LEC - wec civilians

advertisement

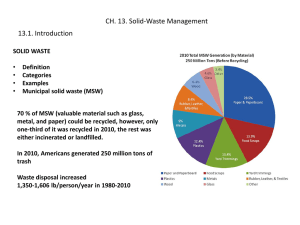

Solid Waste Engineering & Management Introduction • MSW generally refers to all wastes generated, collected, transported, and disposed of within the jurisdiction of a municipal authority. Sources of solid waste Strategies of Solid waste management Types of Solid Wastes • Paper Category • Plastic Category • Glass Category • Metal Category • Yard Waste Category • Organic Category • Other Waste Category • Special Waste Category i. Paper Category • Mixed Paper • Newspaper • Non Recyclable Paper ii. Plastic Category • Polyethylene tri-phthalate containers • High density polyethylene containers • Polyvinyl chloride containers • Low density polyethylene • Poly propylene • Polystyrene • Other plastics iii. Glass Category • Recyclable Glass • Non Recyclable Glass iv. Metal Category • Aluminum Cans • Ferrous Metals • Non Ferrous Metals • White Goods v. Yard Waste Category • Yard Waste vi. Organic Category • Organic Compactable • Organic Non Compactable • Tires & Rubber vii. Other Waste Category • Inert Slides (Inert Wastes) • Household Hazardous Wastes • viii. Special Waste Category • Sewerage Sludge • Other Special Wastes Physical Properties • Composition Of MSW • Moisture Content • Generation Of Solid Waste • Density Of Solid Waste • Particle Size Distribution • Field Capacity • Permeability Of Compacted Waste Composition of MSW • By composition we mean components of solid waste by % wt. • Varies with location, season, economic conditions • Food waste, largest component in low income countries, being not trimmed & absence of grinder. • Percentage of plastic waste and paper waste is increasing with the passage of time. Moisture Content • Expressed in two ways • Wet weight measurement (% wet weight of material) • Dry weight method (% dry weight of material) • Wet weight commonly used in SWM • Moisture content of samples analyzed in lab. • Where, • M = moisture content • W = initial wt of sample, (kg) • D = weight of sample drying at 105oC (kg) • For food & yard waste, various 15-40%, • Plastic & inorganic, 3% Generation of Solid Waste • Expressed in per capita. • 0.65 kg/c/day in 2002. (for Rawalpindi City) Density of SW • Specific wt, expressed in material per unit volume, lb/yd3 • Data needed to assess total mass & volume of solid waste • Vary with location, season & length of time in storage Particle Size Distribution • Important consideration in recovery (recycling & reuse) of material, especially with mechanical means such as magnetic separators. • Relevant to incineration & biological transformation methods. • Largest dimension is up for sizing facilities like conveyor belts & grinders etc. • Shredders & separators are used to reduce to desirable sizes for treatment of composting etc. Field Capacity • Total amount of moisture that can be retained in a waste sample subject to downward pull of gravity. • Water in excess of field capacity will be released as leachate • Field capacity varies with the degree of applied pressure & state of decomposition of the waste. • Field capacity of un-compacted wastes from residential & commercial sources, 50-60%. Permeability of Compacted Waste • Hydraulic conductivity governs the movement of liquids & gases in a infill. • Sludge in land fills tends to resist the movement of water down through then due to low hydraulic conductivity by virtue of very high moisture content. Instead, rainfall is converted to surface runoff & sludge material is transported to surface streams. • Paper & packaging has no resistance to rain in filtration • Hydraulic conductivity of soil governs the transport rate of leachate within the solid waste fill. Chemical Composition of MSW • Chemical composition is important in evaluating alternative processing & recovery options. • If solid wastes to be used as fuel, four most important properties to be known are: • Proximate analysis • Fusing point of ash • Ultimate analysis (major elements) • Energy content • Where organic fraction of MSW to be composted or to be used a feedstock for the production of other biological conversion products, not only will information on the major elements (ultimate analysis) that compose the waste be important, but also information will be required on the trace elements in the waste. Proximate Analysis • Proximate analysis for combustible components of MSW included following tests: • Moisture content by % wt (loss of moisture when heated to 1050c for 1 hr) • Volatile combustible matter (loss of wt on ignition at 9500c in a covered crucible) • Fixed carbon (combustible residue left after volatile matter is removed) • Ash (wt