powerpoint

advertisement

Combining Linear Programming

Based Decomposition Techniques

with Constraint Programming

Menkes van den Briel

Member of Research Staff

NICTA and ANU

menkes@nicta.com.au

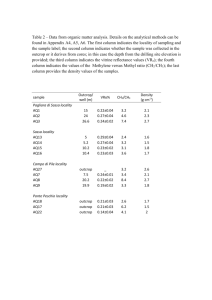

CP-based column generation

Application

Reference

Urban transit

crew

management

T.H. Yunes., A.V. Moura, C.C. de Souza. Solving very large crew scheduling problems to optimality.

Proceedings of ACM symposium on Applied Computing, pages 446-451, 2000.

T.H. Yunes., A.V. Moura, C.C. de Souza. Hybrid column generation approaches for urban transit

crew management problems. Transportation Science 39(2):273-288, 2005.

Travelling

tournament

K. Easton, G.L. Nemhauser, and M.A. Trick. Solving the travelling tournament problem: A combined

integer programming and constraint programming approach. Proceedings of Practice and Theory of

Automated Timetabling, volume 2740 of Lecture Notes in Computer Science, pages 100-112.

Springer, 2002.

Two-dimensional

bin packing

D. Pisinger, M. Sigurd. Using decomposition techniques and constraint programming for solving the

two-dimensional bin-packing problem. Journal on Computing 19(1):36-51, 2007.

Graph coloring

S. Gualandi. Enhancing constraint programming-based column generation for integer programs.

PhD thesis, Politechnico di Milano, 2008.

Constrained

cutting stock

T. Fahle, M. Sellmann. Cost based filtering for the constrained knapsack problem. Annals of

Operations Research 115(1):73-93, 2002.

Employee

timetabling

S. Demassey, G. Pesant, L.M. Rousseau. A cost-regular based hybrid column generation approach.

Constraints 11(4):315-333, 2006.

Wireless mesh

networks

A. Capone, G. Carello, I. Filippini, S. Gualandi, F. Malucelli. Solving a resource allocation problem in

wireless mess networks: A comparison between a CP-based and a classical column generation.

Networks 55(3):221-233, 2010.

Multi-machine

scheduling

R. Sadykov, L.A. Wolsey. Integer programming and constraint programming in solving a

multimachine assignment scheduling problem with deadlines and release dates. Journal on

Computing 18(2):209-217, 2006.

CP-based column generation

Application

Reference

Airline crew

assignment

U. Junker, S.E. Karisch, N. Kohl, B. Vaaben, T. Fahle, M. Sellmann. A framework for constraint

programming based column generation. Proceedings of Principles and Practice of Constraint

Programming, volume 1713 of Lecture Notes in Computer Science, pages 261-274, 1999.

T. Fahle, U. Junker, S.E. Karisch, N. Kohl, M. Sellmann, B. Vaaben. Constraint programming based

column generation for crew assignment. Journal of Hueristics 8(1):59-81, 2002.

M. Sellmann, K. Zervoudakis, P. Stamatopoulos, T. Fahle. Crew assignment via constraint

programming: integrating column generation and heuristic tree search. Annals of Operations

Research 115(1):207-225, 2002.

Vehicle routing

with time windows

L.M. Rousseau. Stabilization issues for constraint programming based column generation.

Proceedings of Integration of AI and OR techniques in CP for Combinatorial Optimization, volume

3011 of Lecture notes in Computer Science, pages 402-408. Springer, 2004.

L.M. Rousseau, M. Gendreau, G. Pesant, F. Focacci. Solving VRPTWs with constraint programming

based column generation. Annals of Operations Research 130(1):199-216, 2004.

CP-based Benders decomposition

Application

Reference

Parallel machine

scheduling

V. Jain, I.E. Grossmann. Algorithms for hybrid MILP/CP models for a class of optimization problems.

INFORMS Journal on Computing 13(4):258-276, 2001.

Polypropylene

batch scheduling

C. Timpe. Solving planning and scheduling problems with combined integer and constraint

programming. OR Spectrum 24(4):431-448, 2002.

Call center

scheduling

T. Benoist, E. Gaudin, B. Rottembourg. Constraint programming contribution to Benders

decomposition: A case study. Principles and Practice of Constraint Programming, volume 2470 of

Lecture Notes in Computer Science, pages 603-617. Springer, 2002.

Multi-machine

scheduling

J.N. Hooker. A hybrid method for planning and scheduling. Principles and Practice of Constraint

Programming, volume 3258 of Lecture Notes in Computer Science, pages 305-316. Springer, 2004.

J.N. Hooker. Planning and scheduling to minimize tardiness. Principles and Practice of Constraint

Programming, volume 3709 of Lecture Notes in Computer Science, pages 314-327. Springer, 2005.

