Stáhnout soubor

advertisement

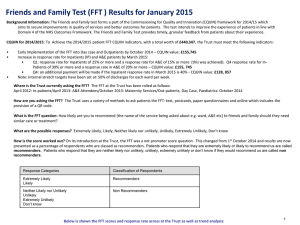

O metodě konečných prvků Lect_15.ppt FFT and FEM M. Okrouhlík Ústav termomechaniky, AV ČR, Praha Plzeň, 2010 Obsah • • • • • Terminologie Fourierova řada CFT, DFT a FFT Pár příkladů Mudrování o platnosti MKP výsledků Terminologie Fourierova řada, CFT, DFT a FFT • • • • Fourier series Continuous Fourier Transform Discrete Fourier Transform Fast Fourier Transform Fourierova řada, 20 členů T = Tmax = n * Timp, n = 2,4,8,16 Obdélníkový puls – CFT tři obdélníkové pulsy různé délky – různá normalizace C( ) = 2*abs(sin( T/2))/ -5 Amplitude spectrum 5 x 10 timp = 1e-5 timp = 2e-5 timp = 5e-5 4 3 2 1 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 5 x 10 C( )/T = 2*abs(sin( T/2))/( T) Amplitude spectrum 1 timp = 1e-5 timp = 2e-5 timp = 5e-5 0.8 0.6 0.4 0.2 0 0 f3 3 fft c3.m, fig1 0.2 0.4 0.6 0.8 1 frequency in Hz 1.2 1.4 1.6 1.8 2 5 x 10 FFT je způsob výpočtu DFT Základní vztahy_1 Sampling rate, vzorovací frekvence Continuous and sampled forms of a signal 20 15 10 5 0 -5 -10 -15 -20 0 5 10 15 20 25 30 35 40 30 35 40 Coarse sampling spoils the signal 20 15 10 5 0 -5 -10 -15 -20 0 5 continuous and sampled fig1 10 15 20 time 25 Základní vztahy_2 Je to vztah mezi číselnými hodnotami Pro diskusi o významu termínu power spectrum jsou následující důležité vztahy mean(y) = sum(y)/N Area = tmax*sum(y)/(N–1) = tmax*mean(y)*N/(N-1) ~ tmax*mean(y) první členy řad Y a pY Y(1) = mean(y) * N pY(1) = mean(y) * mean(y) * N c0 t final t initial i 0t P t e dt Pt dt Základní vztahy_3 FFT Obdélníkový puls a MPS (Fast Fourier Transform) (Matlab Power Spectrum) sampled signal 4 3 2 1 0 0 1 2 3 4 5 6 7 time [s] FFT spectrum - real part FFT spectrum - imaginary part 20 20 Nyquist 10 10 0 -10 0 0 10 20 30 40 50 -10 60 counter 0 10 20 30 40 50 60 counter FFT power spectrum 5 4 Nyquist 3 2 1 0 0 kkk c1 fig1 0.5 1 1.5 2 2.5 frequency [Hz] 3 3.5 4 4.5 5 Význam členů y(1) a Y(1) Normalization of FFT data Základní vztahy_4 Základní vztahy_5 Nyquistova frekvence závisí na tom, zda počet vzorků je sudý či lichý. Je-li počet vzorků velký, rozdíl nestojí za řeč. function [f, p_x, n_f] = power_spect_c2(t,x) % compute fft power spectrum for x signal in time domain % input % t ... time ..... t(i) ... i = 1 : N % time range ..... t = 0 : dt : tmax % x ... signal ... x(i) ... i = 1 : N % output %f frequency f(i) ..... i = 1 : NF % p_x complete fft power spectrum p_x(i) ... i = 1 : N % n_f ... Nyquist frequency % number of sampled points N = length(t); % dt .. time increment, assumed uniform dt = t(2) - t(1); % sampling frequency = sampling rate s_r = 1/dt; % Nyquist frequency n_f = 0.5*s_r; % is N odd or even? use the reminder function rm = rem(N,2); % calculate increment of frequencies and frequencies if rm == 0,, df = s_r/N; f = (0:N/2)*df; % N is even else df = s_r/(N-1); f = (0:(N-1)/2)*df; % N is odd end NF = length(f); % Fourier spectrum f_x = fft(x); % complete power spectrum p_x = f_x.