Sten Verhaegen Ontwerp van een flexibele

advertisement

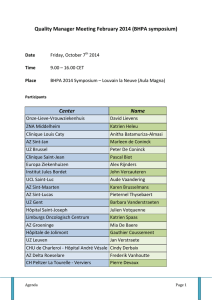

Ontwerp van een flexibele productie van inlegzolen Sten Verhaegen Promotoren: Jurgen Ceuppens, dhr. Marc Timmermans Masterproef ingediend tot het behalen van de academische graad van Master of Science in de industriële wetenschappen: industrieel ontwerpen Vakgroep Industrieel Systeem- en Productontwerp Voorzitter: prof. Kurt Stockman Faculteit Ingenieurswetenschappen en Architectuur Academiejaar 2013-2014 Masterproef Sten Verhaegen Abstract J. De Beukelaer nv - Débé is een producent van voornamelijk vlakke inlegzolen. Ze produceren 3 types van inlegzolen: kunststof, leder en licht gevormd. Daarbuiten produceren ze nog een reeks van hulpstukken om het comfort van uw zool te verhogen. Door gebruik te maken van eenvoudige productietechnieken zoals kappen en lijmen gecombineerd met handenarbeid verkrijgen ze een flexibel productieproces waarin veel variatie mogelijk is. Kunststof materiaal komt binnen als rollen gelamineerde stof volgens de gewenste samenstelling. Deze rollen worden vervolgens volautomatisch gekapt, uitgenomen en verpakt. De lederen zolen worden handmatig gekapt omdat de fouten in het leer er uit gehaald moeten worden. Nadien wordt er een onderlaag verlijmd. Als laatste kan er nog een voetbed of hulpstuk onderaan de lederen of kunststof zool toegevoegd worden om het comfort te verhogen. Het doel van dit onderzoek is om de productie van Débé uit te breiden naar gevormde zolen. Tijdens dit onderzoek is het belangrijk om te gaan kijken naar nieuwe materialen en technieken die toegepast kunnen worden en daarbij de flexibiliteit van de productie te behouden. In samenspraak met Débé zijn er 3 types van gevormde zolen gekozen waarover het onderzoek zal gaan: lichtgevormd model, model met veel details en een ondersteunend model. J. De Beukelaer nv 2013-2014 Universiteit Gent Iteratie 1 In de 1e fase werden er zonder al te veel voorkennis enkele concepten bedacht om zolen te kunnen vormen. Concept 1: Vacuümvormen op een aanpasbare mal. Concept 2: PU spuiten in goedkope mallen afkomstig van een modulair mastermodel. Concept 3: Persen van een thermoformeerbare schuimlaag met een aanpasbare stempel. Van deze concepten zijn enkele prototypes gebouwd die vervolgens zijn afgetoetst aan de eisen en wensen van het project. Op deze manier kwam het stempelen in een schuimlaag als beste concept naar voor Iteratie 2 Vooraleer het stempelconcept verder uitgewerkt wordt is het belangrijk om de gewenste resultaten duidelijk vast te leggen. Voor de lichtgevormde zolen was dit redelijk eenvoudig: een gekromde rand rond de hiel met verhoogde zones ter hoogte van de hiel en de bal van de voet. Bij het model met details komen hierbij nog eens vele kleine verhoogde zones kort op elkaar bij. Voor het ondersteunend model werden de verschillende belangrijke zones gedefiniëerd en hoe deze wijzigen volgens de maten. Aan de hand van deze analyse bleek dat de ondersteunende boog niet van vorm veranderd en enkel van maat. Daardoor kon er een mal ontworpen worden met een vast centraal stuk en verwisselbare voor- en achterstukken Het vaste centrale stuk werkte goed om de verschillende maten te produceren. Uit testen met deze mal is gebleken dat een 2-zijdige mal noodzakelijk zou zijn en dat een ondersteunend model enkel bestaande uit schuimmateriaal onvoldoende steun zal kunnen bieden. De combinatie met een voetbed is noodzakelijk. J. De Beukelaer nv 2013-2014 Om een geschikt materiaal te vinden om de zolen uit te produceren ben ik zoek gegaan naar een schuim dat zich makkelijk laat hervormen en goede eigenschappen bevat voor in zolen (schockabsorptie,hardheid,...) Zo kwam ik snel bij Polyethyleenfoams die al reeds gebruikt worden in de sportindustrie als bescherming. Met enkele stalen PE foam van Alveo heb ik de 1e testen kunnen uitvoeren. Universiteit Gent Iteratie 3 Tijdens de volgende stap in het ontwerpproces werden er 2-zijdige mallen ontworpen van zowel het ondersteunende model als het licht gevormde model. Deze mallen waren verder uitgewerkt om getest te kunnen worden in het productieproces van Débé. Met de nieuwe mallen werden niet enkel de stalen PE foam van Alveo gestest maar ook enkele nieuwe stalen die als basis PE foam hebben