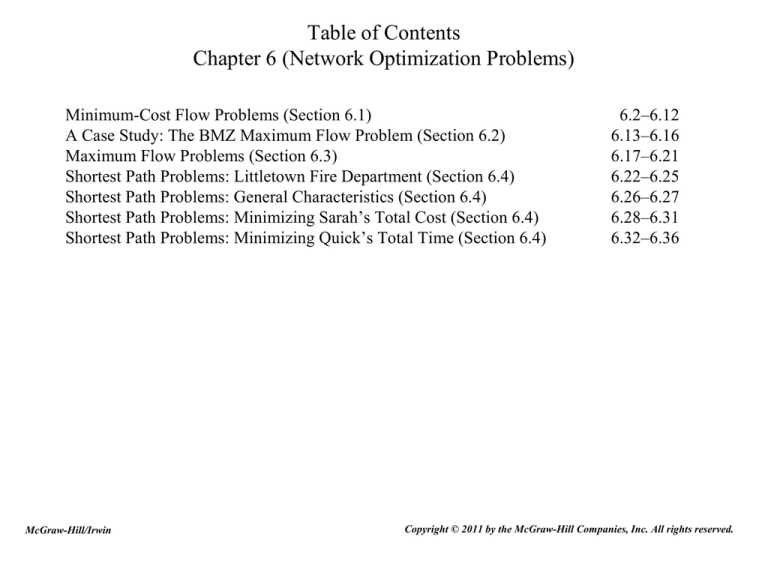

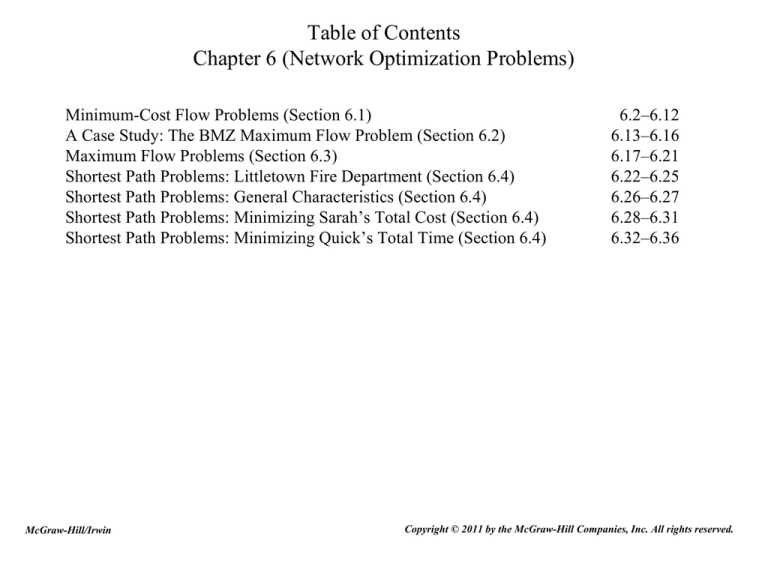

Table of Contents

Chapter 6 (Network Optimization Problems)

Minimum-Cost Flow Problems (Section 6.1)

A Case Study: The BMZ Maximum Flow Problem (Section 6.2)

Maximum Flow Problems (Section 6.3)

Shortest Path Problems: Littletown Fire Department (Section 6.4)

Shortest Path Problems: General Characteristics (Section 6.4)

Shortest Path Problems: Minimizing Sarah’s Total Cost (Section 6.4)

Shortest Path Problems: Minimizing Quick’s Total Time (Section 6.4)

McGraw-Hill/Irwin

6.2–6.12

6.13–6.16

6.17–6.21

6.22–6.25

6.26–6.27

6.28–6.31

6.32–6.36

Copyright © 2011 by the McGraw-Hill Companies, Inc. All rights reserved.

Distribution Unlimited Co. Problem

•

The Distribution Unlimited Co. has two factories producing a product that

needs to be shipped to two warehouses

–

–

–

–

Factory 1 produces 80 units.

Factory 2 produces 70 units.

Warehouse 1 needs 60 units.

Warehouse 2 needs 90 units.

•

There are rail links directly from Factory 1 to Warehouse 1 and Factory 2 to

Warehouse 2.

•

Independent truckers are available to ship up to 50 units from each factory to

the distribution center, and then 50 units from the distribution center to each

warehouse.

Question: How many units (truckloads) should be shipped along each

shipping lane?

