Bio-fertilizer - A-View

advertisement

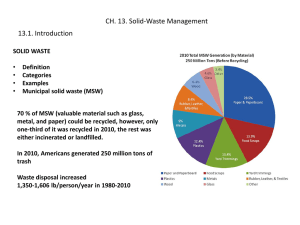

Geena Prasad What is Solid Waste? Solid Waste (also referred to as rubbish, trash, refuse, garbage, or junk) is unwanted or unusable materials. What is Solid Waste Management? SWM is the control of generation, storage, collection, transfer and transportation, processing and disposal of solid wastes. This includes all technological, financial, institutional and legal aspects involved to solve the whole spectrum of issues related solid wastes Objective: Reduction in generation and proper disposal.. 2 Major types of SW Municipal Waste Hazardous Waste Biomedical Waste Electronic Waste 3 4 Classification of SW Classified into two • based on source of generation • based on type Classification based on Source •Residential •Commercial •Institutional •Municipal •Industrial •Agricultural 5 Classification based on type Biodegradable Non-biodegradable consist of organic matter and can be degraded consist of inorganic and recyclable materials which cannot be degraded Paper, food waste, vegetables and fruit peels, wood, etc. Plastics,Glass,Metals 6 Classification of solid wastes Type Description Source Garbage Wastes from the preparation, cooking and serving of food, market refuse, waste from the handling, storage, and sale of produce and meat. Households, institutions and commercial concerns such as hotels, stores, restaurants, market, etc Combustible & noncombustible Combustible (primarily organic) paper, cardboard, cartons, wood, boxes, plastic, rags, cloth, bedding, leather, rubber, grass, leaves, yard trimmings etc. Ashes Residue from fires used for cooking and for heating building cinders 7 Classification of solid wastes Type Description Source Bulky wastes Large auto parts, tyres, stoves, refrigerators, other large appliances, furniture, large crates, trees branches, stumps etc Streets, sidewalks, alleys, vacant plots etc. Street sweepings, dirt, leaves etc. Street wastes Dogs, cats, rats, donkeys etc. Dead animals Abandone Automobiles and spare parts d vehicles Constructi Roofing and sheathing scraps, rubble, broken on & concrete, plaster, conduit pipe, wire, insulation demolition etc wastes Construction and demolition sites 8 Classification of solid wastes Type Description Source Industrial wastes Solid wastes resulting from industrial processes and manufacturing operations, such as food processing wastes, boiler house cinders, wood, plastic and metal scraps, shaving etc. Factories, power plants etc Hazardou Pathological wastes, explosives, radioactive s wastes materials etc. Animals & Manure, crop residues etc. agricultur al wastes Households, hospitals, institutions,stores, industry etc Livestock, farms, feedlots and agriculture Sewage Coarse screening grit, septic tank sludge, treatment dewatered sludge. residue Sewage treatment plants and septic tanks. 9 Degeneration Time-Solid Wastes Category Type of waste Approximate time taken to degenerate Organic waste such as A week or two vegetable and fruit peels, food waste etc Biodegradable Non-biodegradable Paper Upto 30 days Cotton cloth 2-5 months Woollen items 1 year Wood upto15 years Tin, aluminum, and 100-500 years other metal items such as cans Plastic bags One million years? Glass bottles Undetermined 10 Functional elements associated with SWM Waste generation Waste Storage Waste collection Transfer & transport Processing Disposal of final rejects 11 Composition of Municipal waste SWM Activities-2 major areas SWM Social Engineering Technological Interventions 13 Solid Waste Management in India • SWM is the primary responsibility and duty of the Urban Local Bodies • Direction from Supreme Court - MoEF issued Municipal Solid Waste (Management and Handling) Rules, 2000 • These rules stipulate various steps and standards for achieving effective SWM 14 SWM In India-contd.. CPHEEO estimation- Per capita waste generation 200 to 600 gm/day CPCB: collection coverage is 50 to 90% and 94% of the collected waste disposed of without scientific management practices 15 Some Facts about MSW in India There are 4,378 cities and towns in India Total urban population : 28.5 crores 423 are class I cities (population exceeds 1 lakh) These contribute more than 72% of the total MSW 16 Waste Generation in Class1 Cities Type of cities Waste generatedTonnes/day % of total garbage The 7 mega cities 21,100 18.35 The 28 metro cities 19,643 17.08 The 388 class 1 towns 42,635 37.07 Total 83,378 72.50 17 Status of SWM in Kerala LSGIs Waste generated- % of total waste Tonnes/day Corporations 1069 18.19 Municipalities 683 11.62 Gr. Panchayats 4126 70.19 Total 5878 100 18 Waste Generation Information on waste quantity and composition is essential for formulating SWM plan for any city Factors affecting waste generation Location Climate Socio-economic factors 19 Waste Characteristics Physical •Density of waste •Moisture content •Size Chemical Lipids Carbohydrates Proteins Natural fibres Synthetic organic materials Non-combustibles etc. 20 Waste Collection, Storage & Transport The factors that influence the waste collection system Record keeping & Documentation Transfer Station Collection points Collection frequency WASTE WASTE COLLECTION, COLLECTION, STORAGE STORAGE &&TRANSPORT TRANSPORT Collection Vehicle Routing Storage containers Collection crew Collection Vehicles Collection route Collection points Residential Commercial Industrial Collection Frequency Climatic conditions and requirements of a locality Containers Costs Storage Activities associated with the handling of SW until they are placed in the containers used r storage before collection ON-SITE STORAGE: Factors considered: 1. 