PPT - University of Dayton Academic Webserver

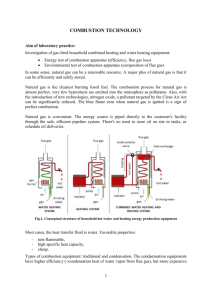

advertisement

Energy Efficient Process Heating Energy Balance on Furnace Energy Saving Opportunities From Energy Balance Reduce opening losses: radiation and air exchange Reduce cooling losses Reduce conveyance losses Reduce storage losses Reduce wall losses Reduce flue losses – Improve internal heat transfer – Reduce air leakage into furnace – Control combustion air / oxygen Reclaim heat – Pre-heat combustion air – Pre-heat load – Cascade heat to lower temperature processes Reduce Opening Losses Reduce Radiation Losses: ‘Room’ for Improvement Reduce Radiation Losses: ‘Better’ Cover Charge Wells 2 ft x 4 ft open charge well radiates and convects heat Cover charge well with mineral fiber insulation 75% of time Savings = $1,500 /yr Preheating Ladles: Too Much Space Preheating Ladles: Nice Tight Fit Reducing Air Exchange in Continuous Ovens By Modifying Entrance/Exit Reduce Cooling Losses Reduce Conveyance Losses Slow conveyor – – – – Brazing oven at 1,900 F Conveyor runs at 0.7 ft/min Conveyor loaded 30% of time Slow conveyor to 0.3 ft/min when unloaded – Reduces conveyor losses by 40% Reduce Conveyance Losses Lighter conveyance fixtures reduce energy carryout losses Reduce Storage Losses Larger batch sizes to reduce number of loads in heat treat ovens Reduce Storage Losses Reduce bricks (thermal mass) on transport cars Reduce Storage Losses Increase batch sizes in arc furnaces Reduce Wall / Surface Losses Insulate Hot Surfaces Insulate four lids at 400 F Induction furnace efficiency = 51% Savings = $17,0000 /yr Insulate Extruder Barrels Turn Off Heat When Not in Use Heat Loss at Contant Temperature 400 350 300 Temp (F) Heating Savings 250 Heating Energy 400 200 350 150 300 Temp (F) 100 50 0.1 1.1 2.1 3.1 4.1 5.1 6.1 7.1 8.1 9.1 250 Savings Heating Energy 200 150 Heat Loss With 8-hour Cooldown and 2-hour Reheat 100 400 50 350 1 Temp (F) 300 250 Heating Energy 200 150 100 50 0.1 1.1 2.1 3.1 4.1 5.1 6.1 7.1 8.1 9.1 11 21 31 41 51 61 71 81 91 Reduce Flue Losses Flue Losses Flue losses increase with: – Temperature – Flow Reduce Flue Losses Reduce Temperature – Improve internal heat transfer Reduce Flow – Reduce air leakage into furnace – Combustion air control – Use O2 instead of ambient air for combustion Counter Flow Heat Transfer Reduces Exhaust Temperature T Q Parallel Flow T x Q Counter Flow x Convert Batch Cross Flow Processes to Continuous Counter Flow Batch crucible melting Counter-flow cupola melting Replace Reverb (Cross Flow) with Stack (Counter Flow) Furnace and Pre-heat Charge Reverb Furnace Stack Furnace Lead Melt Furnace: Place Scrap on Top and Drain Molten Lead From Bottom Molten Glass Transport: Each Exhaust Port Is A Zone Relocate Exhaust Ports to Increase Counter-flow Within Zones Contact length = 2 x (5 + 4 + 3 + 2 + 1) = 30 feet Contact length = (10 + 9 + 8 + 7 + 6 + 5 + 4 + 3 + 2 + 1) = 55 feet Increases convection heat transfer by 83% Set Exhaust Dampers to Increase Counter Flow in Dry Off Oven Product In 100% open Product Out 75% open 50% open 25% open 12% open Set Exhaust Dampers to Increase Counter Flow in Tile Kiln Tile Exit Tile Entrance Reduce Flue Flow Reduce Air Leakage Heat in Flue Gases Combustion Air Fuel Negative Pressure Air Leaks Seal Furnace Openings Seal opening around lid with mineral fiber blanket Use Draft Control to Balance Pressure Flue damper Counterweight Hydraulic cylinder Hydraulic power unit Controller Compensating line Pressure tap (not in line with opposing burner) Reduce Flue Flow: Control Combustion Air Combustion with Air Minimum Combustion Air (Stoichiometric): CH4 + 2 (O2 + 3.8 N2) CO2 + 2 H2O + 7.6 N2 Excess Combustion Air: CH4 + 4 (O2 + 3.8 N2) CO2 + 2 H2O + 15.2 N2 + 2 O2 % Available Heat Excess Combustion Air Decreases Flame Temperature and Efficiency Flue gas temperature) Reduce Excess Air To 10% or CO Limit Reduce Flue Flow: Replace Air with Oxygen Combustion with Oxygen Eliminates Unnecessary Nitrogen Combustion with Air – CH4 + 2 (O2 + 3.8 N2) > CO2 + 2 H2O + 7.6 N2 – Mair / Mfuel = [ (4 x 16) + (4 x 3.8 x 14) ] / (12 + 4) – Mair / Mfuel = 17.6 Combustion with O2 – CH4 + 2 O2 > CO2 + 2 H2O – Mo2 / Mfuel = (4 x 16) / (12 + 4) – Mo2 / Mfuel = 4.0 Combustion with Oxygen Increases Flame Temperature Combustion with Oxygen Increases Efficiency Reclaim Heat Preheat combustion air Preheat load/charge Cascade to lower temperature process Preheat Combustion Air with External Recuperator Preheat Combustion Air with External Recuperator comb. air out Tc2 = 615 F ex. gas out Th2 = 950 F comb. air in Tc1 = 95 F ex. gas in Th1 = 1,465 F Preheat Combustion Air with External Recuperator Preheat Combustion Air with Bayonet Recuperator Preheat Combustion Air with Tube-in-Tube Heat Exchanger Preheat Combustion Air with Regenerators Pre-heat Load Using Counter-flow Stack Current Design Recommended Design Burners Preheat Load Using Counter-flow Preheat Load Using Preheating Shed Cascade Heat to Lower-Temperature Process High Temperature Oven Low Temperature Oven Cascade Heat to Waste Heat Boiler VOC Destruction with Thermal and Catalytic Oxidizers Reduce VOC Stream Pre-heat VOC Stream with Recuperator Pre-heat VOC Stream with Regenerator Use Thermal Oxider Exhaust Reduce VOC Stream with Carbon Adsorber Inlet: 50,000 cfm with 50 ppm Outlet: 5,000 cfm with 500 ppm (10x concentration) Outlet (BAC): 50 cfm with 50,000 ppm (1,000x concentration) Preheat VOC Stream in Thermal Oxidizer with Regenerator Preheat VOC Stream in Catalytic Oxidizer with Recuperator Plant Air Tc,1 = 72 F Exhaust Air Counter-Flow Heat Exchanger Burner QHXR Qc QNG Tc,2 Th,1 = 625 F Texhaust stream = 300 F Tc,3 = 560 F Catalytic Oxidizer Use Thermal Oxidizer Exhaust: Direct Contact Water Heater And Don’t Get Covered with Molten Metal !