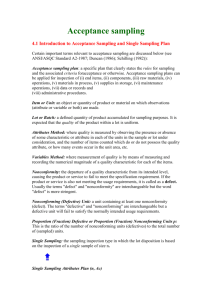

ACCEPTANCE SAMPLING

advertisement

BPT2423 – STATISTICAL PROCESS CONTROL Fundamental Concepts Types of Sampling Plans Single, Double, Multiple and Sequential Statistical Aspects Lot-By-Lot Acceptance Sampling Plans for Attributes Acceptance Sampling Plans For : Continuous Production Variables Know the advantages and disadvantages of sampling Understand the types of sampling plans and selection factors Determine the Operation Characteristic (OC) curve for a single sampling plan and the properties Lot-by-lot acceptance sampling by attributes is the most common type of sampling A predetermined number of units (sample) from each lot is inspected by attributes If the number of nonconforming units is less than the prescribed minimum, the lot is accepted; if not, the lot is not accepted Acceptance sampling can be used either for the number of nonconforming units or for nonconformities per unit Example : Lot size, N = 9000 Sample size, n = 300 Acceptance number, c = 2 Acceptance sampling is most likely to be used in one of five situations: 1. When the test is destructive, sampling is necessary; otherwise, all of the units will be destroyed by testing 2. When the cost of 100% inspection is high in relation to the cost of passing a nonconforming unit 3. When there are many similar units to be inspected; with manual inspection, fatigue and boredom cause a higher percentage of nonconforming material to be passed than would occur on the average using a sampling plan 4. When information concerning producer’s quality, such as X-Bar and R, p or c charts and Cpk is not available 5. When automated inspection is not available Disadvantages Advantages More economical (fewer inspectors and less handling) Upgrades the inspection job (piece-by-piece to lotby-lot) Applies to destructive testing Stronger motivation for improvement (entire lots are not accepted rather than the return of a few nonconforming units) Certain risks of not accepting conforming lots and accepting nonconforming lots More time and effort is devoted to planning and documentation Less information is provided about the product There is no assurance that the entire lot conforms to specifications Lot Formation can influence the effectiveness of the sampling plan: i. ii. Lots should be homogeneous Lots should be as large as possible The sample units selected for inspection should be representative of the entire lot – random sampling There are a number of courses of action that can be taken on the non-accepted lots: Passed to the production facilities and the nonconforming units sorted by production personnel b. Rectified at the consumer’s plant by personnel from either the producer’s or the consumer’s plant c. Returned to the producer for rectification a. Single – one sample is taken from the lot and a decision to accept or not accept the lot is made based on the inspection results of that sample Double – on the initial sample, a decision, based on the inspection results, is made whether: To accept the lot Not to accept the lot To take another sample If the quality is very good, the lot is accepted on the first sample and a second sample is not taken; if the quality is very poor, the lot is not accepted on the first sample and a second sample is not taken Only when the quality level is neither very good nor very bad is a second sample taken Multiple – is a continuation of double sampling in that three, four, five or as many samples as desired can be established. Sample sizes are much smaller Sequential – items are sampled and inspected one after another. A cumulative record is maintained and a decision is made to accept or not accept the lot as soon as there is sufficient cumulative evidence Remarks: All four types of sampling plans can give the same results. Thus, the type of plan for a particular unit is based on factors other than effectiveness These factor are simplicity, administrative costs, quality information, number of units inspected and psychological impact Operation Characteristic (OC) Curve for Single Sampling Plans In judging a particular sampling plan, it is desirable to know the probability that a lot submitted with a certain percent nonconforming, 100po , will be accepted – the OC curve will provide this information When the percent nonconforming is low, the probability of the lot being accepted is large and decreases as the percent nonconforming increases In graphing the curve with the variables 100Pa (percent of lots accepted) and 100po (percent nonconforming), one value, 100po , will be assumed and the other calculated Construction of an OC Curve 1. Assume po value 2. Calculate npo value 3. Attain Pa values from the Poisson table using the applicable c and npo values 4. Plot point (100po , 100Pa) 5. Repeat 1,2,3 and 4 until a smooth curve is obtained OC Curve for the Single Sampling Plan Calculation: OC Curve Properties Acceptance sampling plans with similar properties can give different Operation Characteristic (OC) curve: Sample size as a fixed percentage of lot size Fixed sample size OC Curve Properties (cont.) As sample size increase, the curve becomes steeper As the acceptance number decrease, the curve becomes steeper Consumer-Producer Relationship There is a conflicting interest between the consumer and the producer when using acceptance sampling Ideal OC curve that is a vertical line can satisfy both – can be achieved only with 100% inspection Sampling carries risks of not accepting lots that are acceptable and of accepting lots that are unacceptable Acceptance Quality Limit (AQL) “Is the quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling. It is a reference point on the OC curve and is not meant to convey to the producer that any percent nonconforming is acceptable. It is a statistical term and is not meant to be used by the general public” Consumer-Producer Relationship (cont.) 1. Producer’s Risk Represented by the symbol α, is the probability of non acceptance of a conforming lot This risk is frequently given as 0.05, but it can range from 0.001 to 0.10 or more It cannot be located on an OC curve unless specified in terms of the probability of acceptance This conversion is accomplished by subtracting from 1 Thus, Pa = 1 – α and for α = 0.05, Pa = 0.95 Consumer-Producer Relationship (cont.) Limiting Quality (LQ) “Is the percent nonconforming in a lot or batch for which, for acceptance sampling purposes, the consumer wishes the probability of acceptance to be low” 2. Consumer’s Risk Represented by the symbol β, is the probability of acceptance of a nonconforming lot This risk is frequently given as 0.10 Consumer-Producer Relationship (cont.) Example: AQL = 0.7% There are 0.7% nonconforming will have a non-acceptance probability of 5% or in other words; 1 out of 20 lots that are 0.7% nonconforming will not be accepted by the sampling plan LQ = 2.6% There are 2.6% nonconforming will have a 10% chance of being accepted or in other words; 1 out of 10 lots that are 2.6% nonconforming will be accepted by this sampling plan Attributes Was first devised in 1942 by a group of engineers at Bell Telephone Laboratories for use by the US government It was designated JAN-STD-105 and adopted by the ISO and designated ISO/DIS-2859 Have been revised 5 times (MIL-STD-105E) and modified by American Society for Quality (ASQ) under the designation ANSI/ASQ Z1.4 – all tables and procedures remain unchanged Attributes (cont.) Continuous Production Variables