*conj(f_x)/N; % the first half of the power spectrum p_x = p_x(1:NF); % end of power_spect_c2 Obdélníkový puls – CFT tři obdélníkové pulsy různé délky – různá normalizace C( ) = 2*abs(sin( T/2))/ -5 Amplitude spectrum 5 x 10 timp = 1e-5 timp = 2e-5 timp = 5e-5 4 3 2 1 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 5 x 10 C( )/T = 2*abs(sin( T/2))/( T) Amplitude spectrum 1 timp = 1e-5 timp = 2e-5 timp = 5e-5 0.8 0.6 0.4 0.2 0 0 f3 3 fft c3.m, fig1 0.2 0.4 0.6 0.8 1 frequency in Hz 1.2 1.4 1.6 1.8 2 5 x 10 CFT vs. FFT three different rectangular pulses, the same sampling and the same window time domain timp = 0.1 timp = 0.2 timp = 0.5 1 1 1 0.8 0.8 0.8 0.6 0.6 0.6 0.4 0.4 0.4 0.2 0.2 0.2 matlab power spectrum 0 0 0.2 0.4 0.6 0.8 time [s] 1 0 0 0.2 0.4 0.6 0.8 time [s] -4 x 10 1/dt 4 0.2 0.4 0.6 0.8 time [s] 1 -4 x 10 100 15 1/timp 3 10 50 2 5 1 0 0 0.5 1 1.5 2 0 0.5 1 1.5 2 0 20 20 20 10 10 10 1.5 frequency [Hz] 2 1.5 0 0 5 x 10 F3 3 fft c3.m, fig2 ... the same w indow and sampling rate, three different pulses 0.5 1 1.5 frequency [Hz] 2 5 x 10 2 x 10 30 1 1 5 30 0.5 0.5 x 10 x 10 0 0 5 30 0 0 20 5 0 0 x 10 5 mps/mean/timp 1 -4 0 0 0.5 1 1.5 frequency [Hz] 2 5 x 10 CFT vs. FFT the same rectangular pulse, the same sampling and three different windows rectangular pulse tmax = 2*timp tmax = 4*timp 1 1 1 0.8 0.8 0.8 0.6 0.6 0.6 0.4 0.4 0.4 0.2 0 0.2 mean1 = 0.5 0 0.2 0.4 0.6 0.8 time [s] 1 0 1.2 0 0.2 0.4 -4 x 10 0.6 0.8 time [s] 1 0 1.2 20 10 20 10 5 4 5 0 0 1 5 x 10 0.5 2 3 frequency [Hz] 4 5 1.2 -4 x 10 0 c03 = mean12 * N3 0 1 5 x 10 0.5 0.4 1 20 40 2 3 frequency [Hz] 0.6 0.8 time [s] Nyquist = 5000000 [Hz] 15 1 0.4 c02 = mean22 * N2 c01 = mean1 * N1 0 0.2 x 10 30 0 0 -4 40 2 60 mean3 = 0.125 Nyquist = 5000000 [Hz] 80 power spectrum 0.2 mean2 = 0.25 Nyquist = 5000000 [Hz] normalized power spectrum tmax = 8*timp 2 3 frequency [Hz] 4 2 3 frequency [Hz] 4 5 5 x 10 0.5 df2 0.4 0.4 df1 0.3 0.3 0.3 0.2 0.2 0.2 0.1 0.1 0.1 0 0 1 2 3 frequency [Hz] 4 5 5 x 10 0 0 1 2 3 frequency [Hz] 4 5 5 x 10 0 0 1 5 5 x 10 Fyzikální význam Denoting the discretized time evolution of reference pulse P P1 P2 Pn T we can express its 1 n mean value Pmean Pi and the approximate the area under the pulse n i 1 tfinal Pt dt by Pmean T . tinitial The physical meaning of the last expression is the mean impulse. The area under the pulse can also be expressed by means of the first term of the continuous Fourier’s transform, CFT [Doyle, 1997]. This is the term corresponding to zero-th frequency and has the form c0 Pt e i 0t dt t final Pt dt . t initial Pokud je tedy vstupní veličinou síla, pak power spectrum (výkonové) by se mělo nazývat momentum (hybnostní) spectrum Momentum - hybnost Four different input pulses and their average The correlation between ˆc0 and Pmean values is shown in the first column of subfigures in Fig. 12. They are plotted as functions of the pulse counter. Both of them are readily available at the time of experiment and bear information related to the total momentum since the impulse of the loading force is equal to the rate of momentum, i.e. P dt m dv . Observing these two quantities one can easily judge the magnitude of the total impulse of the loading force. The second couple of quantities that could be correlated (see the subfigures in the righthand side column of Fig. 12) are the Euclidean norm of the time history of the loading pulse n 2 and the square root of the total input energy. This follows from the fact P i i 1 that the energy is proportional to the quadratic form of displacements and velocities, i.e. qT Kq q T Mq and could also be expressed as proportional to the quadratic form of applied forces