservoirs and culture ponds NT Dec09 Before Re-designing – Module ? Biosecurity ? Bird scare lines Reservoir pond Reservoir pond Not used Reservoir pond Reservoir pond Fish Dead WSSV shrimps after harvest – not removed Crabs SI Canal –cannot dry Out let leaks Sludge center pond – not removed Nets – 1000 micron Sub Inlet gate - leaks Crab fence – not maintainted Nets – 1000 micron Nets – 1000 micron ? Out let gates - Leaks Black sludge now removing BIOSECURITY What we are protecting from ? Basic WSSV Characters 1. Mass mortality: DOC <45 days 2. Temperature >30 less prone; <29 more prone; <26 dangerous. 3. Onset of heavy rain (season) with low temperature trigger outbreaks. Seasonal occurrence is well document. 4. Virus dies in free water in 72 hours 5. Crustacean are carrier (crabs) – lives with virus. 6. Virus lives in freshly dead, indefinitely in fresh processed frozen condition 7. Virus can live and a very few can survive after mass mortality 8. No evident of wind carrying WSSV from pond to pond 9. Bacteria white patch (spots) on carapace can be mistaken as WSSV spots. Arca Biru SDN BHD - Layout 2 Module HDPE + 6.5 Module HDPE At Dyke + 0.5 Module LDPE At Dyke – 9 modules Operated only 1 Module HDPE + 6 Modules HDPE at Dike – 7 modules Bio-secure Module system – Arca Biru Arca Biru, Malaysia Biosecure module - after re-designed Biosecurity – crab fence & bird scare lines HDPE lined ponds with center drain, secured outlet gates & Main supply canal Pond out let gate Sub inlet 250 & 1000 micron screen net HDPE Lined secondary supply canal Module Biosecurity – Water treatment system (Control WSSV) Physical barrier for viral carriers – use 250 micron screen net Treatment Reservoirs ponds Chemical application – kill viral carriers. Apply crusticides Culture ponds Kill free water bore virus (aging) - dies in 72 hrs without host Treated water ready for use for culture (apply same procedure) Module Base Close Water System Basic (SOP) Procedure for Biosecurity (Summary) Parameters Closed Water Semi Closed Water Open Water Fill in Water Treatment (unit 1 & 2) and Culture ponds (Max. level > 120 cm) 1 - 45 All ponds/ Crustacide 0.5 – 1.0 ppm Chlorine 25-50 ppm Yes - approximately 5– 10 days All ponds minimum 3 (72 hours) days Yes – at all critical points: Main inlet, between TP units TP & Main TP or Supply canal. TP & CP No Within module only Started fill in to Treatment (unit 1 & 2) and Culture ponds (optimum level >100 cm) 46 – 90 Chlorine 25-50 ppm or whenever possible Started fill in to Treatment (unit 1 & 2 and Culture ponds (Max level > 120 cm). 91 - harvest Chlorine if possible Yes – approximately 5-10 days Minimum 3 days (72 hrs) Check if required Yes – at all critical points: Main inlet, between TP units; TP & Main TP or Supply canal. TP & CP Yes – at all critical points: Main inlet, between TP units; TP & Main TP or Supply canal. TP & CP Minimum (topping up only) Start open to outside Maximum Open to outside DOC (Day of Culture) Apply Crustacide/chlorine To Kill WSSV Carrier Bio assay Check toxicity Aging water To Kill WSSV in water Screening: 250 – 300 micron. Prevent carrier entering module Water exchange Water source Minimum 3 days (72 hrs) Basic of BFT in Shrimp Farming 1. 