CP versus IP

CP

IP

Variables

Finite domain

Continuous,

Binary, Integer

Constraints

Symbolic:

alldifferent

cumulative

Linear,

algebraic:

(+, –, *, =, ≤, ≥)

Inference

Constraint

propagation

LP relaxation

Local

Feasible

Global

Optimal

CP versus IP

• “MILP is very efficient when the relaxation is tight and

models have a structure that can be effectively exploited”

• “CP works better for highly constrained discrete

optimization problems where expressiveness of MILP is a

major limitation”

• “From the work that has been performed, it is not clear

whether a general integration strategy will always perform

better than either CP or an MILP approach by itself. This

is especially true for the cases where one of these

methods is a very good tool to solve the problem at hand.

However, it is usually possible to enhance the

performance of one approach by borrowing some ideas

from the other”

–

Source: Jain and Grossmann, 2001

Outline

•

•

•

•

•

Background

Introduction

Dantzig Wolfe decomposition

Benders decomposition

Conclusions

What is your background?

• Have implemented Benders and/or Dantzig Wolfe

decomposition

• Have heard about Benders and/or Dantzig Wolfe

decomposition

• Have seen Bender and/or Dances with Wolves

Things to take away

• A better understanding of how to combine linear

programming based decomposition techniques with

constraint programming

• A better understanding of column generation, Dantzig

Wolfe decomposition and Benders decomposition

• A whole lot of Python code with example implementations

Helpful installations

• Python 2.6.x or 2.7.x

– “Python is a programming language that lets you work more

quickly and integrate your systems more effectively”

– http://www.python.org/getit/

• Gurobi (Python interface)

– “The state-of-the-art solver for linear programming (LP), quadratic

and quadratically constrained programming (QP and QCP), and

mixed-integer programming (MILP, MIQP, and MIQCP)”

– http://www.gurobi.com/products/gurobi-optimizer/try-for-yourself

• NetworkX

– “NetworkX is a Python language software package for the

creation, manipulation, and study of the structure, dynamics, and

functions of complex networks”

– http://networkx.lanl.gov/download.html

Abbreviations

•

•

•

•

•

•

•

•

•

Artificial Intelligence (AI)

Constraint Programming (CP)

Constraint Satisfaction Problem (CSP)

Integer Programming (IP)

Linear Programming (LP)

Mixed Integer Programming (MIP)

Mixed Integer Linear Programming (MILP)

Mathematical Programming (MP)

Operations Research (OR)

Outline

•

•

•

•

•

Background

Introduction

Dantzig Wolfe decomposition

Benders decomposition

Conclusions

What is decomposition?

• “Decomposition in computer science, also known

as factoring, refers to the process by which a complex

problem or system is broken down into parts that are

easier to conceive, understand, program, and maintain”

–

Source: http://en.wikipedia.org/wiki/Decomposition_(computer_science)

• Decomposition in linear programming is a technique for

solving linear programming problems where the

constraints (or variables) of the problem can be divided

into two groups, one group of “easy” constraints and

another of “hard” constraints

“easy” versus “hard” constraints

• Referring to the constraints as “easy” and “hard” may be

a bit misleading

– The “hard” constraints need not be very difficult in themselves, but

they can complicate the linear program making the overall

problem more difficult to solve

– When the “hard” constraints are removed from the problem, then

more efficient techniques could be applied to solve the resulting

linear program

Example

G = (N, A), source s, sink t

• Shortest path problem (P)

Min (i,j)A cijxij

s.t.

1 for i = s

Source

j:(i,j)A xij – j:(j,i)A xji = 0 for iN – {s, t} Flow

-1 for i = t

Sink

xij {0, 1}

• Resource constrained shortest path problem (NP-complete)

Min (i,j)A cijxij

s.t.

1 for i = s

Source

j:(i,j)A xij – j:(j,i)A xji = 0 for iN – {s, t} Flow

-1 for i = t

Sink

(i,j)A dijxij ≤ C

Capacity

xij {0, 1}

Example

• Assignment problem (P)

Max i=1,…, m, j=1,…,n cijxij

s.t. j=1,…,n xij = 1

for 1 ≤ i ≤ m

i=1,…,m xij = 1

for 1 ≤ j ≤ n

xij {0, 1}

m jobs, n machines

Job

Machine

• Generalized assignment problem (NP-complete)

Max i=1,…, m, j=1,…,n cijxij

s.t. j=1,…,n xij = 1

for 1 ≤ i ≤ m

Job

i=1,…,m dijxij ≤ Cj

for 1 ≤ j ≤ n

Capacity

xij {0, 1}

Example

• Consider developing a strategic corporate plan for several

production facilities. Each facility has its own capacity and

production constraints, but decisions are linked together

at the corporate level by budgetary considerations

Common constraints

Facility 1

Independent

constraints

Facility 2

Facility n

“easy” versus “hard” variables

• Referring to the variables as “easy” and “hard” may be a

bit misleading

– The “hard” variables need not be very difficult in themselves, but

they can complicate the linear program making the overall

problem more difficult to solve

– When the “hard” variables are removed from the problem, then

more efficient techniques could be applied to solve the resulting

linear program

Example

• Capacitated facility location problem (NP-complete)