maar gelamineerd zijn met een onder- en/of bovenlaag. Beide types van foams gaven goede resultaten na kortstondig verwarmd en geperst te worden. Om de verhoogde zones ter hoogte van de hiel en de bal van de voet en de details te testen zijn er enkele kleinere teststukken ontworpen. De resultaten met deze teststukken bewezen dat een modulaire mal mogelijkheden biedt om de verhoogde zones te wijzigen in maat of te elimineren. Ook bewezen ze dat veel kleine details aanbrengen op een zool geen probleem vormt met deze techniek. Om het ondersteunend model af te werken werd er een eigen voetbed ontworpen dat perfect in de mallen past. Op deze manier kon aangetoond worden dat de combinatie van een ondersteunend voetbed met het vervormde PE schuim geen probleem vormt wanneer men eigen mallen ontwerpt en CNC freest in goedkope Polyurethaan schuimen. Eindresultaat Het eindresultaat is een productietechniek waarbij zonder al te veel wijzigingen in het huidig productieproces Débé gevormde zolen kan gaan produceren. Gelamineerde rollen PE foam worden gekapt zoals in het huidige proces. Deze gekapte vormen worden vervolgens kortstondig verwarmd en geperst in de mallen. Het opwarmen van het materiaal is nieuw maar de persen hebben ze al staan. De mallen worden intern ontworpen en CNC gefreesd in goedkoop hard PU om de kost te drukken. Door vanaf het begin deze mallen met de nodige intelligentie te ontwerpen kan er veel flexibiliteit en modulariteit ontstaan. J. De Beukelaer nv 2013-2014 Universiteit Gent Page | 1 Page | 2 Page | 3 Page | 4 Page | 5 Page | 6 Page | 7 Page | 8 Page | 9 Page | 10 Page | 11 Seriegrootte Kost Tijd Afwerkingsgraad Flexibiliteit in eigenschappen en vorm Maatbereik Spuitgieten Persmallen Hoog (massaproductie) Hoge investering Hoog (massaproductie) Hoge investering Snel Hoog Nee Snel Hoog Nee Mal voor elke maat Mal voor elke maat Orthopedische zolen Laag (1 series) Lage investering, veel handwerk Traag Hoog Ja Elk stuk is uniek Page | 12 Page | 13 Page | 14 Page | 15 Page | 16 Page | 17 Page | 18 Page | 19 Page | 20 Page | 21 Page | 22 Page | 23 Page | 24 Page | 25 Page | 26 Page | 27 Page | 28 Page | 29 Page | 30 Page | 31 Page | 32 Page | 33 Page | 34 Page | 35 Page | 36 Gewicht (0-5) Toelichting Zool Fysieke eigenschappen 4 Afwerkingsgraad Combinatie van materialen Proces Past in huidig proces Flexibiliteit in vorm Flexibiliteit in maat Kosten Tijd 3 4 5 4 5 3 3 Schokabsorptie hiel, steun in brug, energieoverdracht in bal Afgewerkt product of nabewerking nodig Kunnen alle materialen gecombineerd worden # aanpassingen aan huidig proces Vorm makkelijk aanpasbaar Maat makkelijk aanpasbaar Kost van investering en gebruikte materialen Doorlooptijd van grondstof tot afgewerkt product Page | 37 Page | 38 Page | 39 Page | 40 Page | 41 Page | 42 Page | 43 Page | 44 Page | 45 Page | 46 Page | 47 Page | 48 Page | 49 Page | 50 Page | 51 Licht gevormde zool Page | 52 Licht gevormde zool met details Het laatste model verschilt niet veel van het vorige. Dit model heeft ook een gevormde rand rondom de hiel. Het grootste verschil zijn de vele details op de zool. Zo zijn er niet enkel verhoogde zones bij de hiel en de bal van de voet maar de volledige zool bestaat uit verschillende verhoogde zones. Het doel van deze zool in het onderzoek is om na te gaan of de vorming van deze details mogelijk is met de nieuwe technieken. Page | 53 Page | 54 Page | 55 Page | 56 Page | 57 Page | 58 Page | 59 Page | 60 Page | 61 Page | 62 Page | 63 Page | 64 Page | 65 Procesgrenzen 3 Kwaliteit van de persing 2,5 0-1=Niet OK 1,5 Heating 1 Pressing 1-2= +/2-3=OK 2 Placement 0,5 0 10 20 30 40 50 60 Tijd (s) Page | 66 Page | 67 Page | 68 Page | 69 Page | 70 Page | 71 Page | 72 Page | 73 Page | 74 Page | 75 Page | 76 Page | 77 Flexible production of insoles – a case study Sten Verhaegen Jurgen Ceuppens Student Industrial Design Gent University Kortrijk, Belgium sten.verhaegen@ugent.be Teacher & Researcher Industrial Design Gent University - Industrial Design Center Kortrijk, Belgium jurgen.ceuppens@ugent.be Abstract—This paper focuses on the development of a flexible production process of insoles for J. De Beukelaer N.V., a producer of flat soles. It describes the search to a low cost manufacturing method, using new techniques and materials, with