QT K1 Q Q T M1 Q T , where q, q are global arrays of displacements and velocities ‘measured’ at time tfinal , M, K are mass and stiffness matrices, T is the time interval during which the mean global loading vector, defined by Q 0 0 0 Pmean 0 0 0 T , is applied. So observing the norm value one can estimate amount of energy being delivered by the pulse to the mechanical system. T Tube with four spiral slots, coarse mesh, dimensions Four different meshes Comparison of FE and EXP data for axial strains in different locations C:\spiral_slot_2006_backup_from_2007_10_24\1_u_2007_december_changed_data\u_2007_data_from_urmas_march_2007\ToMila\plot_urmas_data_march_2007_c1, f6 -4 2 LOC1 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0 0.5 1 1.5 2 2.5 3 3.5 -4 -4 axial strain 2 x 10 LOC2 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0 0.5 1 1.5 2 2.5 3 time -4 2 3.5 -4 x 10 LOC3 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0 0.5 1 1.5 2 time 2.5 3 3.5 -4 x 10 Comparison of filtered FE and EXP data for axial strains in different locations C:\spiral_slot_2006_backup_from_2007_10_24\1_u_2007_december_changed_data\u_2007_data_from_urmas_march_2007\ToMila\plot_urmas_data_march_2007_c1, f5 -4 2 LOC1 - exp vs. FE 3D, NM - filtered to experimental frequency cutoff x 10 G1R90L, mesh1, medium striker for all figures urmas data march 2007 0 -2 experiment FE analysis, filtered -4 0 0.5 1 1.5 2 2.5 3 3.5 -4 x 10 -4 axial strain 2 LOC2 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis, filtered -4 0 0.5 1 1.5 2 2.5 3 time -4 2 3.5 -4 x 10 LOC3 - exp vs. FE 3D, NM x 10 0 dt = 1e-7; sr = 1/dt; nf = sr/2 = 5000000; rel cut off = 1/50 = 0.02 -2 abs cut off = nf*rel cut off = 100000 experiment FE analysis, filtered f order = 2; [b,a] = butter(f order,rel cut off) -4 0 0.5 1 1.5 2 time 2.5 3 3.5 -4 x 10 FE data were filtered by a filter having the same upper frequency as the experiment sampling frequency And this leads to a question. That is, up to which frequency limit is the FE approach trustworthy? We know that FE method is a model of continuum. Continuum – also a model – being based on the continuity hypothesis, disregards the corpuscular structure of matter. It is assumed that matter within the observed specimen is distributed continuously and its properties do not depend on the specimen size. Quantities describing the continuum behavior are expressed as piecewise continuous functions of time and space. It is known, see [2], that such a conceived continuum has no upper frequency limit. To find a ‘meaningful’ frequency limit of FE model, which is of discrete – not continuous – nature, one might pursue the following heuristic reasoning. Rule of thump 1mm corresponds to 1 MHz Easy to remember Imagine a uniform finite element mesh with a characteristic element size, say s . Trying to safely ‘grasp’ a harmonic component (having the wavelength ) by this element size we require that at least five-element length fits the wavelength. This leads to 5s . What is the frequency of this harmonics? Taking a typical wave speed value in steel of about c 5000m/s and realizing that cT and f 1/ T , we get the sought-after ‘frequency limit’ in the form f c /(5s) . For a one-millimeter element we 5000 1 10 6 Hz 1 MHz . Let’s call it the five-element frequency, denoting get f 5 