Lecture 18-19

advertisement

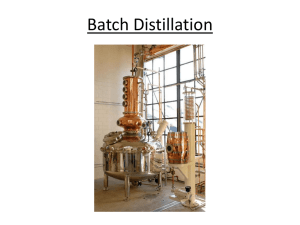

Unit Operations Lecture 19 7 Nov 2012 1 Overview •Review rigorous methods / RADFRAC • Multicomponent systems: o Residue curves o DSTWU / RADFRAC o Rules of thumb • Complex (Enhanced) distillation • Column internals • Batch distillation 2 Distillation Heuristics (Rules of Thumb) • Remove corrosive, dangerous, and reactive components first • Don’t use distillation if LK-HK < ~1.05 to 1.10 • Do easy separations first ( large). • Next split / separation / remove components in excess, then most volatile components (trying to minimize size of downstream columns). • Try to do most difficult separations as binary and last (taller columns will have smaller diameter. • Remove products and recycle streams as distillates (rust & heavy contaminates can accumulate in bottoms). • Whatever you add you normally have to remove at some point. 3 Distillation Heuristics (Turton) 4 Distillation Heuristics (Turton) 5 Distillation Heuristics (Turton) 6 Distillation Heuristics (Turton) 7 Variety of Phase Diagrams Stichlmair & Fair (1998) 8 Complex or Enhanced Distillation Ethanol – Water Binary (1.013 bar): 9 Complex Distillation Ethanol – Water Binary (1.013 bar): 10 Extractive Distillation EtOH H2O Ethylene Glycol 11 Extractive Distillation Solvent: • Lower volatility than feed mixture • Add above the feed stage • Add few trays below the top stage • No azeotrope formed with other components • Should interact differently with other components • Typically add 1:1 with feed (molar basis) 12 Unit Operations Lecture 20 09 Nov 2012 13 Overview •Review rigorous methods / RADFRAC • Multicomponent systems: o Residue curves o DSTWU / RADFRAC o Rules of thumb • Complex (Enhanced) distillation • Column internals • Batch distillation 14 Azeotropic Distillation Perry’s 8th ed. 15 Azeotropic Distillation Water with (binary system at atmospheric P): • methanol - no azeotrope • ethanol - azeotrope • propanol - azeotrope In-class exercise: • using Aspen Plus, explore if we can use distillation to separate the binary mixture of water and n-butanol. 16 Heterogeneous Azeotropic Distillation VLLE (NRTL) 17 Heterogeneous Azeotropic Distillation Perry’s 8th ed. 18 Residue Curve Maps 19 Complex Multicomponent Systems 20 Pressure Swing Distillation 21 Pressure Swing Distillation 22 Complex or Enhanced Distillation • Extractive Distillation o Higher boiling solvent o Enters near top of column o Interacts with other components to affect volatility or activity coefficients • Homogeneous Azeotropic Distillation o Add entrainer that forms min/max boiling point AZ w/ 1 or more of feed compds o Added near top or bottom, depending upon if AZ is min or max BP • Heterogeneous Azeotropic Distillation o Add entrainer to form min BP heterogeneous azeotrope (EtOH-H2O + benzene) • Pressure – Swing Distillation o For pressure sensitive azeotropes and distillation boundaries • Salt Distillation o Alter relative volatilities of feed compds by dissolving a soluble ionic salt into the reflux • Steam Distillation o Steam is added to reduce temperature of distilling organic mixture • Reactive Distillation o add reactant &/or catalyst to cause a reversible/selective reaction with one of the feed components o Reaction and distillation occur in same vessel 23 Column Internals 24 Column Internals 25 Column Internals 26 Column Internals 27 Column Internals Jaeger Product Bull. 400-09 28 Column Internals 29 Random and Structured Packing 30 Packed Columns (Distillation) • Usually for small diameter columns o Usually more economical for columns < ~75 cm (2.5 ft) o Lower pressure drop than trayed columns o Good for vacuum operations • Wide choice of packing materials (random or structured) 31 Column Internals 32 Packed Columns (Distillation) • Column diamter o Dcol/Dpacking ~ 8 – 12 (rule of thumb) o If Dcol/Dpacking > ~40, watch for channeling o Sized based usually on approach to flooding or acceptable pressure drop • Packing height HETP H packing N TH packing height number theoretica l stages 33 Trayed Columns (Diameter) • Chap 10 (p 314, Wankat) “Fair’s Procedure” o Considers entrainment flooding (most freq.) o Downcomer flooding (sometimes) – need different procedure o Downcomer flooding rare if (1- f) ≥ 10% • Used in AspenPlus Dia f V 1 2 , 1 , 1 frac * u flood James R. Fair (1920 -2010) tray Acs fraction available u flood flooding vapor velocity for vapor flow ft s frac fractional approach to flooding velocity 34 Trayed Columns (Diameter) • Plate spacing (selected for maintenance, performance). Typ: o 12 – 16” for Dia < 5’ o 24” larger columns • Calc Dia & round up to nearest ½ foot (USA) o 2.5’ minimum dia. o If < 2.5’ consider packed tower u flood C sb , f 20 0 .2 L V V surface tension C sb , f capacity dyne cm factor 35 Overview • Questions from last week?? • Review rigorous methods / RADFRAC • Multicomponent systems: o Residue curves o DSTWU / RADFRAC o Rules of thumb • Complex (Enhanced) distillation • Column internals • Batch distillation 36 Batch (Rayleigh) Distillation • Usually for small capacity systems • 1 column handle multi”campaigns” • Produce sample new products • Batch upstream processes • Feed contains solids/foulants Seader & Henley (2006) W ln Wo x xo dx yx where: Material Balance: leads to Rayleigh Equation x o x F mole fraction of initial charge W o F initial charge [moles ] 37 Batch (Rayleigh) Distillation W ln Wo x xo dx yx a) P = constant; K = f(T) only W ln Wo x 1 K 1 ln x o b) Binary with = constant 1 x 1 xo Wo ln ln ln 1 x W 1 x o c) y = K x ; but K = f(T,x) Solve graphically or numerically 38 Multistage Batch Distillation Seader & Henley (2006) Modes of operation: • Constant reflux rate or ratio • xD varies with time • easily implemented (flow sensors) • Relatively simple and cost effective • Constant distillate composition • R or D varies with time • Requires fast response composition sensors • Sensors might not be available or only justified for larger batch systems • Optimal control mode • xD and R varied with time • Designed to: Minimize operation time Maximize amount of distillate Maximize profit • More complex control scheme 39 Multistage Batch Distillation Removing volatile impurities. Flexible, multi-purpose system Seader & Henley (2006) 40 Questions? 41 42 43 Go Over Homework: 44