of residue after combustion in an open crucible) Fusion Point Ash • Temperature at which ash resulting from the burning of waste will form a solid (clinker) by fusion & agglomeration. • Typical fusion temp ranges from 2000-2200oF (1100-1200o C) Ultimate Analysis of SW Components • Determination of percent of C, H, O, N, S & Ash • Used to characterize the chemical composition of the organic matter in MSW • Use to define proper mix of waste materials to achieve suitable C/N ratios for biological conversion processes Energy Contents of SW Components • Can be determined by using a full scale boiler as a calorimeter • By using a lab bomb colorimeter. • By calculation, if elemental compose is known • Potentially critical element in incineration can be measured or calculated using • DuLong Formula: • Btu/lb = 145C +610(H -1/8 O) + 40S +10N • Btu per lb on a dry ash-free basis is btu/lb (dry ash-free) = btu/lb (as discarded) • Approximate btu values for waste material can be determined by using modified dulong formula. • Btu/lb = 145c+610 (h2-1/8 o2)+40s+10n • Constituents are % by weight. Biological Composition of MSW • Excluding plastic, rubber & leather components organic fraction of most MSW can be categorized as follows: • Water soluble constituents-as sugars, starches, amino acid & various organic acids • Hemi cellulose-a condensation product of 5 or 6-carbon sugars. • Cellulose a condensation product of 6-carbon sugar glucose • Fats, oils & waxes, which are esters of alcohols & long-chain fatty acids. • Lignin a polymeric material containing aromatic rings with methoxyle groups (-OCH3), the exact chemical nature of which is still not known • Lignocelluloses-a combination of lignin & cellulose. • Proteins-composed of chains of amino acids. • Almost all organic fraction of MSW can be converted biologically to gases & relatively inert organic & inorganic solids. Bio Degradability of Organic Waste • Biodegradation can be aerobic or anaerobic. • Volatile slides contents, determined by ignition at 5500C, are often used as a measure of degradability of organic fraction of MSW. • Use of VS in describing the biodegradability of organic fraction is misleading as some constituents are highly volatile but low in biodegradability. • Alternatively, lignin content of a waste can be used to estimate the biodegradable fraction, as: • • • • BF = 0.83 – 0.028 LC BF = biodegradable fraction expressed on a VS basis 0.83 – 0.028 = Empirical Constant LC = Lignin content of VS, expressed as a % by wt. Production of Odor • Develop when SW stored for long periods of time on – site • More significant in warm climates • Typically, results from the aerobic decomposition of the organic components found in MSW. Breeding of Flies • In warm climate, it is an important phenomenon. • Flies develop in less than two weeks. • Maggot (larval) once develop, difficult to remove, & can develop to flies. Types of Solid Waste Collection System Collection System • After the generation, the solid waste is picked up according to a collection system. • In the last decade several systems are used for the collection of solid waste. • A variety of equipment used for the solid waste collection Types of Collection systems • Collection systems may be classified w.r.t. • Mode of operation • The equipment used • Types of waste • Mode of operation • According to mode of operation, the collection system classified into two categories viz ; • Haul Container System (HCS) • Stationary Container System (SCS) Haul Container System (HCS) • These are collection systems in which the CONTAINERS used for the storage of waste are: • Hauled to the disposal site • Emptied and • Returned to their original location or some other location. Types of Haul Container System • There are three main types of Haul Container Systems: • Tilt-frame Container Systems • Trash-trailer. • Hoist-Truck Stationary Container System • These are collection systems in which the CONTAINERS used for the storage of waste are: • Remain at the point of generation, except for • Occasional short trips to the collection vehicle for empty. Types of Stationary Container System • There are two main types of Stationary Container Systems: • Systems in which Self loading compactors are used • Systems in which Manually loading vehicles are used Labor Requirement HAUL CONTAINER SYSTEM (HCS) • Single collector is used • For safety (in some cases) driver and helper are deployed • For hazardous waste driver and helper always be deployed Stationary Container System (Mechanically Loaded) • Single collector is used • For container mounted on roller, driver and helper are brought into play. • In