Min i=1,…,n,j=1,…,m cijxij + j=1,…,m fjyj

s.t. i=1,…,m xij ≥ 1

for j = 1,…, n

Demand

j=1,…,n dixij ≤ Ciyi

for i = 1,…, m

Roll

xij ≤ yi

for i = 1,…, m j = 1,…, n

Flow impl.

xij ≥ 0

m facilities, n customers

yi {0, 1}

Example

Common variables

• Consider solving a multi period scheduling problem. Each

period has its own set of variables but is linked together

through resource consumption variables

Period 1

Period 2

Period n

Independent variables

Outline

•

•

•

•

•

Background

Introduction

Dantzig Wolfe decomposition

Benders decomposition

Conclusions

Background

• Primal

Min cx

s.t. Ax ≥ b

x≥0

[y]

• Dual

Max yTb

s.t. yTA ≤ c

y≥0

[x]

Background

• Primal

Min cx

s.t. Ax ≥ b

x≥0

• Dual

Max bTy

s.t. ATy ≤ cT

y≥0

[y]

x

c

cx

A

Ax

[x]

y

b

bT

bTy

AT

ATy

cT

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Cost 60.78

Travelling salesman

• Variables

xij is 1 if arc (i, j) is on the shortest tour, 0 otherwise

• Formulation

Min (i,j)A cijxij

s.t. i:(i,j)A xij = 1

for j N

j:(i,j)A xij = 1

for i N

i,jS:(i,j)A xij ≤ |S| – 1 for S N

xij {0, 1}

Inflow

Outflow

Subtour

Travelling salesman

• Variables

xij is 1 if arc (i, j) is on the shortest tour, 0 otherwise

• Formulation

Min (i,j)A cijxij

s.t. i:(i,j)A xij = 1

j:(i,j)A xij = 1

xij {0, 1}

for j N

for i N

Inflow

Outflow

Example code

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Subtour

0, 2, 7

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Subtour

0, 8, 1, 9

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Subtour

0, 8, 2, 7

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Cost 79.98

Travelling salesman

• G = (N, A), cost cij

x

y

0

20

19

1

1

1

2

17

15

3

14

6

4

12

12

5

12

3

6

9

8

7

15

20

8

19

11

9

7

5

7

0

2

4

6

3

9

1

8

5

Cost 60.78

LPs with many constraints

• The number of constraints that are tight (or active) is at

most equal to the number of variables, so even with many

constraints (possibly exponential many) only a small

subset will be tight in the optimal solution

A

Active

Non-active

Row generation in the primal…

x

c

cx

A

Ax

b

… is column generation in the dual

y

bT

bTy

AT

ATy

cT

…and vice versa

x

y

c

cx

A

Ax

bT

bTy

AT

ATy

cT

b

Column generation

in the primal

=

Row generation

in the dual

Resource constrained shortest path

• G = (N, A), source s, sink t, for each (i, j) A, cost cij,

resource demand dij, and resource capacity C

Capacity = 14

2

1,10

1

1,1

4

2,3

1,7

1,2

10,1

10,3

5,7

3

i

12,3

cij, dij

6

2,2

5

j

Source: Desrosiers and Lübbecke, 2005

Resource constrained shortest path

• G = (N, A), source s, sink t, for each (i, j) A, cost cij,

resource demand dij, and resource capacity C

Capacity = 14

2

1,10

1

1,1

4

2,3

1,7

1,2

10,1

10,3

5,7

3

i

12,3

cij, dij

6

2,2

5

j

Cost 13

Demand 13

Resource constrained shortest path

• Variables

xij is 1 if arc (i, j) is on the shortest path, 0 otherwise

• Formulation

Min (i,j)A cijxij

s.t.

j:(i,j)A xij – j:(j,i)A xji =

(i,j)A dijxij ≤ C

xij {0, 1}

1 for i = s

Source

0 for iN – {s, t} Flow

-1 for i = t

Sink

Capacity

Example code

Resource constrained shortest path

• Variables

k is 1 if path k is the shortest path, 0 otherwise

• Formulation

Min kK ckk

s.t. kK k = 1

kK dkk ≤ C

k ≥ 0

Convex

Capacity

Arc versus path

• Arc variables

2

• Path variables

4

1

2

6

4

6

1

3

5

3

5

2

4

2

4

1

6

3

5

1

6

3

5

Example code

Revised Simplex method

• Min cx

s.t. Ax ≥ b

x≥0

Add slack variables

• Min z = cx

s.t. Ax = b

x≥0

• Let x be a basic feasible solution, such that x = (xB, xN)

where xB is the vector of basic variables and xN is the

vector of non-basic variables

Revised Simplex method

• Min z = cx

s.t. Ax = b

x≥0

• Min z = cBxB + cNxN

s.t. BxB + ANxN = b

xB, xN ≥ 0

x = (xB, xN), c = (cB, cN),

A = (B, AN)