possibilities in shape, size and kind altering. Keywords—insole; flexibel production; low cost I. INTRODUCTION (Heading 1) J. De Beukelaer N.V. is a small KMO which is active in the insole industry. They produce mainly flat insoles. They feel the need to expand their product range to shaped insoles, going from simple aesthetic shapes to more functional supporting shapes. Because they use very simple production techniques and a lot of manual labor they have a very flexible production process and can produce a wide range of products with very little effort. This flexibility is the reason why they still can compete against larger mass producers. It’s key for the development of a new technique to produce these shaped insoles in a flexible way. II. J. DE BEUKELAER N.V. - DÉBÉ A. Types of insoles Débé produces three kinds of soles: Leather, synthetic and light shaped. The first two are completely flat soles were as the third is lightly shaped yet not as much as a full orthopedic insole. The leather soles consist of a top layer of leather combined with a bottom layer, accordingly to the wishes of the client. Mostly the bottom layer is made of latex for anti-skid properties. The synthetic soles already have the desired combination of top and bottom layers. They are produced by a company specialized in laminating fabrics and synthetics into big sheets of material. Those sheets are cut in the right size and shape by Débé to produce synthetic insoles. The properties of the soles can vary a lot from thermal protection, moist absorption to Kevlar protection in safety shoes. The light shaped soles are practically the same as the leather and synthetic flat soles. The only difference is the extra footbed that is added underneath the soles to give the sole its shape. B. Production method There are three production methods used to produce the insoles: Cutting, gluing and pressing. The synthetic soles are cut from large sheets in the desired shape and size using cutting dies. The production process can be either fully automatic for large series or semi-automatic for smaller series. After cutting the soles are ready for packaging and shipping. The leather soles are first cut from a sheet of leather into the desired shape and size using a cutting die. Unlike the cutting dies for the synthetic soles these cutting dies have to be placed manually on the sheets of leather. This is necessary to extract flaws in the sheets of leather. Then a bottom layer, which has been cut in the same shape and size, is glued to the leather sole by applying a layer of glue and pressure to the sole. The leather sole is now ready for packaging and shipping. The light shaped soles can be made of leather and synthetic materials. They are made in the same way as the flat insoles only a plastic footbed is glued and pressed to the bottom of the insole. This gives the sole its desired shape. C. Business structure 1. Internal structure To obtain a better view of the internal structure of Débé the different production processes and flows are analyzed. There are 3 main parts in the business structure: The management, the production leader and the production. Within the production there are again 5 parts: Cutting, assembly, stamping, packaging and shipping. All of these parts are connected with each other as visualized in the diagram below. The information flows mainly through the production orders. Because it’s a small company there’s also a lot of information passed by word of mouth. Production orders are specific for every step in the production process. These production orders go back and forth between the production workers and the production leader. Any mistakes or flaws are told by word of mouth. This way there’s no need for the products to pass through the production leader and he has a complete overview over the production. The second type of flow is the material flow. When a new production order is started, the production workers take empty plastic containers from the stock en place the production number on them. The products which are being produced are placed inside the containers. When a step in the production process is finished the containers go back to stock and the production order is returned to the production leader. He then hands out the