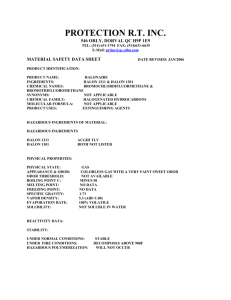

design, installation, testing, maintenance and safety

advertisement

CXS490 Chemical Extinguishing System Halocarbon Extinguishing System 1 Halons History 1910, carbon tetrachloride started to be used in a “glass grenade ("Pyrene") as an extinguishing agent. Due to its toxicity and a number of accidents related to its use, agent was prohibited as a fire extinguishant in the late 50's. 1930, (same "family"), methyl bromide (CH3Br) began use as extinguishing agent, but due to toxicity, its use as extinguishing agent has been discontinued. 2 Halons History Since about 1960, the two agents widely used Halon 1301 & Halon 1211 become more & more popular for applications until the Montreal Protocol (the international agreement to protect ozone layer) stopped production in 1994 of halons & later of other ozone depleting substances. 3 Halon Nomenclature System Naming Convention Halon system for naming halogenated hydrocarbons was devised by U.S. Army Corps of Engineers to provide a convenient and quick means of reference to candidate fire extinguishing agents. • First digit (number) represents number of carbon atoms in compound molecule; • Second digit represents number of fluorine atoms; • Third digit represents number of chlorine atoms; • Fourth digit represents number of bromine atoms; and • Fifth digit represents the number of iodine atoms. In this system, terminal digits, if equal to zero, are not expressed. 4 Halon Nomenclature System Naming Convention Halon 1301 CF3Br Halon 1211 CF2ClBr Halon 2402 C2F4Br2 F F C Br F Bromotrifluoromethane F Cl C Br F Bromochlorodifluoromethane F F Br C C Br F F Dibromotetrafluoroethane Discuss - Carbon Tetrachloride (CCl4) & Methyl bromide (CH3Br) 5 Halon 1301 Exposure Limits Human Exposure Original Concentration Guidelines: up to 7%: < 15 minutes exposure 7 to 10%: < 1 minute exposure (inhalation) 10 - 15%: < 30 seconds > 15%: prevent inhalation exposure Current Guidelines: NOAEL (Volume %) - 5% LOAEL (Volume %) - 7.5% Maximum Permitted Human Exposure for 5 minutes - 5% NOAEL - No Observable Adverse Effect Level LOAEL - Lowest Observed Adverse Effect Level 6 Halon 1301 Physical Properties Halon Properties Boiling Point °F Boiling Point °C SV Specific Volume Specific Volume - 71.95 - 58 k1 k2 2.2062 + .005046 x t 0.1478 + 0.00057 x t (Ft3/lbs) (t is °F) (M3/Kg) (t is °C) Vapour Pressure 199 psig @70°F 7 Halon Extinguishment Mechanism Extinguishing Mechanism The mechanism by which halons extinguish fire is not completely understood. However, it has been established that these products act by "breaking" the chemical flame chain reaction. Chain Breaking ~ 80 % Cooling ~ 20 % Secondary Primary 8 Halon 1301 Minimum Design Concentrations Halon Design Concentration Surface fires associated with the burning of solid material: 5% Other Fuels Fuels Acetone Benzene Ethylene Propane Methane Flame Extinguishment (% by Volume) 5.0 5.0 8.2 5.2 5.0 Inerting (% by volume) 7.6 5.0 13.2 6.7 7.7 Where the possibility of achieving an explosive concentration of the fuel exits, the “Inerting Concentration” must be used. 9 Discharge Duration 10 seconds To reduce increase of fire size & the resultant generation of HF and HBr True for Halocarbons & Halons 10 Halon 1301 and the Environment Montreal Protocol CFC's and halons destroy the stratospheric ozone that protects the earth from damaging ultraviolet radiation. An international agreement - the Montreal Protocol - was signed in September 1987 and was subsequently amended to require a phase-out of halon production in developed countries on January 1, 1994. This environmental problem has had a major impact on the use of halons. No substitute is available at present that offers a “drop in replacement” (same space and weight advantages) required for applications such as on-board aircraft systems or use within the crew compartments of military tactical vehicle. 11 Halon 1301 Design Standard Halon Standard NFPA 12A is the applicable design standard for Halon 1301 systems. 