Rearrange

• Min z = cBxB + cNxN

s.t. xB = B-1b – B-1ANxN

xB, xN ≥ 0

Revised Simplex method

• Min z = cBxB + cNxN

s.t. xB = B-1b – B-1ANxN

xB, xN ≥ 0

Substitute

• Min z = cBB-1b + (cN – cBB-1AN)xN

s.t. xB = B-1b – B-1ANxN

xB, xN ≥ 0

Revised Simplex method

• Min z = cBB-1b + (cN – cBB-1AN)xN

s.t. xB = B-1b – B-1ANxN

xB, xN ≥ 0

• At the end of each iteration we have

–

–

–

–

–

Current value of non-basic variables xN = 0

Current objective function value z = cBB-1b

Current value of basic variables xB = B-1b

Objective coefficients of basic variables 0

Objective coefficients of non-basic variables (cN – cBB-1AN) are the

so-called reduced costs

– With a minimization objective we want non-basic variables with

negative reduced costs

Revised Simplex method

• Simplex algorithm

1. Select new basic variable (xN to enter the basis)

2. Select new non-basic variable (xB to exit the basis)

3. Update data structures

Revised Simplex method

• Simplex algorithm

xS = b (slack variables equal rhs)

x\S = 0 (non-slack variables equal 0)

while minj{(cj – cBB-1Aj)} < 0

1. Select new basic variable j : (cj – cBB-1Aj) < 0

2. Select new non-basic variable j’ by increasing xj as much as

possible

3. Update data structures by swapping columns between matrix B

and matrix AN

Example

• Min z = – x1 – 2x2

s.t. – 2x1 + x2 ≥ 2

– x1 + 2x2 ≥ 7

x1 ≥ 7

x1 , x2 ≥ 0

• Min z = – x1 – 2x2

s.t. – 2x1 + x2 + x3 = 2

– x1 + 2x2 + x4 = 7

x1 + x5 = 7

x1 , x2 , x3 , x4 , x 5 ≥ 0

Add slack variables

Example

• Simplex method

bsc

x1

x2

x3

• Revised Simplex method

x4

x5

rhs

x2

bsc

x3

x4

x5

rhs

-z

-1

-2

0

0

0

0

-2

-z

0

0

0

0

x3

-2

1

1

0

0

2

1

x3

1

0

0

2

x4

-1

2

0

1

0

7

2

x4

0

1

0

7

x5

1

0

0

0

1

3

0

x5

0

0

1

3

bsc

x1

x2

x3

x4

x5

rhs

x1

bsc

x3

x4

x5

rhs

-z

-5

0

2

0

0

4

-5

-z

2

0

0

4

x2

-2

1

1

0

0

2

-2

x3

1

0

0

2

x4

3

0

-2

1

0

3

3

x4

-2

1

0

3

x5

1

0

0

0

1

3

1

x5

0

0

1

3

Example

• Simplex method

bsc

x1

x2

x3

• Revised Simplex method

x4

x5

rhs

x3

-z

0

0 -3/4

5/3

0

9

-3/4

x2

0

1 -1/3

2/3

0

4

x1

1

0 -2/3

1/3

0

x5

0

0

2/3 -1/3

1

bsc

x1

x2

x3

x4

x5

bsc

-z

x3

x4

x5

rhs

2

0

0

9

-1/3

x2 -1/3

2/3

0

4

1

-2/3

x1 -2/3

1/3

0

1

2

2/3

x5

2/3 -1/3

1

2

rhs

bsc

x3

x4

x5

rhs

-z

0

0

0

1

2

13

-z

0

0

0

13

x2

0

1

0

1/2

1/2

5

x2

0

1/2

1/2

5

x1

1

0

0

0

1

3

x1

0

0

1

3

x3

0

0

1 -1/2

3/2

3

x3

1 -1/2

3/2

3

Column generation

• Simplex algorithm

xS = b (slack variables equal rhs)

x\S = 0 (non-slack variables equal 0)

while minj{(cj – cBB-1Aj)} < 0

1. Select new basic variable j : (cj – cBB-1Aj) < 0

2. Select new non-basic variable j’ by increasing xj as much as

possible

3. Update data structures by swapping columns between matrix B

and matrix AN

In column generation, rather than checking the

reduced cost for each variable, a subproblem is

solved to find a variable with negative reduced cost

LPs with many variables

• The number of basic (non-zero) variables is at most equal

to the number of constraints, so even with many variables

(possibly exponential many) only a small subset will be in

the optimal solution

A

xB

xN

Column generation

• (cN – cBB-1AN) < 0

Substitute

• (cN – yTAN) < 0

Column generation

• (cN – yTAN) < 0

• Primal

Min cx

s.t. Ax ≥ b

x≥0

• Dual

Max yTb

s.t. yTA ≤ c

y≥0

x

Column with negative

reduced cost

c

cx

A

Ax

Row with

violated rhs

b

y

bT

bTy

AT

ATy

cT

Resource constrained shortest path

• Variables

k is 1 if path k is the shortest path, 0 otherwise

• Formulation

Min kK ckk

s.t. kK k = 1

kK dkk ≤ C

k {0, 1}

Convex

Capacity

Resource constrained shortest path

• Primal

Min kK ckk

s.t. kK k = 1

kK dkk ≤ C

k ≥ 0

[]