congested ,inaccessible locations driver and two helpers are used Stationary Container System (Manually Loaded) • Number of collectors varies from 1 to 3. • Single collector for curve and alley service generally used. • Multi person crew is used for backyard carry service. Comparison of HCS & SCS w.r.t. Merits & Demerits Composting Composting is an anaerobic process in which the micro-organisms, in an oxygen environment, decompose the organic food waste as a result minerals and humus are obtained as a final product. Key Inorganic Nutrients • nitrogen • phosphorus • sulphur • potassium • magnesium • calcium • sodium Process Requirements • Key Inorganic Nutrients • Temperature • Moisture content • Oxygen • C/N ratio • Microbes • pH • Biochemical composition and texture Temperature • Psychrophilic -20 ° to 10 ° C • Mesophilic 20 ° to 45 ° C • Thermophilic 45 ° to 112 ° C Moisture content • Compost should be kept moist, but not soggy • At the ideal moisture level, 50-60% Oxygen • Optimum oxygen levels are 15 to 20 per cent At the ideal moisture level, 50-60% • Composting inhibits at oxygen less than 10 per cent (by volume). • Turning and ventilating compost are meant to keep the oxygen content at a sufficient level. C/N Ratio: • Nitrogen is required for cell synthesis. • Carbon is used as energy source • Optimum C/N ratio is 30 • Composting operates down to C/N Ratios of 20 • Materials that are a good source of nitrogen are called "Greens” • Materials that are high in carbon are called "Browns Microbes: • Psychrophiles - the low temperature bacteria • Mesophiles - the medium temperature bacteria • Thermophiles - the high temperature bacteria PH • optimum pH range is 6 to 8 • Biochemical composition and texture: • composition of waste influence the process rate • Reducing the particle of the raw material will in crease the rate of composting. Composting systems • Traditional Wind-row. • Aerated static pile • In-Vessel Composting Environmental Benefits • Compost enriches soils • Compost helps cleanup contaminated soil • Compost helps prevent pollution • Using compost offers economic benefits Problem with Composting • Heavy Metals • Mercury • Cadmium • Copper • Zinc Worm Composting • Worm composting is using worms to recycle food scraps and other organic material into a valuable soil amendment called vermicompost, or worm compost. Worms eat food scraps, which become compost as they pass through the worm's body. Compost exits the worm through it’s' tail end. This compost can then be used to grow plants. To understand why vermicompost is good for plants, remember that the worms are eating nutrient-rich fruit and vegetable scraps, and turning them into nutrient-rich compost. Design of Sanitary Landfill Site Site Preparations The following steps should be taken immediately for the detail design of the proposed site and are essential to develop and start the actual treatment process. • Topographic survey of the site. • Detail leveling of the site. • Contour plan. • Cutting of the 150mm top soil of the whole area and saving it for earth cover over the solid waste. • Preparing site for proper drainage of rain water by cutting of high level ground and giving it a down slope (1:400) soil obtained from this cutting is used in providing embankment for fencing of the area. • Construction of all weather roads of 5m width, to facilitate easy approach of trucks to all points at site. • Providing infrastructure with all accessories, a watchman hut with attached toilet, Weight Bridge, wash trough (3 x 5 x 10m) and a vehicular as well as a pedestrian entrance gate. • Proper fencing on the top of the embankment towards the exterior side. Parameters Adopted for Design • All the calculations will be based on the population of the city and the same can be projected for the land requirements till the end of the design period. • It is considered that 30% of the waste generated is land filled, 60% is composted, while the remaining 10% is recycled. • Waste will be compacted in four layers, one below the ground level and three above the ground level. Depth of each later will be 2m. • Excavated soil will be used as cover material. • Cover will be 0.15m for intermediate layers while final layer will be covered by 0.6m (2ft) of cover material. • Excavation for one year will be made in advance • A bond will be provided in each layer after one year. • Waste will be compacted to density of 1000 to 1300 Kg/m3. • Embankments will be provided at the periphery, high enough to enclose the site with the fencing mounted on top. • One standard size of cell will be adopted considering the width of the compactor and the tractor blade.