6-2

The Distribution Network

80 units

produced

W1 60 units

needed

F1

DC

70 units

produced

F2

W2

90 units

needed

6-3

Data for Distribution Network

6-4

A Network Model

6-5

The Optimal Solution

[80]

[- 60]

(30)

F1

(50)

W1

(30)

[0]

DC

(30)

F2

[70]

(50)

(40)

W2

[- 90]

6-6

Terminology for Minimum-Cost Flow Problems

1. The model for any minimum-cost flow problem is represented by a network

with flow passing through it.

2. The circles in the network are called nodes.

3. Each node where the net amount of flow generated (outflow minus inflow) is a

fixed positive number is a supply node.

4. Each node where the net amount of flow generated is a fixed negative number

is a demand node.

5. Any node where the net amount of flow generated is fixed at zero is a

transshipment node. Having the amount of flow out of the node equal the

amount of flow into the node is referred to as conservation of flow.

6. The arrows in the network are called arcs.

7. The maximum amount of flow allowed through an arc is referred to as the

capacity of that arc.

6-7

Assumptions of a Minimum-Cost Flow Problem

1. At least one of the nodes is a supply node.

2. At least one of the other nodes is a demand node.

3. All the remaining nodes are transshipment nodes.

4. Flow through an arc is only allowed in the direction indicated by the

arrowhead, where the maximum amount of flow is given by the capacity of

that arc. (If flow can occur in both directions, this would be represented by a

pair of arcs pointing in opposite directions.)

5. The network has enough arcs with sufficient capacity to enable all the flow

generated at the supply nodes to reach all the demand nodes.

6. The cost of the flow through each arc is proportional to the amount of that

flow, where the cost per unit flow is known.

7. The objective is to minimize the total cost of sending the available supply

through the network to satisfy the given demand. (An alternative objective is

to maximize the total profit from doing this.)

6-8

Properties of Minimum-Cost Flow Problems

•

The Feasible Solutions Property: Under the previous assumptions, a

minimum-cost flow problem will have feasible solutions if and only if the sum

of the supplies from its supply nodes equals the sum of the demands at its

demand nodes.

•

The Integer Solutions Property: As long as all the supplies, demands, and

arc capacities have integer values, any minimum-cost flow problem with

feasible solutions is guaranteed to have an optimal solution with integer values

for all its flow quantities.

6-9

Spreadsheet Model

3

4

5

6

7

8

9

10

11

B

C

D

From

F1

F1

DC

DC

F2

F2

To

W1

DC

W1

W2

DC

W2

Ship

30

50

30

50

30

40

Total Cost

$110,000

E

<=

<=

<=

<=

F

G

Capacity

Unit Cost

$700

$300

$200

$400

$400

$900

50

50

50

50

H

I

J

Nodes Net Flow

F1

80

F2

70

DC

0

W1

-60

W2

-90

K

L

=

=

=

=

=

Supply/Demand

80

70

0

-60

-90

J

3

4

5

6

7

8

Net Flow

=SUMIF(From,I4,Ship)-SUMIF(To,I4,Ship)

=SUMIF(From,I5,Ship)-SUMIF(To,I5,Ship)

=SUMIF(From,I6,Ship)-SUMIF(To,I6,Ship)

=SUMIF(From,I7,Ship)-SUMIF(To,I7,Ship)

=SUMIF(From,I8,Ship)-SUMIF(To,I8,Ship)

6-10

The SUMIF Function

•

The SUMIF formula can be used to simplify the node flow constraints.

=SUMIF(Range A, x, Range B)

•

For each quantity in (Range A) that equals x, SUMIF sums the corresponding

entries in (Range B).

•

The net outflow (flow out – flow in) from node x is then

=SUMIF(“From labels”, x, “Flow”) – SUMIF(“To labels”, x, “Flow”)

6-11

Typical Applications of Minimum-Cost Flow Problems

Kind of

Application

Supply

Nodes

Transshipment

Nodes

Demand

Nodes

Operation of a

distribution network

Sources of goods

Intermediate storage

facilities

Customers

Solid waste

management

Sources of solid

waste

Processing facilities

Landfill locations

Operation of a

supply network

Vendors

Intermediate

warehouses

Processing facilities

Coordinating product

Plants

mixes at plants

Production of a

specific product

Market for a specific

product

Cash flow

management

Short-term

investment options

Needs for cash at a

specific time

Sources of cash at a

specific time

6-12

The BMZ Maximum Flow Problem

•

The BMZ Company is a European manufacturer of luxury automobiles. Its

exports to the United States are particularly important.