[]

• Dual

Max + C

s.t. + dk ≤ ck

= free

≤0

Need to find a path for which

ck – – dk < 0

Implicitly search all paths by optimizing

Min (i,j)A (cij – dij)

s.t. Source, Flow, Sink

[k]

Resource constrained shortest path

• G = (N, A), source s, sink t, for each (i, j) A, cost cij,

resource demand dij, and resource capacity C

Capacity = 14

1

2

1

1

4

2

1

1

6

10

10

5

3

i

2

12

(cij – dij)

5

j

Resource constrained shortest path

• Master

Min kK ckk

s.t. kK k = 1

kK dkk ≤ C

k ≥ 0

• Subproblem

Min (i,j)A (cij – dij)xij

s.t.

j:(i,j)A xij – j:(j,i)A xji =

Convex

Capacity

1 for i = s

Source

0 for iN – {s, t} Flow

-1 for i = t

Sink

• Add variable to master if (i,j)A (cij – dij)xij – < 0

Example code

Cutting stock

• Roll width W, m orders of di rolls of length li, i = 1,…, m

100

11 x

4x

4x

2x

di

12

31

36

45

li

Cutting stock

• Roll width W, m orders of di rolls of length li, i = 1,…, m

12

12

31

12

12

12

12

36

12

12

36

36

36

12

31

12

12

31

31

45

45

11 x

4x

4x

2x

di

12

31

36

45

li

96

96

98

100

100

Rolls 5

Cutting stock

• Variables

xik is the number of times order i is cut from roll k

yk is 1 if roll k is used, 0 otherwise

• Formulation

Min k=1,…,K yk

s.t. k=1,…,K xik ≥ di

i=1,…,n lixik ≤ Wyk

xik ≥ 0 and integer

yk {0, 1}

for i = 1,…, n

for k = 1,…, K

Demand

Roll

Example code

Cutting stock

• Variables

k is the number of times cutting pattern k is used

• Formulation

Min kK k

s.t. kK aikk ≥ di for i = 1,…, m

k ≥ 0 and integer

Demand

Cutting stock

• Cutting pattern variables

k 12

12

36

36

aik [2, 0, 2, 0]

k 12

aik

12

[2, 1, 0, 1]

31

11 x

4x

4x

2x

45

12

31

36

45

Cutting stock

• Primal

Min kK k

s.t. kK aikk ≥ di

k ≥ 0

[i]

• Dual

Max i=1,…,n dii

s.t. i=1,…,n aiki ≤ 1

i ≥ 0

Need to find a cutting pattern for which

1 – i=1,…,n aiki < 0

Implicitly search all cutting patterns by optimizing

Max i=1,…,n aii

s.t. i=1,…,n liai ≤ W

ai ≥ 0 and integer

[k]

Cutting stock

• m items with value i and weight li, i = 1,…, m, maximum

allowed weight W

100lbs

12

12

36

36

$0.125, 12lbs

0.125 12

$0.33, 31lbs

0.33 31

$0.50, 36lbs

0.50 36

$0.50, 45lbs

0.50 45

i

li

Cutting stock

• Master

Min kK k

s.t. kK aikk ≥ di for i = 1,…, m

k ≥ 0

• Subproblem

Max i=1,…,m aii

s.t. i=1,…,m liai ≤ W

ai ≥ 0 and integer

• Add variable to master if 1 – aii < 0

Demand

Example code

Generalized assignment

• n jobs, m machines, cost cij, demand dij, capacity Ci

Job

1

1

2

1

17, 8 23, 15

2

21, 15

16, 7

3

22, 14 21, 23

4

18, 23 16, 22

5

24, 8 17, 11

2

1

36

2

34

i

Cj

3

4

5

j

cij, dij

Generalized assignment

• n jobs, m machines, cost cij, demand dij, capacity Ci

Job

1

1

2

1

17, 8 23, 15

2

21, 15

16, 7

3

22, 14 21, 23

4

18, 23 16, 22

5

24, 8 17, 11

2

1

36

30

2

34

29

3

4

Cost 95

5

j

cij, dij

i

Cj

Generalized assignment

• Variables

xij is 1 if job j is assigned to machine i, 0 otherwise

• Formulation

Max i=1,…,m,j=1,…,n cijxij

s.t. i=1,…,m xij = 1

j=1,…,n dijxij ≤ Ci

xij {0, 1}

for 1 ≤ j ≤ n Job

for 1 ≤ i ≤ m Capacity

Example code

Generalized assignment

• Variables

ik is 1 if machine i has job assignment k, 0 otherwise

• Formulation

Max i=1,…,m,k=1,…,Ki cikik

s.t. i=1,…,m,k=1,…,Ki aijkik = 1

k=1,…,Ki ik = 1

ik {0, 1}

for 1 ≤ j ≤ n Job

for 1 ≤ i ≤ m Convexity

Generalized assignment

• Job assignment variables

1

2

ik

1

1

ik

3

4

5

aijk [1, 0, 1, 0, 1]