2. 3. 4. 5. 6. 7 8. 9. High stocking density - over 130 – 150 PL10/m2 High aeration – 28 to 32 HP/ha PWAs Paddle wheel position in ponds HDPE / Concrete lined ponds Grain (pellet) Molasses C&N ratio >15 Biofloc controled at <15 ml/L Expected production 20–25 MT/ha/crop 200 100 0 1 3 5 7 9 11 13 15 17 19 21 23 Feed & grain application and biofloc High aeration High density Biofloc Grain pellet Bioflocs Dark Vannamei Red Vannamei Environment AB Summary Salinity, Alkalinity (x10 ppm), Temp (am), Temp (pm) pH (am), pH (pm), Nitrite, TAN, DO (am), DO (pm) 9 35 8 30 7 25 6 20 5 4 15 3 10 2 5 1 0 0 May June July August September October November pH (am) pH (pm) Nitrite TAN Salinity Alkalinity (x10 ppm) DO (am) DO (pm) °C (am) °C (pm) December Arca Biru (BAB) farm performance Arca Biru Performance 20 (HDPE Full and Dyke Lined Pond) Growth 15 21.89 Metric ton (MT/Ha) 25.00 20.00 16.19 12.09 12.05 10 5 15.00 10.00 0 40 5.00 - Grams DoC Dyke 0.4 ha Dyke 0.8 ha Full 0.4 ha 50 Density 80 (Dike) 60 70 Density 110 (Full) 80 90 100 110 Density 130 Biofloc Full 0.8 ha PRODUCTION PERFORMANCE OF ARCA BIRU FARM Production Parameter No of Ponds PWA Energy (Hp) Stocking Density DOC (days) SR (%) MBW (gr) FCR (x) ADG (gr/day) Avg Harvest tonnage (kg) Production (Kg/Ha) Prod per power input (Kg/Hp) System/size/type Biofloc 0.4 ha HDPE Semi-Biofloc 0.8 ha HDPE Conven 0.8 ha HDPE Dyke 2 19 119 14 24 20 130 110 83 90 101 111 89.16 81.35 83.19 18.78 18.31 17.80 1.39 1.58 1.77 0.21 0.18 0.16 9,006 12,950 9,616 22,514 16,188 12,019 643 540 481 Nyan Taw, et.al. GAA March/April 2011 Arca Biru (BAB) Production Performance by Tonnage (1.0 Ha) 45 39 40 35 32 No of Ponds 30 25 21 20 19 20 17 16 15 18 18 18 18 18 19 19 19 20 19 16 14 15 10 5 0 0 1-2 2-3 3-4 4-5 5-6 6-7 7-8 8-9 Total pond 0 1 1 3 3 0 3 5 10 9 7 10 16 17 26 20 3 3 4 3 1 0 0 0 0 1 Full lining 0 0 0 0 0 0 0 0 0 0 1 1 2 0 3 3 2 0 4 3 1 0 0 0 0 1 Dyke lining 0 1 1 3 3 0 3 5 10 9 6 9 14 17 23 17 1 3 0 0 0 0 0 0 0 MBW 38.76 32.10 13.63 20.30 9-10 10-11 11-12 12-13 13-14 14-15 15-16 16-17 17-18 18-19 19-20 20-21 21-22 22-23 23-24 24-25 25-26 20.65 19.08 15.81 15.18 16.01 17.36 17.62 17.92 18.05 18.07 17.68 18.72 18.62 19.07 18.59 Tonnage range 0 20.00 Biofloc in shrimp farming 50,000 45,000 40,000 35,000 30,000 25,000 20,000 15,000 10,000 5,000 Kg 0 Belize, C America 2000 Lampung Indo 2003-05 Medan, Indo 2008 Commercial Kg/ha Java, Indo 2008 N Bali, Indo 2009 Max Record Kg/ha BAB Malaysia 2010 BAB Malaysia 2010 Trial Nyan Taw Shrimp farming Indonesia GAA Aug/Sep 2005 Acknowledgements The authors would like to sincerely thank Mr. Abu Bakar Ibrahim (CEO), Dr. Shahridan Faiez (former CEO) and Mr. Christopher Lim (COO), Blue Archipelago for their interest and support . The staff and members of Blue Archipelago, Malaysia for their diligence and hard work to make this work possible specially engineers Mr. Noorazam Ismail and Mr. Sukirno. Thank You Nyan Taw and Team 7 June 2011