Document

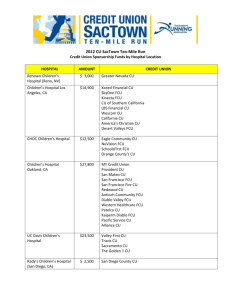

advertisement

SYSTEM SELLING BINDER WHY NOT HEAT PUMPS • • • • • COST TOO MUCH TO BUY COST TOO MUCH TO OPERATE COST TOO MUCH TO MAINTAIN TOO COMPLICATED TOO NOISY SOFTWARE • • • • LEEDS OPERATING COST CLIMASIZE SOUND ANALYZER WSHP INSTALLED COST Water Loop Heat Pump (May 2005) ft2 Tonnage WSHP Electrical Loop Piping Condensate drains Boiler Cooling tower Loop pumps Controls Other Total Cost per ton of Block Cooling load cost per ft2 (320 ft2) 320 100 Material Burden Total 130680 11880 11880 4680 31140 18360 6660 11880 22680 249840 51840 8640 17280 8640 6120 1800 1800 4320 10080 110520 182520 20520 29160 13320 37260 20160 8460 16200 32760 360360 3603.6 11.26 FOUR PIPE INSTALLED COST 4-Pipe Fan coil system-Reciprocating WCC (May 2005) ft2 320 Tonnage 100 FCU Electrical Piping Condensate drains Boiler Chiller Cooling tower pumps Controls Other Total Cost per ton of Block Cooling load cost per ft2 (320 ft2) Material Burden Total 95040 11880 47520 4680 36000 62640 18360 20520 11880 30780 339300 60480 8640 69120 8640 6840 1440 1800 5220 4320 16740 183240 155520 20520 116640 13320 42840 64080 20160 25740 16200 47520 522540 5225.4 16.33 SUMMARY Relative Installed costs Summary (May 2005) SYSTEM TYPE PTHP WLHP 2-Pipe FCU Reciprocating WCC 2-Pipe FCU Centrifugal WCC Unitary Rooftop VAV 4-Pipe FCU Reciprocating WCC 4-Pipe FCU Centrifugal WCC GLHP Relative Installed costs Cost/ton cost per ft2 0.9 3092.4 9.66 1 3603.6 11.26 1.06 3810.6 11.91 1.11 4001.4 12.50 1.11 3999.6 12.50 1.45 5225.4 16.33 1.50 5418 16.93 1.56 5607 17.52 Type of System GLHP 4-Pipe FCU Centrifugal WCC 4-Pipe FCU Reciprocating WCC Unitary Rooftop VAV 2-Pipe FCU Centrifugal WCC 2-Pipe FCU Reciprocating WCC WLHP PTHP May 2005 Relative installation costs RELATIVE INSTALLED COST May 2005 Relative installation costs 1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 ASHRAE MEDIAN LIFE WLHP ROOFTOP PTAC MARRIOTT PTAC CHILLERS 19 15 15 7 20 OPERATING COST CONSUMPTION-KW/SQ FT/YR 2 PIPE FC VAV ROOFTOP VAV CENTRAL PTAC PTHP WLHP 1.3 1.2 1.1 1.3 1.2 1.0 AIR COOLEDE CONDENSERS 27 % COIL EFFICIENCY LOSS 10.0 EER ERODED TO 7.3 IN 18 MONTHS CONDENSER FAN MOTOR FAILURE 15% PER YEAR SHORTENED COMPRESSOR LIFE MAINTENANCE COST 2 PIPE FC VAV ROOFTOP VAV CENTRAL PTAC PTHP WLHP 1.4 1.1 1.2 0.8 0.85 1.0 QUICK RULES OF THUMB 1. 2. 3. 4. 5. 6. AVERAGE SQ FT/TON AVERAGE CFM/SQ FT AVERAGE LIGHTING LOAD AVERAGE INSTALLED COST TENNANT FIT COST MAINTENANCE COST 300 1 2-3 W/FT $5-8/FT $2/FT WSHP $.10/FT/YR GEO .07 VAV .135 AIR/AIR .14 7. 8. HAVAC USES 45-55% OF ENERGY OF THIS AMOUNT COOLINGTOWER BOILER SYSTEM PUMP HEAT PUMPS 6% 23 24 48 QUICK SELECTION METHODS • • • • • • • • • • • • BUILDING SIZE USE 300 PER TON USE 2.5 GPM PER TON PUMP SELECTION TOWER SELECTION BOILER SELECTION VENTILATION PER LOCAL CODE 100,000 SQ FT 100,000/300=333 TONS 333 x 2.5=832 GPM USE 75 FT OF HEAD BHP=956 X 8.3 X 75/33000 X .75 EFF=24 HP USE WB PER ASHRAE LOCATION USE 90-101 DEGREES USE 956 GPM USE 50% DIVERSITY BTU=956 X 500 X3.5 DEG=1673,000 USE 1 CFM PER SQ FT IF RATE =15%=15000 CFM SOUND • • • • • • • UNITS CHANGES COMPRESSOR ISOLATION FAN ISOLATION CHASSIS ISOLATION MUFFLERS ROTARY AND SCROLL COMPRESSORS 410 A SOUND • NEW CERTIFIED SOUND LAB • CERTIFIED SOUND POWER DATA FACTORY VISITS NATIONAL REFERENCE JOB LIST BULETINS • • • • TECHNICAL COMPETITIVE MARKETING OTHERS