•

BMZ cars are becoming especially popular in California, so it is particularly

important to keep the Los Angeles center well supplied with replacement parts

for repairing these cars.

•

BMZ needs to execute a plan quickly for shipping as much as possible from

the main factory in Stuttgart, Germany to the distribution center in Los

Angeles over the next month.

•

The limiting factor on how much can be shipped is the limited capacity of the

company’s distribution network.

Question: How many units should be sent through each shipping lane to

maximize the total units flowing from Stuttgart to Los Angeles?

6-13

The BMZ Distribution Network

[60 unit s max.]

RO Rotte rdam

[50 unit s max.]

Ne w York NY

[80 unit s max.]

Ne w O rl e an s

LA

Los An gel e s

[70 unit s max]NO

{40 units max.]

ST S tu ttgart

[70 unit s max.]

Borde au x

[40 unit s max.]

BO

[50 unit s max.]

LI

Lis bon

[30 unit s max.]

6-14

A Network Model for BMZ

RO

[60]

[50]

NY

[80]

[40]

BO

LA

[70]

ST

[50]

[70]

NO

[40]

[30]

LI

6-15

Spreadsheet Model for BMZ

3

4

5

6

7

8

9

10

11

12

13

14

B

C

D

From

Stuttgart

Stuttgart

Stuttgart

Rotterdam

Bordeaux

Bordeaux

Lisbon

New Y ork

New Orleans

To

Rotterdam

Bordeaux

Lisbon

New Y ork

New Y ork

New Orleans

New Orleans

Los Angeles

Los Angeles

Ship

50

70

30

50

30

40

30

80

70

Maximum Flow

150

E

F

<=

<=

<=

<=

<=

<=

<=

<=

<=

Capacity

50

70

40

60

40

50

30

80

70

G

H

I

Nodes

Stuttgart

Rotterdam

Bordeaux

Lisbon

New Y ork

New Orleans

Los Angeles

Net Flow

150

0

0

0

0

0

-150

J

K

Supply/Demand

=

=

=

=

=

0

0

0

0

0

6-16

Assumptions of Maximum Flow Problems

1. All flow through the network originates at one node, called the source, and

terminates at one other node, called the sink. (The source and sink in the BMZ

problem are the factory and the distribution center, respectively.)

2. All the remaining nodes are transshipment nodes.

3. Flow through an arc is only allowed in the direction indicated by the

arrowhead, where the maximum amount of flow is given by the capacity of

that arc. At the source, all arcs point away from the node. At the sink, all arcs

point into the node.

4. The objective is to maximize the total amount of flow from the source to the

sink. This amount is measured in either of two equivalent ways, namely, either

the amount leaving the source or the amount entering the sink.

6-17

BMZ with Multiple Supply and Demand Points

•

BMZ has a second, smaller factory in Berlin.

•

The distribution center in Seattle has the capability of supplying parts to the

customers of the distribution center in Los Angeles when shortages occur at

the latter center.

Question: How many units should be sent through each shipping lane to

maximize the total units flowing from Stuttgart and Berlin to Los Angeles

and Seattle?

6-18

Network Model for The Expanded BMZ Problem

HA

[40]

[60]

BN

[30]

[20]

RO

SE

[40]

BE

[60]

[10]

LA

[20]

[50]

NY

[40]

[80]

BO

[70]

ST

[50]

[70]

NO

[40]

[30]

LI

6-19

Spreadsheet Model

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

B

C

D

From

Stuttgart

Stuttgart

Stuttgart

Berlin

Berlin

Rotterdam

Bordeaux

Bordeaux

Lisbon

Hamburg

Hamburg

New Orleans

New Y ork

New Y ork

Boston

Boston

To

Rotterdam

Bordeaux

Lisbon

Rotterdam

Hamburg

New Y ork

New Y ork

New Orleans

New Orleans

New Y ork

Boston

Los Angeles

Los Angeles

Seattle

Los Angeles

Seattle

Ship

40

70

30

20

60

60

30

40

30

30

30

70

80

40

10

20

Maximum Flow

220

E

F

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

<=

Capacity

50

70

40

20

60

60

40

50

30

30

40

70

80

40

10

20

G

H

I

Nodes

Stuttgart

Berlin

Hamburg

Rotterdam

Bordeaux

Lisbon

Boston

New Y ork

New Orleans

Los Angeles

Seattle

Net Flow

140

80

0

0

0

0

0

0

0

-160

-60

J

K

Supply/Demand

=

=

=

=

=

=

=

0

0

0

0

0

0

0

6-20

Some Applications of Maximum Flow Problems

1. Maximize the flow through a distribution network, as for BMZ.

2. Maximize the flow through a company’s supply network from its vendors to

its processing facilities.