0.001 it f 5elem in the text. Bathe recommends 10 here When looking for the upper frequency limit of a discrete approach to continuum problems, we could proceed as follows s 5s cT c 5000m/s f 1/ T f c /(5s) • Characteristic element size • Wavelength to be registered • How many elements into the wavelength • Wavelength to period relation • Wave velocity in steel • Frequency to period relation • The limit frequency • For 1 mm element we have 5000 f 110 6 Hz 1 MHz 5 0.001 Limits of continuum, FE analysis and experiment characteristic sizes and corresponding frequencies atom size austenite steel grain size 1 mm finite element 1 MHz level 1 GHz level FE analysis range from 0.1mm to 100mm maximum exp. sampling limit 100 MHz - 14 bits 8 10 6 frequency in [Mhz] 10 Where is the continuum limit? 4 10 2 10 10 MHz 0 10 -2 10 -10 10 -8 10 -6 10 size in [m] -4 10 -2 10 All considered material properties within the observed infinitesimal element are identical with those of a specimen of finite size 10 kHz -4 2 Back to our example LOC1 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0.5 0 1 2 1.5 2.5 3.5 3 -4 -4 axial strain 2 x 10 LOC2 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0.5 0 1 2 1.5 2.5 2 3.5 3 time -4 -4 x 10 LOC3 - exp vs. FE 3D, NM x 10 0 -2 experiment FE analysis -4 0 0.5 1 2 1.5 time 2.5 3 3.5 -4 x 10 Observing the original (or raw) FE signal in Fig. 4 we may notice its three significant characteristics. First, the negative peak representing the input rectangular pulse, as it was changed on its way from the loading face of the tube to the measurement location; second, the slow frequency variation of the tail of the signal and finally the high frequency components superimposed on the signal everywhere. To estimate the low frequencies, appearing in the signal, let’s consider the lowest frequency of the unsupported infinitely long thin shell of the radius r . In [21] there is 1 E 1 derived the formula f , which when applied to our case gives 2 r (1 )(1 2 ) the value of 93 kHz. Due to the corresponding mode of vibration, let’s call this frequency the lowest breathing frequency. The first eigenfrequency of an infinitely long thin-walled tube Breathing frequency The tube has the thickness h, which is substantially smaller than its radius r. The material constants are Young’s modulus E, density and the Poisson’s ratio . . Assuming that the symmetry, radial and circumferential axes are denoted x, y and z respectively, we can write xx 1 1 E yy 0 xy (1 )(1 2 ) 0 zz xx yy 0 0 xy (1 2 ) / 2 1 zz 0 0 Let’s assume that in this case only radial displacement u y is non-zero. Assume the free body diagram of the mass element whose elementary mass is dm rh d dz . The radial displacement evokes stresses zz acting on both sides of the element having the surface area hdz. The corresponding elementary forces are dP zz h dz . The equation of motion for the radial direction with the resultant of P-forces is dm uy 2 dP sin(d / 2) 0 . Furthermore zz u E (1 ) zz ; zz y ; sin(d / 2) d / 2. (1 )(1 2 ) r Assuming the harmonic motion in the form u y U eit and its second time derivative, substituting this and the previous relations into the equation of motion, and rearranging we get 1 E 1 . r (1 )(1 2 ) Zig-zag frequency The faster frequency appearing in time distributions of