12 New Technology Halocarbon Agents New technology halogenated agents do not contain bromine or chlorine and are fluorocarbons. Fires extinguished by the cooling action required to fracture fluorocarbon molecule. Less efficient on a weight/space basis than halon 1301 and when exposed to fire they produce greater quantities of hydrogen fluoride (HF) than halon 1301 did. Stored in equipment that is similar to that used for halon 1301 systems, however flow rates are required to be slightly higher to accomplish discharge within 10 seconds. Where the possibility of achieving an explosive concentration of the fuel exits, the “Inerting Concentration” must be used 13 Halon Extinguishment Mechanism Halocarbon Extinguishing Mechanism The mechanism by which halocarbons extinguish fire is: Cooling Chain Breaking ~ 80 % ~ 20 % Primary Secondary 14 Halocarbon Extinguishing Agents HALOCARBON DESIGN FACTORS Specific Volume (Sv) Factors (*1) Generic Trade Name Name k1 k2 k1 k2 Imperial units Imperial units SI units SI units (ft3/lb) (ft3/lb) (m3/kg) (m3/kg) Standard (ISO) Halon 1301 Halon 1301 2.2062 0 .005046 0.1478 0.00057 HFC-23 (*1) FE-13 4.7302 0.010699 0.3164 0.0012 14520-10 HFC-125 (*1) FE-25 2.722 0.006376 0.1825 0.00073 14520-8 HFC-227ea (*1) FM 200 1.879775 0.0046625 0.1269 0.000513 14520-9 HFC-236fa (*1) FE-36 2.0978 0.00514 0.1413 0.0006 14520-11 FK-5-1-12 (*1) Novec-1230 0.9856 0.002441 0.0664 0.000274 14520-5 15 Halocarbon Extinguishing Agents - Design This table illustrates the various required design concentrations required (compared to halon 1301). HALOCARBON DESIGN FACTORS - Design Generic Name Trade Name Halon 1301 HFC-23 (*1) HFC-125 (*1) HFC-227ea (*1) HFC-236fa (*1) FK-5-1-12 (*1) Halon 1301 FE-13 FE-25 FM 200 FE-36 Novec-1230 Concentrations (*1) Minimum Minimum Class Class A DesignB Design Concentration Concentration Volume % (*2) Volume % (*2) 5 16.2 11.2 8.5 8.8 5.3 5 16.4 12.1 9.0 9.8 5.9 Inerting Concentration Methane/Air Volume % (#2) 4.9 22.2 8.8 - ISO Standard * 14520-10 14520-8 14520-9 14520-11 14520-5 16 Halocarbon Exposure HALOCARBON DESIGN FACTORS - Design Generic Name Trade Name Halon 1301 HFC-23 (*1) HFC-125 (*1) HFC-227ea (*1) HFC-236fa (*1) FK-5-1-12 (*1) Halon 1301 FE-13 FE-25 FM 200 FE-36 Novec-1230 Concentrations (*1) Maximum Permitted NOAEL LOAEL Human Exposure ISO Volume Volume % Concentration for 5 Standard % (*3) (*3) minutes (Occupied Areas) Volume % (*4) 5 7.5 5 * 30 >50 30 14520-10 7.5 10 10 14520-8 9 10.5 10.5 14520-9 10 15 12.5 14520-11 10 >10 10 14520-5 NOAEL - No Observable Adverse Effect Level LOAEL - Lowest Observed Adverse Effect Level All halocarbon agents have a maximum discharge time is 10 seconds to minimize unwanted production of hydrogen fluoride from flame contact by the agent. 17 Halocarbon Environmental New halocarbon agents do not pose a threat to Stratospheric Ozone Layer. Many have long atmospheric lifetimes and high global warming potential. All, except FK-5-1-12 are substances included in the Kyoto Protocol on Climate Change. HALOCARBON ENVIRONMENT AL FACTORS Global Ozone Atmospheric Warming Generic Name Trade Name Depletion Lifetime Potential Potential (years) (100 year) Halon 1301 Halon 1301 HFC-23 (*1) FE-13 HFC-125 (*1) FE-25 HFC-227ea (*1) FM 200 HFC-236fa (*1) FE-36 10 0 0 0 0 6,900 12,000 3,400 3,500 9,400 65 260 29 33 220 18 Halocarbon Technical Standards ISO 14520 and relevant sub-parts. ISO 14520 is not applicable to explosion suppression. ISO 14520 is not intended to indicate approval of the extinguishants listed therein by the appropriate authorities, as other extinguishants may be equally acceptable. 19 Halocarbon Technical Standards ISO 14520 specifies requirements and gives recommendations for the design, installation, testing, maintenance and safety of gaseous fire fighting systems in buildings, plant or other structures, and the characteristics of the various extinguishants and types of fire for which they are a suitable extinguishing medium. It covers total flooding systems primarily related to buildings, plant and other specific applications, utilizing electrically non-conducting gaseous fire extinguishants that do not leave a residue after discharge and for which there are sufficient data currently available to enable validation of performance and safety characteristics by an appropriate independent authority. 20 Halocarbon Technical Standards CO2 is not included as it is covered by other International Standards. 