3. Maximize the flow of oil through a system of pipelines.

4. Maximize the flow of water through a system of aqueducts.

5. Maximize the flow of vehicles through a transportation network.

6-21

Littletown Fire Department

•

Littletown is a small town in a rural area.

•

Its fire department serves a relatively large geographical area that includes

many farming communities.

•

Since there are numerous roads throughout the area, many possible routes may

be available for traveling to any given farming community.

Question: Which route from the fire station to a certain farming community

minimizes the total number of miles?

6-22

The Littletown Road System

8

6

A

1

3

6

Fire

Station

4

2

C

D

6

7

6

3

3

B

5

4

4

F

Farming

Communit y

G

5

E

2

4

H

7

6-23

The Network Representation

A

3

(Origin)

O

1

6

4

B

6

4

5

2

D

3

E

7

C

8

F

3

6

5

4

G

2

4

6

T

(Destinat ion)

7

H

6-24

Spreadsheet Model

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

B

C

D

From

Fire St.

Fire St.

Fire St.

A

A

B

B

B

B

C

C

D

D

E

E

E

E

F

F

G

G

G

H

H

To

A

B

C

B

D

A

C

D

E

B

E

E

F

D

F

G

H

G

Farm Com.

F

H

Farm Com.

G

Farm Com.

On Route

1

0

0

1

0

0

0

0

1

0

0

0

0

0

1

0

0

0

1

0

0

0

0

0

Total Distance

19

E

F

Distance

3

6

4

1

6

1

2

4

5

2

7

3

8

3

6

5

4

3

4

3

2

6

2

7

G

H

I

Nodes

Fire St.

A

B

C

D

E

F

G

H

Farm Com.

Net Flow

1

0

0

0

0

0

0

0

0

-1

J

K

=

=

=

=

=

=

=

=

=

=

Supply/Demand

1

0

0

0

0

0

0

0

0

-1

6-25

Assumptions of a Shortest Path Problem

1. You need to choose a path through the network that starts at a certain node,

called the origin, and ends at another certain node, called the destination.

2. The lines connecting certain pairs of nodes commonly are links (which allow

travel in either direction), although arcs (which only permit travel in one

direction) also are allowed.

3. Associated with each link (or arc) is a nonnegative number called its length.

(Be aware that the drawing of each link in the network typically makes no

effort to show its true length other than giving the correct number next to the

link.)

4. The objective is to find the shortest path (the path with the minimum total

length) from the origin to the destination.

6-26

Applications of Shortest Path Problems

1. Minimize the total distance traveled.

2. Minimize the total cost of a sequence of activities.

3. Minimize the total time of a sequence of activities.

6-27

Minimizing Total Cost: Sarah’s Car Fund

•

Sarah has just graduated from high school.

•

As a graduation present, her parents have given her a car fund of $21,000 to

help purchase and maintain a three-year-old used car for college.

•

Since operating and maintenance costs go up rapidly as the car ages, Sarah

may trade in her car on another three-year-old car one or more times during

the next three summers if it will minimize her total net cost. (At the end of the

four years of college, her parents will trade in the current used car on a new car

for Sarah.)

Question: When should Sarah trade in her car (if at all) during the next three

summers?

6-28

Sarah’s Cost Data

Operating and Maintenance Costs

for Ownership Year

Trade-in Value at End

of Ownership Year

Purchase

Price

1

2

3

4

1

2

3

4

$12,000

$2,000

$3,000

$4,500

$6,500

$8,500

$6,500

$4,500

$3,000

6-29

Shortest Path Formulation

25,000

17,000

10,500

10,500

(Origin) 0

5,500

1

5,500

2

5,500

3

5,500

4

(Destinat ion)