displacements and strains is called the zig-zag frequency in the text. For the zig-zag frequency estimation let’s pursue the following reasoning. The case we are dealing with is three-dimensional even if its axial dimension is predominant and the thickness of the tube is rather small comparing to its axial length. Also the applied loading is rather mild – meaning that the time length of the pulse is relatively long with respect to time needed for a wave to pass through the overall length of the tube. Still, in reality there is a fully 3D wave motion pattern appearing within the tube cross section that is dutifully detected by the FE modeling we are employing. According to Huygens’ Principle each point on the surface being hit by a wave is a source of two kinds of waves – the longitudinal and transversal (shear) waves, respectively. [3]. 2D wavefronts, Huygen’s principle Material points having been hit by primary wave become sources of both types of waves i.e. P and S transversal, shear, S-wave Von Schmidt wavefront primary, longitudinal, P-wave dp007 At the beginning of the loading process the frequencies of evoked waves can be crudely estimated the following way. Each type of wave, being emanated from the outer surface, propagates through the tube thickness, is reflected from the inner surface, and hits the outer surface after the time interval 2s 2s , tS , tL cL cT where the tube thickness is denoted by s . The process is repeated. The corresponding estimates of frequencies of S- and L-waves hitting the outer surface are 1 1 fS , f L . tL tS Considering the given geometry and material properties the numerical values for these frequencies are fS 0.54 MHz, f L 0.93 MHz. In the text we will call them zig-zag frequencies with attributes L (for longitudinal waves) and with S (for shear waves) respectively. Transfer function for mesh1. NM vs.CD. Limit frequencies. C:\miok_2007\spiral_slot_2006_backup_from_2007_10_24\axisym\mesh_refinement_medium_striker_nm\ check_data_10.m, f5 imput pulse 4 2.5 x 10 -5 x 10 radial NM axial NM radial CD axial CD 3 2 1.5 2 1 1 0.5 0 0 0 1 2 time 3 4 0 1 2 time -5 x 10 transfer function, input vs. rad. disp -10 6 mesh1, disp, corner node x 10 4 -5 x 10 NM CD breathing frequency zig-zag L frequency zig-zag S frequency FE limit frequency cons FE limit frequency diag 5elem frequency 4 2 0 0 3 0.5 1 1.5 2 2.5 3 frequency from 0 to Nyquist 3.5 4 4.5 5 6 x 10 Transfer functions for different meshes from 0 to Nyquist C:\miok_2007\spiral_slot_2006_backup_from_2007_10_24\axisym\mesh_refinement_medium_striker_nm\ check_data_10.m, f13 6 x 10 -10 axisym, corner, rad. disp, mesh1 3 NM CD breathing frequency zig-zag L frequency zig-zag S frequency FE limit frequency cons FE limit frequency diag 5elem limit frequency transfer function 5 4 3 2 1 0 0 1 2 3 4 x 10 transfer function 1.5 1 0.5 0 0 -5 NM CD breathing frequency zig-zag L frequency zig-zag S frequency FE limit frequency cons FE limit frequency diag 5elem limit frequency 1.5 1 0.5 0 0 2 4 6 8 6 NM CD breathing frequency zig-zag L frequency zig-zag S frequency FE limit frequency cons FE limit frequency diag 5elem limit frequency 1.2 1 0.8 0.6 0.4 0.2 2 7 10 x 10 x 10 x 10 axisym, corner, rad. disp, mesh2 2 axisym, corner, rad. disp, mesh3 0.5 1 1.5 frequency from 0 to Nyquist [Hz] -5 2.5 5 x 10 x 10 