21 Halocarbon Technical Standards All Gaseous system fire suppression NFPA standards assume the use of the standard by someone experienced in that area. 22 Halocarbon Technical Standards - NFPA 2001 Agents in standard were introduced in response to international restrictions on the of certain halon fire extinguishing agents under the Montreal Protocol signed September 16, 1987, as amended. Standard is prepared for the use and guidance of those charged with purchasing, designing, installing, testing, inspecting, approving, listing, operating, and maintaining engineered (only) clean agent extinguishing systems, so that such equipment will function as intended throughout its life. 23 Halocarbon Technical Standards - NFPA 2001 Standard is intended to not restrict new technologies or alternate arrangements provided the level of safety prescribed by this standard is not lowered. NFPA 2001 does not provide all the necessary criteria for the implementation of a total flooding clean agent fire extinguishing system. Technology in this area is under constant development, and this will be reflected in revisions to this standard. The user of this standard must recognize the complexity of clean agent fire extinguishing systems. Therefore, the designer is cautioned that the standard is not a design handbook. 24 Halocarbon Technical Standards - NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems, is available to Seneca students by following the link to the Seneca Library from the My Seneca home page. 25 Halocarbon Systems General Requirements Halocarbon extinguishing systems are generally of the total flooding type. The commonly used halocarbons vapourize and mix with air very efficiently making them ideal total flooding agents. However these same characteristics make them generally unsuitable for use in local application type systems. 26 Halocarbon Systems General Requirements Total flooding halocarbon systems Total flooding systems may be used where there is a fixed enclosure about the hazard that is adequate to enable the required concentration to be built up and maintained for the required period of time to ensure the effective extinguishment of the fire. 27 Halocarbon Systems General Requirements Two types: 1. Modular systems (agent storage at point of discharge) Usually employs spherical containers connected to a maximum of four nozzles by short length of pipe. Often use explosive squibs for agent release (for valve opening). Different sizes of containers may be used in a single hazard 2. Central Storage Piped Systems Uses cylinders of equal size, containing equal weight of halon. These cylinders are piped to a manifold, with check valve at each manifold inlet connection. 28 Design of Halocarbon Systems The following elements have to be taken into account in the design of a halocarbon system: (refer to NFPA 12A for halon 1301 and NFPA 2001 or ISO 14520 for new technology halocarbon extinguishing systems) 1. Configuration of the hazard: dimensions (area, height, volume) of the hazard, nature of the separation before the risk and the surroundings areas. Volume used as a based for the computation of the quantity of agent, the nature of the enclosure will determine the extent of the protection (all areas that may be involved in a single fire incident must be simultaneously protected) 29 Design of Halocarbon Systems 2. Hazard ventilation: ventilation systems should be automatically shut down upon system actuation. 3. Hazard fuels : fuel involved in the hazard must be identified in order to determine the minimum required concentration. 30 Design of Halocarbon Systems 4. Hazard temperature range: From a given quantity of agent, the concentration that will be achieved in a given volume will vary with temperature in this volume. The lowest temperature is used to calculate minimum amount of agent needed to obtain the required concentration. The highest hazard temperature is used to verify that the maximum possible concentration that could be obtained is still acceptable for personnel safety. 