2

2

1

3

4

5

aijk [0, 1, 0, 1, 0]

2

Generalized assignment

• Formulation

Max i=1,…,m,k=1,…,Ki cikik

s.t. i=1,…,m,k=1,…,Ki aijkik = 1

k=1,…,Ki ik = 1

ik {0, 1}

for 1 ≤ j ≤ n Job

for 1 ≤ i ≤ m Convexity

Common constraints

Machine 1

Independent

constraints

Machine 2

Machine n

Generalized assignment

• Primal

Max i=1,…,m,k=1,…,Ki cikik

s.t. i=1,…,m,k=1,…,Ki aijkik = 1

k=1,…,Ki ik = 1

ik ≥ 0

• Dual

Min j=1,…,n j + i=1,…,m i

s.t. j=1,…,n aijkj + i ≥ cik

j = free

i = free

Need to find a cutting pattern for which

j=1,…,n (cik – aijkj ) – i > 0 for i = 1,…,m

Implicitly search all cutting patterns by optimizing

Max j=1,…,n (cij – aijj )

s.t. j=1,…,n dijaij ≤ Ci

aij ≥ 0 and integer

Generalized assignment

• n items with value j and weight dij, j = 1,…, n, maximum

allowed weight W

Job

36lbs

$44.00, 8lbs

1

1

1

44, 8

2

55, 15

3

51, 14

4

52, 23

5

55, 8

Job

40, 15

2

37, 7

$51.00, 14lbs

3

43, 23

$52.00, 23lbs

4

34, 22

5

41, 11

$55.00, 8lbs

1

36

3

4

2

5

1

2

1

$55.00, 15lbs

2

2

1

3

4

5

2

34

Generalized assignment

• Master

Max i=1,…,m,k=1,…,Ki cikik

s.t. i=1,…,m,k=1,…,Ki aijkik = 1

k=1,…,Ki ik = 1

ik {0, 1}

for 1 ≤ j ≤ n Job

for 1 ≤ i ≤ m Convexity

• Subproblem (for each machine i)

Max j=1,…,n (cij – aijj )

s.t. j=1,…,n dijaij ≤ Ci

aij ≥ 0 and integer

• Add variable to master if j=1,…,n (cij – aijj ) – i > 0

Example code

History of column generation

1958: A suggested computation for maximal multicommodity network flows

L.R. Ford and D.R. Fulkerson

1960: Decomposition principle for linear programs

G.B. Dantzig and P. Wolfe

“Credit is due to Ford and Fulkerson for their proposal for solving multicommodity

network problems as it served to inspire the present development.”

1961: A linear programming approach to the cutting-stock problem

P.C. Gilmore and R.E. Gomory

1963: A linear programming approach to the cutting-stock problem–Part II

P.C. Gilmore and R.E. Gomory

1969: A column generation algorithm for a ship scheduling problem

L.E. Appelgren

Solving integer programs by column generation

1984: Routing with time windows by column generation

Y. Dumas, F. Soumis and M. Desrochers

1998: Branch-and-price: column generation for solving huge integer programs

C. Barnhart, E.L. Johnson, G.L. Nemhauser, M.W.P. Savelsbergh and P.H. Vance

2000: On Dantzig-Wolfe decomposition in integer programming and ways to

perform branching in a branch-and-price algorithm

F. Vanderbeck

2005: A primer in column generation

J. Desrosiers and M.E. Lubbecke

2011: Branching in branch-and-price: a generic scheme

F. Vanderbeck

CP-based column generation

1999: A framework for constraint programming based column generation

U. Junker, S.E. Karisch, N. Kohl, B. Vaaben, T. Fahle and M. Sellmann

2000: Solving very large crew scheduling problems to optimality

T.H. Yunes, A.V. Moura and C.C. de Souza

CP-based column generation

Application

Reference

CP used to solve

subproblem

CP used within

Branch-and-Price

Urban transit crew

management

T.H. Yunes., A.V. Moura, C.C.

de Souza. 2000.

Y

Y

T.H. Yunes., A.V. Moura, C.C.

de Souza. 2005.

Y

Y

Travelling

tournament

K. Easton, G.L. Nemhauser, and

M.A. Trick. 2002.

Y

Y

Two-dimensional

bin packing

D. Pisinger, M. Sigurd. 2007.

Y

Y

Graph coloring

S. Gualandi. 2008.

Y

Y

Constrained cutting

stock

T. Fahle, M. Sellmann. 2002.

Y

N

Employee

timetabling

S. Demassey, G. Pesant, L.M.

Rousseau. 2006.

