U06_NA3-Construction - Port Fest Baltimore 2015

advertisement

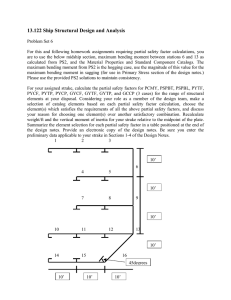

Ship Construction Framing Systems Double Bottom Construction Stem & Stern Construction Transverse Framing: Many, closelyspaced Frames Deck Beams tie upper ends of frames Fewer, deeper & more widely spaced Longitudinals … Support Inner Bottom & give longitudinal strength Longitudinals supporting Decks are called (Deck) Girders Additional Decks (supported by Beams & Girders) increase Transverse & Longitudinal strength Transverse Bulkheads provide watertight boundaries, contribute significantly to transverse strength, and provide vertical support for Decks Transverse Framing: Many, closelyspaced Frames Advantages Open, nearly rectangular interior space Ideal for stowing large, irregular, break-bulk items, or Vehicles (Ro-Ro’s) Disadvantages Vertical support for decks requires more closely spaced transverse bulkheads (hence smaller compartments) or Pillars (stanchions) or Longitudinal bulkheads Longitudinal Framing: Deep (Web) Transverse Frames Few & widely spaced Smaller, closelyspaced Longitudnals support shell plating Side shell longitudinals call stringers Inner Bottom gives additional longitudinal & transverse strength Girders in high-stress areas: Double bottom spaces and … Under main deck Longitudinal Framing: Deep (Web) Transverse Frames Advantages Widely spaced transverse bulkheads allow for large (i.e., long) continuous cargo spaces (“tanks”) Ideal for stowing liquids (reduced free surface effects) Disadvantages No large, open interior spaces Difficult to load or unload break-bulk items Difficult to stow large, irregular shaped items Framing Systems: Typically, most ships have some combination of transverse & longitudinal framing L TTTTT UPPER TWEEN DECK (LOWER) HOLD SECTION VIEW L L L L L L L L Bulkhead STIFFENERS TTTTTTTTTTTT LOWER TWEEN DECK L Stringer Web Frame Typical Transverse Frames FLOOR CL PLAN VIEW CL Double Bottom details: Inner Bottom (Tank Top) Rider Plate Airhole Margin Plate Frame Center Vertical Keel Keel Plate Outer Bottom Longitudinal Bilge “SOLID” FLOOR Lightening hole Reverse Frame Frame Longitudinal Limber hole Bilge well “OPEN” FLOOR Strut Shell Plating details: (Longitudinal) Rows of plating are called “strakes” The Keel Plates form the “Keel strake” The strakes outboard (P&S) of the Keel are the “A” Strakes or “Garboard Strakes” Strakes are consecutively lettered moving outboard and up the side shell “G” Strake “B” Strake Keel Strake Garboard Strake (“A” strake) “C” Strake “D” Strake “E” Strake “F” Strake (Bilge Strake) Shell Plating details: (Longitudinal) Rows of plating are called “strakes” Welded horizontal joints between strakes are called seams Welded vertical joints between plates in a given strake are called butts Strakes that do not run the entire ship length (as the hull surface area decreases at the ends) are drop strakes “K” Strake “J” Strake Sheer Strake Through “H” Strake drop “G” Strake Bilge (“F”) Strake Strakes running stem to stern are called through strakes An oversized plate merging a drop & through strake is a stealer plate The strake at the deck edge is the sheer strake and is heavier than typical side shell plating Openings in shell plating must: *have rounded corners *be reinforced to make up for missing material … and on weather deck -- COAMINGS portholes Hatch openings below decks Watertight doors Stem Construction Wrapper Plate Stem Decks Forward Collision Bulkhead Wrapper Plate Stem Stringers Vertical Stem Post Rider Plate Deep Floors C.V. Keel Keel Plate Breast Hooks Stern Construction After Collision Bulkhead Stern Frame Steering Gear Room Rudder Stock Deck Mach’y Rm Cant Frames Rope Locker After Peak Lug Stern Tube Tank Rudder Post Propeller Post Stern Frame UNBALANCED RUDDER Pintle Gudgeon SEMI-BALANCED RUDDER