31 Design of Halocarbon Systems 5. Specific Volume: The specific volume is calculated using the following formula: Sv units are m3/kg or ft3/lb T is temperature in OC or OF 32 Design of Halocarbon Systems 6. Agent quantity: The required agent quantity is calculated using the following mass formula: Mass flooding formula: where WLT = weight of halon V = enclosure volume C = Concentration SvLT = specific volume 33 Design of Halocarbon Systems 7. Agent Concentration: The resulting agent concentration calculated using the calculated weight from lowest temperature and the specific volume from highest temperature. NOT REQUIRED IF NO TEMPERATURE VARIATION! where C = Concentration WLT = weight of halon V = enclosure volume SvHT = specific volume 34 Design of Halocarbon Systems 8. Maximum discharge time : 10 seconds 9. Size of piping, # of nozzles, etc.: according to manufacturers' listed manual & computerized calculation programs 35 Design of Halocarbon Systems 10. Detection and control: A) Computer Rooms, Control Rooms, Telecommunications Facilities, Transformer vaults, etc. Facilities often utilize high air change rates using conditioned air. High air flow rates and chilled fresh air make it difficult to utilize heat detection as the sole means of fire detection to cause release of the halon. More often smoke detection devices are used. 36 Design of Halocarbon Systems In some cases, alarm from one such device will provide warning to occupants and cause shut-down of air handling systems. Alarm from a second device of the same or similar type results in automatic release of halocarbon. In other cases, heat detectors are used as a second stage detection means and automatic release only occurs when a heat detection device has responded. 37 Design of Halocarbon Systems Abort switches, when used, should be of “dead-man” type and installed only within the protected area. Manual pull stations should always be capable of overriding operation of abort stations. One manual release station should be located outside of the protected enclosure. 38 Design of Halocarbon Systems B) Hazards that include flammable liquids or gases Detection devices should be of either the explosion proof type or be intrinsically safe. Heat detection devices or optical flame detection type devices are most often used for fire detection in these applications. 39 Design of Halocarbon Systems It is not necessary that the control equipment and halon system be of the same manufacturer, however, both the NFPA 12A standard and the NFPA 2001 standard requires that the control equipment and releasing devices are compatible and that evidence of compatibility is provided. 40 Halocarbon Calculation Space with dimensions of 11.43 m long by 10.69 m wide by 2.72 m high is to be protected by Novec 1230. The operating temperature range is 10 to 40OC. Determine the required amount of agent and whether it is safe. 41 Halocarbon Calculation Determine necessary data input for agent k1 k2 c NOAEL LOAEL 5 Minute Exposure 0.0664 = 0.000274 = 5.3 % = 10 = >10 = 10 = (p 14) (p14) (p 15) (p 16) (p 16) (p16) 42 Halocarbon Calculation Weight 43 Halocarbon Calculation Concentration Is it safe? Yes (why?). Less than the 10% (NOAEL & 5 minute human exposure)! 44 Design of Halocarbon Systems Plans shall be to an indicated scale and reproducible. Sufficient detail to enable an evaluation of hazard and the effectiveness of system. They shall show a detail of the material involved in the hazard enclosure. 45 Design of Halocarbon Systems Plan Details of system shall include: • • • • • • • • • information and calculations on amount of halon 1301 container storage pressure, internal volume of the container(s) , location type and flow rate of each nozzle (including equivalent orifice area) location, size and equivalent length of pipe, fittings and hose location of the storage containers location and function of detection devices Auxiliary equipment and Electrical circuitry (if used). 46 Design of Halocarbon Systems Acceptance Test For new technology halocarbon agents refer to either For halon 1301 Refer to NFPA 2001 or ISO 14520. NFPA 12A. 47 Maintenance of Halocarbon Systems Inspection & Testing Annual: Complete inspection of system & non-destructive test Semi-Annual: Check agent quantity and pressure Every 5 Years: Hydrostatic test of all hoses Frequency Approved schedule level: Visual inspection It is also important to identify any change to the protected space, such as, reconfigured layout, added ventilation, etc. to ensure that installed system remains adequate for protected 48 space.