10,500

17,000

6-30

Spreadsheet Model

B

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Y ear

Y ear

Y ear

Y ear

1

2

3

4

From

Y ear 0

Y ear 0

Y ear 0

Y ear 0

Y ear 1

Y ear 1

Y ear 1

Y ear 2

Y ear 2

Y ear 3

C

D

E

Operating &

Maint. Cost

$2,000

$3,000

$4,500

$6,500

Trade-in Value

at End of Y ear

$8,500

$6,500

$4,500

$3,000

Purchase

Price

$12,000

On Route

0

1

0

0

0

0

0

0

1

0

Cost

$5,500

$10,500

$17,000

$25,000

$5,500

$10,500

$17,000

$5,500

$10,500

$5,500

To

Y ear

Y ear

Y ear

Y ear

Y ear

Y ear

Y ear

Y ear

Y ear

Y ear

1

2

3

4

2

3

4

3

4

4

Total Cost

F

G

H

Nodes Net Flow

Y ear 0

1

Y ear 1

0

Y ear 2

0

Y ear 3

0

Y ear 4

-1

I

J

=

=

=

=

=

Supply/Demand

1

0

0

0

-1

$21,000

6-31

Minimizing Total Time: Quick Company

•

The Quick Company has learned that a competitor is planning to come out

with a new kind of product with great sales potential.

•

Quick has been working on a similar product that had been scheduled to come

to market in 20 months.

•

Quick’s management wishes to rush the product out to meet the competition.

•

Each of four remaining phases can be conducted at a normal pace, at a priority

pace, or at crash level to expedite completion. However, the normal pace has

been ruled out as too slow for the last three phases.

•

$30 million is available for all four phases.

Question: At what pace should each of the four phases be conducted?

6-32

Time and Cost of the Four Phases

Remaining

Research

Development

Design of

Mfg. System

Initiate Production

and Distribution

Normal

5 months

—

—

—

Priority

4 months

3 months

5 months

2 months

Crash

2 months

2 months

3 months

1 month

Level

Remaining

Research

Development

Design of

Mfg. System

Initiate Production

and Distribution

Normal

$3 million

—

—

—

Priority

6 million

$6 million

$9 million

$3 million

Crash

9 million

9 million

12 million

6 million

Level

6-33

Shortest Path Formulation

,

0

1 h)

as

r

(C

2

5

3 ty) 2, 21(Priorit y)3, 12(Priorit y)4, 9

o ri

i

(C 3

r

P

(

ras

1, 27 2

h)

( Cr

a

s h)

2

5

5 al)

4, 6

2,

18

3,

9

m

)

(Priorit

y)

r

(Priorit

y)

y

t

o

3

i

r

(C 3

(N

io

r as

(Origin) 0, 30 4

1, 24 (Pr

(Priorit y) (C 2

h)

(C 2

ra

2

s h 2, 15 5

ra s

4, 3

3,

6

)

h)

(Priorit

y)

((P

riority)

3 ri ty ) (C 3

ras

1, 21 ri o

h)

(Cr (P2

ash

5

3, 3 2

4, 0

) 2, 12(Priorit

y)

(Priorit y)

0

ra

1 h)

s

(C

0

T

(Destinat ion)

1 s h)

ra

(C

0

6-34

Spreadsheet Model

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

B

C

D

From

(0, 30)

(0, 30)

(0, 30)

(1, 27)

(1, 27)

(1, 24)

(1, 24)

(1, 21)

(1, 21)

(2, 21)

(2, 21)

(2, 18)

(2, 18)

(2, 15)

(2, 15)

(2, 12)

(3, 12)

(3, 12)

(3, 9)

(3, 9)

(3, 6)

(3, 6)

(3, 3)

(4, 9)

(4, 6)

(4, 3)

(4, 0)

To

(1, 27)

(1, 24)

(1, 21)

(2, 21)

(2, 18)

(2, 18)

(2, 15)

(2, 15)

(2, 12)

(3, 12)

(3, 9)

(3, 9)

(3, 6)

(3, 6)

(3, 3)

(3, 3)

(4, 9)

(4, 6)

(4, 6)

(4, 3)

(4, 3)

(4, 0)

(4, 0)

(T)

(T)

(T)

(T)

On Route

0

0

1

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

0

1

0

0

0

1

Total Time

10

E

F

Time

5

4

2

3

2

3

2

3

2

5

3

5

3

5

3

5

2

1

2

1

2

1

2

0

0

0

0

G

H

I

J

K

Nodes

(0, 30)

(1, 27)

(1, 24)

(1, 21)

(2, 21)

(2, 18)

(2, 15)

(2, 12)

(3, 12)

(3, 9)

(3, 6)

(3, 3)

(4, 9)

(4, 6)

(4, 3)

(4, 0)

(T)

Net Flow

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-1

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Supply/Demand

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-1

6-35

The Optimal Solution

Phase

Level

Time

Cost

Remaining research

Crash

2 months

$9 million

Priority

3 months

6 million

Crash

3 months

12 million

Priority

2 months

3 million

10 months

$30 million

Development

Design of manufacturing system

Initiate production and distribution

Total

6-36