0 0 -5 6 axisym, corner, rad. disp, mesh4 NM CD breathing frequency zig-zag L frequency zig-zag S frequency FE limit frequency cons FE limit frequency diag 5elem limit frequency 1 2 3 frequency from 0 to Nyquist [Hz] 4 x 10 7 Transfer functions for different meshes from 0 to 2 MHz C:\miok_2007\spiral_slot_2006_backup_from_2007_10_24\axisym\mesh_refinement_medium_striker_nm\ check_data_10.m, f14 transfer function 4 x 10 -10 axisym, corner, rad. disp, mesh1 1 NM CD breathing frequency zig-zag L frequency zig-zag S frequency 3 2 -5 axisym, corner, rad. disp, mesh2 NM CD breathing frequency zig-zag L frequency zig-zag S frequency 0.8 0.6 0.4 1 0.2 0 0 0.5 1 1.5 2 x 10 1 transfer function x 10 x 10 0.8 0.6 -5 0 0 axisym, corner, rad. disp, mesh3 1 NM CD breathing frequency zig-zag L frequency zig-zag S frequency 0.6 0.2 0.2 2 x 10 x 10 0.8 0.4 0.5 1 1.5 frequency range from 0 to 2 MHz 1 1.5 6 2 x 10 0.4 0 0 0.5 6 0 0 -5 6 axisym, corner, rad. disp, mesh1 NM CD breathing frequency zig-zag L frequency zig-zag S frequency 0.5 1 1.5 frequency range from 0 to 2 MHz 2 x 10 6 Observing Fig. 7 one should notice the subsequent ‘convergence’ of CD and NM peaks within the zig-zag frequency interval. The natural explanation is that with the finer meshsize, and with the correspondingly smaller timestep, both methods operate in ‘good’ frequency intervals where their spatial and temporal discretization errors are minimized. The presented transfer spectra for four studied meshes show a distinct indication of the breathing and zig-zag frequencies, the ‘convergence’ of CD and NM responses, subsequent disappearance of ‘false’ CD responses and that the ‘dubious’ CD frequency peaks do not have their counterparts in NM responses. What remains to be compared is the ‘raw’ FE signal with that the frequencies higher than the five-element frequency were filtered out. The results for the ‘raw’ and filtered FE signals, for the mesh1 and the NM operator with consistent mass matrix, are presented in Fig. 8. FE raw signal compared to that in which the frequencies higher than five-element ones were filtered out. C:\spiral_slot_2006_backup_from_2007_10_24\1_u_2007_december_changed_data\u_2007_data_from_urmas_march_2007\ToMila\plot_urmas_data_march_2007_c1.m, f10 -4 1 LOC1 - FE 3D, mesh1, NM raw signal vs. filtered to FE 5elem cutoff x 10 axial strain 0 In future these results might be confirmed by a new and more sophisticated experiment having a lower observational threshold, a higher sampling rate and also a higher frequency amplifier cut-off . -1 -2 -3 FE analysis, filtered to 5elem cutoff FE analysis, raw data -4 0.6 0.7 0.8 0.9 1 time [s] 1.1 1.2 1.3 1.4 1.5 -4 x 10 Conclusions The FE analysis is a robust tool giving reliable results with a satisfactory engineering precision in standard tasks of continuum mechanics. Nevertheless, employing the FE method in cases on borders of their applicability is tricky and obtained results have to be treated with utmost care, since they might be profoundly influenced by intricacies of finite element technology. It should be emphasized, however, that testing the methods in the vicinity of borders of their applicability we do not want to discredit them, on the contrary, the more precise knowledge of their imperfections makes us – users – more confident in them.