2. 3. 4. 5. Types of containers used Container Locations Public health Aesthetics Methods of Collection Segregation at source Collection crew The size of the collection crew depends on The size and type of collection vehicle used Space between the houses Waste generation rate Collection frequency. Various management arrangements, ranging from municipal services, using self help groups to franchised services are prevailing for waste collection. Kerala, one of the pioneering states that implemented the decentralization of power to local governments has initiated many models in collection of solid wastes from the sources to the transportation points using the Self Help Groups, known as Kudumbasree groups, formed under the State Poverty Alleviation Mission. Kudumasree groups are involved in collection of wastes Waste Collection Separate vehicles have to be employed to transport the biodegradable waste & mixed nonrecyclable waste. All waste to be collected from collection points within 24 hrs. There can be many deficiencies in the collection system, the main deficiency being spillage during loading operations and collection on need basis. Collection Vehicles The collection vehicle could be a motorized vehicle, a pushcart or a trailer towed by a suitable prime mover (tractor, etc). The collection vehicle selected must be appropriate to the terrain, type and density of waste generation points, the way it travels and type and kind of material It also depends upon strength, stature and capability of the crew that will work with it. The collection vehicle may be small and simple (e.g., two-wheeled cart pulled by an individual) or large, complex and energy intensive (e.g., rear loading compactor truck). Small-scale collection generally used in rural hilly areas These can be small rickshaws, carts or wagons pulled by people or animals, and are less expensive, easier to build and maintain compared to other vehicles They are suitable for densely populated areas with narrow lanes, and squatter settlements, where there is relatively low volume of waste generated Non-compactor trucks Non-compactor trucks are efficient and cost effective in small cities and in areas where wastes tend to be very dense and have little potential for compaction Compactor vehicles The vehicles equipped with hydraulic loading arm hook the bins and unload the waste into the vehicle compartment The manual handling of waste is avoided Collection route Proper planning of collection route helps conserve energy and minimize working hours and vehicle fuel consumption. It is necessary, therefore, to develop detailed route configurations and collection schedules for the selected collection system. Barriers, such as railroad, embankments, rivers and roads with heavy traffic, can be considered to divide route territories Routing (network) analyses and planning can be done using the detailed maps prepared using remote sensing data and GIS Collection Vehicle Routing Efficient routing of solid waste collection vehicles can help decrease costs by reducing the labour expended for collection. Transportation of Waste Compactors and properly covered dump trucks were to be utilized to transport the waste to the landfill site. Separate vehicles were to be employed for transportation of biodegradable waste and mixed recyclable waste. Compactor loaders directly lift the bin, unload the waste and replace it in the original position. Choice of vehicle depends on the access roads to individual sites. Dump trucks are fitted with hydraulic equipments which enable them to unload waste without the help of manual labour. Record keeping and Documentation Records of personnel and quantities of wastes collected are useful in determining the efficiency of the personnel and in correlating waste quantities with conditions in the service area. A time keeping system at the transfer or disposal site is a key element in improving the efficiency of collection system and planning an upgraded system Technological Options 2 • Thermo-chemical Conversion • Pyrolysis & Gasification • Plasma Pyrolysis • Refuse Derived Fuel (RDF) 39 Composting • Composting is the biodegradation of organic matter like food waste, vegetable waste, garden waste etc – producing humus • The decomposition is performed by micro-organisms, mostly bacteria, but also yeasts and