Y

Y

Wireless mesh

networks

A. Capone, G. Carello, I.

Filippini, S. Gualandi, F.

Malucelli. 2010.

Y

N

Multi-machine

scheduling

R. Sadykov, L.A. Wolsey. 2006.

Y

N

Source: Gualandi and Malucelli, 2009

CP-based column generation

Application

Reference

CP used to solve

subproblem

CP used within

Branch-and-Price

Airline crew

assignment

U. Junker, S.E. Karisch, N.

Kohl, B. Vaaben, T. Fahle, M.

Sellmann. 1999.

Y

N

T. Fahle, U. Junker, S.E.

Karisch, N. Kohl, M. Sellmann,

B. Vaaben. 2002.

Y

N

M. Sellmann, K. Zervoudakis, P.

Stamatopoulos, T. Fahle. 2002.

Y

N

L.M. Rousseau. 2004.

Y

N

L.M. Rousseau, M. Gendreau,

G. Pesant, F. Focacci. 2004.

Y

Y

Vehicle routing with

time windows

Source: Gualandi and Malucelli, 2009

CP-based column generation

• Typical implementation

Dual

information

Master

Linear

programming

Subproblem

New

columns

Constraint

programming

Outline

•

•

•

•

•

Background

Introduction

Dantzig Wolfe decomposition

Benders decomposition

Conclusions

Two-stage optimization

Stage 1

Solution

values

Stage 2

Benders decomposition

Solution

values

Stage 1

Stage 2

Benders

cuts

Benders decomposition

“Learn from ones mistakes”

Distinguish primary variables from secondary variables

Search over primary variables (master problem)

For each trial value of primary variables, solve problem over

secondary variables (subproblem)

If solution is suboptimal/infeasible, find out why and design a

constraint that rules out not only this solution but a large class of

solutions that are suboptimal/infeasible for the same reason

(Benders cut)

Add Benders cut to the master problem and resolve

Solution

values

Master

Subproblem

Benders

cuts

Capacitated facility location

• m facilities, n customers, cost cij, demand dj, capacity Ci,

fixed cost fi

Cust 1

2

3

1

2

4

5

2

3

3

4

3

4

1

2

4

5

2

1

5

7

6

3

10, 3

10, 4

10, 4

Ci, fi

1

6

2

4

3

8

4

7

5

5

j

dj

1

2

3

i

cij

Capacitated facility location

• m facilities, n customers, cost cij, demand dj, capacity Ci,

fixed cost fi

Cust 1

2

3

1

2

4

5

2

3

3

4

3

4

1

2

4

5

2

1

5

7

6

3

10, 3

10, 4

10, 4

6

2

4

3

8

4

7

5

5

j

dj

1

2

3

Cost 21.29

Ci, fi

1

i

cij

Capacitated facility location

• Variables

xij fraction of demand supplied by facility i to cusomter j

yi is 1 if facility i is open, 0 otherwise

• Formulation

Min i=1,…,n,j=1,…,m cijxij + j=1,…,m fjyj

s.t. i=1,…,m xij ≥ 1

for j = 1,…, n

j=1,…,n dixij ≤ Ciyi

for i = 1,…, m

xij ≤ yi

for i = 1,…, m j = 1,…, n

xij ≥ 0

yi {0, 1}

Demand

Roll

Flow

Example code

Benders decomposition

• Min cx + dy

s.t. Ax ≥ b

Px + Qy ≥ r

x ≥ 0 and integer

y≥0

Master

• Min cx +

s.t. Ax ≥ b

x ≥ 0 and integer

≥0

•

Solution

values

Benders

cuts

Subproblem

Min dy

s.t. Qy ≥ r – Px

y≥0

What if the subproblem

is infeasible?

Benders decomposition

• Primal, dual possibilities

Dual

Primal

Optimal

Unbounded

Infeasible

Optimal

Yes

No

No

Unbounded

No

No

Yes

Infeasible

No

Yes

Yes

Benders decomposition

• Min cx + dy

s.t. Ax ≥ b

Px + Qy ≥ r

x ≥ 0 and integer

y≥0

Master

• Min cx +

s.t. Ax ≥ b

optimality cuts

feasibility cuts

x ≥ 0 and integer

≥0

•

Solution

values

Benders

cuts

Subproblem

Min dy

s.t. Qy ≥ r – Px

y≥0

Benders decomposition

• Min dy

s.t. Qy ≥ r – Px

y≥0

[u]

• Max uT(r – Px)

s.t. uTQ ≤ d

u≥0

• Optimal

• Optimality cut

≥ ukT(r – Px)

• Infeasible

• Infeasibility cut

vkT(r – Px) ≤ 0

[y]

Benders decomposition

• Min cx + dy

s.t. Ax ≥ b

Px + Qy ≥ r

x ≥ 0 and integer

y≥0

Master

• Min cx +

s.t. Ax ≥ b

≥ ukT(r – Px)

vkT(r – Px) ≤ 0

x ≥ 0 and integer

≥0

•

Solution

values

Benders

cuts

Subproblem

Max dy

s.t. Qy ≤ r – Px

y≥0

Benders decomposition

START

Solve master

problem

yes

Terminate?

no

Solve sub

problem

Add

optimality cut

yes

Is optimal?