fungi. • Composting proceeds through 4 phases 40 Composting 1. Mesophilic phase-upto 40oC 2. Thermophilic phase-upto 70oC 3. Cooling phase 4. Maturation phase 41 Different types of Composting Windrow Aerated static pile In-vessel composting Vermi composting 42 Windrow Composting Windrows are defined as regularly turned elongated piles, trapezoidal in cross section. Size of Windrows- upto 2m high and 6m wide. Optimum size and shape depends on the particle size, moisture content, pore space and decomposition rate 43 Aerated Static Pile Composting Networks of pipes are connected to a blower which supplies the air for composting A controlled air supply enables formation of large piles, saving land space. Traps or filters control odours from the exhaust. Compost production takes about 6 to 12 weeks. 44 In-vessel Composting System The feedstock is enclosed in a vessel that provides adequate mixing, aeration and moisture. Vessel either rotates or is stationary, where a mixing mechanism moves the material around. Advantage: all environmental conditions can be controlled to allow rapid composting. It requires further curing after the material has been discharged from the vessel 45 Vermi Composting • It is the breakdown of organic matter by some species of earthworm • Kitchen wastes except oily and spicy items are suitable. • Material sprayed with pesticides, high water content materials etc are not suitable. 46 Biomethanation Methanogenic bacteria breakdown the organic material under anaerobic condition and produce methane and carbon dioxide. The effluent after digestion is a rich source of nutrients and can be used as a fertilizer. Bio gas unit - fixed dome model 47 Types of Digesters Single-stage digester standard rate digester high rate digester Two-stage digester Biogas Plants in India Floating drum type Fixed masonry dome type 48 Incineration It is a chemical reaction in which carbon, hydrogen and other elements in the waste mix with oxygen in the combustion zone and generates heat. Aim Volume reduction Stabilization of waste Recovery of energy from waste Sterilization of waste 49 Incineration Thermal degradation in the absence of O2 Can be used for MSW, tyres, plastics and biomass Char,oil and combustible gases are the products – Used for energy production End product is ash which must be landfilled Many types of Pyrolysis processes having different heating rates and maximum temperatures exist Choice depends on the type of mix of solid, liquid and gas required. Incineration Air is supplied to the waste Ash, tar and a gas product are formed Gas is utilized by direct combustion to produce heat or steam for electricity Gas can be unclean and hence furnace must be designed to tolerate this Gas can have varying compositions, hence furnace must be able to handle this. Plasma Pvrolysis This technology gasifies matter in an oxygen-starved environment to decompose waste materials in to its basic molecular structure. It uses high electrical energy and high temperature created by an electric arc gasifier. This arc breaks down waste primarily into elemental gas and solid waste in a device called plasma converter. 52 Refuse Derived Fuel (RDF) It is usually densified into pellets through the process of pelletisation. The calorific value of RDF pellets can be around 4000 kcal/ kg Enriched fuel may feed for other thermochemical processes like Pyrolysis/ Gasification, apart from Incineration pellets can be conveniently stored and transported. Recycling Programme Recycling is reprocessing of used materials Increases the economic value of the waste Reduces quantum of waste to be disposed. 54 Important Recycling Material: Advantages and Drawbacks Material Advantage Aluminum Batteries Concrete and demolition waste Drawbacks Aluminum has a high market value. Aluminum recycling requires significantly less energy than producing aluminum from ore. Recycling recovers valuable heavy metals such as lead, cadmium and mercury. Large variation in type and size of batteries requires specific recycling processes. Demolition waste can be crushed to gravel and reused in road construction and landscaping. Recycled waste is valuable only if there is a lack of other construction material. Separate collection is important. Recycling is suitable only if a processing plant is available. 55 Important Recycling Material: Advantages and Drawbacks Material Glass Advantage Organic waste Other metal Use of recycled glass saves energy compared with processing raw material. Can be recycled indefinitely because it does not deteriorate from reprocessing. Most commonly recycled by composting or anaerobic digestion. Scrap metal has a high market value (especially steel, copper, silver and platinum) and can be recycled indefinitely. Drawbacks Broken glass can contaminate and eliminate opportunities for recycling. Though compost is very beneficial to depleted soils, it still has a low market value. High-value metals (such as copper and silver) are incorporated in electronic devices, but extraction can cause severe environmental impacts. 56 Important Recycling Material: Advantages and Drawbacks Material Paper Advantage Polyethyle ne terephthal ate (PET) Other plastic Electronic waste Paper can be easily recycled; quality deteriorates. Recycled paper requires less energy. PET can be recycled if segregated from other waste. PET has a high market value if processing plants are available. Such as polyethylene or polyvinyl chloride, can be recycled but has less value Electronic waste (such as computers or mobile phones) contains high value metals. Electronic items can be dismantled, reused or recycled. Drawbacks Appropriate technologies with circular processes are required to protect the environment. More ‘downcyling’ than recycling occurs because quality decreases with every processing cycle. Recycling requires specific machinery Metals are often covered with polyvinyl chloride or resins, which are often smelted or burned, causing toxic emissions. 57 Common Types of Plastics that may be recycled Sl.No Chemical Name Abbreviation Typical uses 1 Polyethylene terephthalate PETE Soft drink bottles 2 High-density polyethylene HDPE Milk cartons 3 Polyvinyl Chloride PVC Food packaging, wire insulation and pipe 58 Common Types of Plastics that may be recycled Sl.No Chemical Name Abbreviation 4 Low-density polyethylene LDPE 5 Polypropylene PP 6 Polystyrene PS 7 Mixed plastic Typical uses Plastic film used for food wrapping, trash bags, grocery bags, and baby diapers Automobile battery casings and bottle caps Food packaging, foam cups and plates, and eating utensils Fence posts, benches and pallets 59 Sanitary land Fill Sanitary land fill is a systematic disposal technique especially for the rejects after processing on daily basis. 60 Essential Components of landfill liner system at the base and sides of the landfill leachate collection and control facility gas collection and control facility final cover system at the top of the landfill surface water drainage system environmental monitoring system closure and post-closure plan 61 LAND FILL - CROSS SECTION OF BOTTOM LINER 63 Introduction Source- Municipal Solid Waste of Thiruvananthapuram Municipal Corporation (TMC) TMC is carrying out door to door collection of segregated waste during morning hours through Kudumbasree It is then transferred to the closed trucks at specific transfer points at scheduled time and finally transported to the processing site at Vilappilsala. 64 65 SWM plant at Vilappilsala Maximum capacity of the plant is around 300 tons per day The plant consists of fully roofed compost yard, sieving machines, maturity yard and packing yard The plant has a built up area of 60,000 sq ft and another 25,000 sq ft area will be added shortly. There is a weigh bridge that is used to weigh all vehicles coming to the plant. A laboratory is attached to the factory 66 Method adopted Windrow Composting biodegradable wastes are allowed to form a windrow, which has trapezoidal shape, in the specified area by using excavator (Hitachi). The size of a windrow will depend on the nature of the material being composted, and the reach of the machinery or people available for making and turning it The size of the windrow is 18 x 4 x 1.8 m Distance between two windrows is 1.5m 67 68 Compost Plant 69 70 Compost to product The next step is mechanized sieving and the main parts of the machine are: Feeder Conveyor (Feeding compartment) Primary Separation Unit (First Trommel) – First rejection belt – First product conveyor Refining trommel i.e. Second trommel – Second rejection belt – Second product conveyor Common rejection belt Hydraulic power packs 71 Line diagram of Mechanised Composting (Level 1) at Vilappilsala, Thiruvananthapuram 2nd product conveyor 2nd Trommel 1st product conveyor 1st Trommel 2nd rejection belt Feeder Conveyor Municipal Solid Waste 1st rejection belt Semi Product Common rejection belt 72 Line diagram of Mechanised Composting (Level 2) at Vilappilsala, Thiruvananthapuram Chute Rejection belt Trommel To landfill Semi Product Product conveyor Bio-manure 73 Manure After 45 days, the biodegradable waste becomes fine, fluffy, earthy material without any putrefying smell It is used as a good soil amendment It has good water holding capacity It makes soil more porous It is a rich source of humus 74 75 76 Solid Waste Disposal Landfill: TVM Corporation Waste Management Plant - VILAPPILSALA 77 Landfill 78 Auto used for door-to-door collection Containerized pushcarts used for door-to-door collection 79 Road Sweeping machine Closed truck (locally designed) 80 Application of GIS in SWM Site Suitability Analysis Suitable location for solid waste processing plant and/or land filling Suitable location for solid waste Suitable location for solid waste storage, Designing short routes for waste collection Creating databases for households that pay and those who have not paid for the services Arranging time tables for trucks to collect waste and monitoring the truck movement Thank You