END

Add

feasibility cut

no

Capacitated facility location

• Variables

xij fraction of demand supplied by facility i to cusomter j

yi is 1 if facility i is open, 0 otherwise

• Formulation

Min i=1,…,n,j=1,…,m cijxij + j=1,…,m fjyj

s.t. i=1,…,m xij ≥ 1

for j = 1,…, n

j=1,…,n dixij ≤ Ciyi

for i = 1,…, m

xij ≤ yi

for i = 1,…, m j = 1,…, n

xij ≥ 0

yi {0, 1}

Demand

Roll

Flow

Capacitated facility location

• Master

Min j=1,…,m fjyj +

s.t. optimality cuts

feasibility cuts

yi {0, 1}

≥0

• Subproblem

Min i=1,…,n,j=1,…,m cijxij

s.t. i=1,…,m xij ≥ 1

for j = 1,…, n

j=1,…,n dixij ≤ Ciyi

for i = 1,…, m

xij ≤ yi

for i = 1,…, m j = 1,…, n

xij ≥ 0

Demand

Roll

Flow

Capacitated facility location

• Subproblem primal

Min i=1,…,n,j=1,…,m cijxij

s.t. i=1,…,m xij ≥ 1

j=1,…,n dixij ≤ Ciyi

xij ≤ yi

xij ≥ 0

[j]

[i]

[ij]

• Subproblem dual

Max j=1,…,m j + i=1,…,n Ciyii + i=1,…,n,j=1,…,m yiij

s.t. j + dii + ij ≥ 1

[xij]

j ≥ 0

i ≤ 0

ij ≤ 0

Capacitated facility location

• Master

Min j=1,…,m fjyj +

s.t. ≥ j=1,…,m j + i=1,…,n Ciiyi + i=1,…,n,j=1,…,m ij yi

j=1,…,m j + i=1,…,n Ciiyi + i=1,…,n,j=1,…,m ij yi ≤ 0

yi {0, 1}

≥0

Example code

Benders decomposition for stochastic prog.

Scenario 1

Master

Scenario 2

Scenario 3

Capacitated facility location

• m facilities, n customers, cost cij, demand dj, capacity Ci,

fixed cost fi

Cust 1

2

3

1

2

4

5

2

3

3

4

3

4

1

2

4

5

2

1

5

7

6

3

10, 3

10, 4

10, 4

Ci, fi

1

6

5

4

2

4

3

2

3

8

7

6

4

7

6

5

5

5

4

3

j

dj

1

2

3

i

cij

Example code

CP-based Benders decomposition

• Typical implementation(?)

Solution

values

Master

Constraint

programming

Subproblem

Benders

cuts

Linear

programming

CP-based Benders decomposition

• Recent developments

Solution

values

Master

Integer

programming

Subproblem

Benders

cuts

Constraint

programming

CP-based Benders decomposition

Application

Reference

Master problem

Subproblem

Parallel machine

scheduling

V. Jain, I.E. Grossmann. 2001.

MILP

CP

Polypropylene batch

scheduling

C. Timpe. 2002.

MILP

CP

Call center scheduling

T. Benoist, E. Gaudin, B. Rottembourg.

2002.

CP

LP

Multi-machine

scheduling

J.N. Hooker. 2004.

MILP

CP

J.N. Hooker. 2005.

MILP

CP

Source: Hooker, 2006

Nested Benders decomposition

• Nested Benders decomposition

– When the subproblem is decomposed into a master and

subproblem

Master

Master

Forward pass

Solve master

problems

Sub

Backward pass

Solve subproblems

and add Benders cuts

Sub

Master

Master

Sub

Sub

Outline

•

•

•

•

•

Introduction

Background

Dantzig Wolfe decomposition

Benders decomposition

Conclusions

Why use decomposition?

• Many real-world systems contain loosely connected

components, and as a result, the corresponding

mathematical models present a certain structure that can

be exploited

• It may be your only choice when solving the model

without decomposition is impossible, because it is too

large (memory error or timeout)

When is decomposition likely most effective?

• When you have either complicating constraints or

complicating variables

Dantzig Wolfe

decomposition

Benders

decomposition

Further reading

• Column Generation

– Guy Desaulniers, Jacques Desrosiers, Marius M. Solomon

• Decomposition Techniques in Mathematical Programming

– Antonio J. Conejo, Enrique Castillo, Roberto Minguez and Raquel

Garcia-Bertrand

• Linear Programming and Network Flows

– Mokhtar S. Bazaraa, John J. Jarvis, Hanif D. Sherali

From imagination to impact