next task in the production order to the same or another production worker. By reading the production order number the workers know which container they have to get from the stock to proceed to the next production step. III. FLEXIBILITY Fig. 1. Internal business structure The owner and his administration, the management, are the connection with the customers and suppliers and with the production leader. The management prints out production orders which contain information for every step in the production process for every type of sole. These production orders only get distributed to the production leader when the stock is ready. Before the production workers receive the production orders they pass through the production leader. He is the middleman between management and production. As the former owner of the company he knows every production process, material, time to produce,… and is very capable to plan all the production orders. His job is to have at all times a complete overview over the production. The production itself consists out of 5 parts as seen in the diagram. Insoles have to pass through all or some of these, depending on the type of insole, 5 parts to be completed. When a step in the production process is completed the production order is returned to the production leader. When he receives the final production order, the shipping order, he knows the products are ready. He then returns the filled out packing list to the administration. They now can check if all of the products of this customer are ready for shipment. 2. Information- and material flow Between the different parts of the company there are flows of information and flows of material (also flows of energy but these will not be discussed in this paper). By dividing the different flows we can see that the information, of products or processes, doesn’t necessarily needs to be connected to the materials. A. Mass production vs mass customization We can see an evolution of the manufacturing industry through different paradigms since its birth two centuries ago. First there was the “Craft paradigm” which creates products specific to the customers needs but at high cost. Secondly there was the “Mass production paradigm” which produces products in high volumes at low cost but with low number of varieties. The needs of customer are barely taken in consideration during this paradigm. The latest change in paradigm, due to global competition and consumer demands for high product variety, is called the “Mass customization paradigm”. During this paradigm manufacturers designed the basic product architecture and options while customers could chose the assembly combination they desire the most. Flexible and reconfigurable production processes are needed to create high variety in the final assembly stage. We now see a new paradigm rising that shifts its focus from the shareholder value to the customer value. This paradigm is called the “Mass personalization paradigm” and has its foundations in cocreating and co-designing with the customers from the start. This way customers have infinite amount of freedom to create products specific to their needs [1]. Fig. 2. Volume variety relationship in manufacturing paradigms [2]. B. Product variety More demanding customers and a global competition have led to mass customization production processes. This manufacturing technique has given customers personalized products at the price of mass produced products. Mass customization can be offered in two manners: product variety and process variety. Product variety is defined as the diversity of products that a production system provides to the marketplace [3]. Process variety is the diversity and complexity in the processes due to product variety and process alternatives for each product variant [4]. Product variety shouldn’t be infinite. Too many options can confront a customer with information overload, who uses simple heuristics which often aren’t optimal. Fewer options are therefore better but not at the expense of customer satisfaction. [5]. Product variety addresses the pursuit of efficiency from a product design perspective. By designing modular parts customized products are created while minimizing costs, delays, and internal complexity. [5]. C. Modularity Modularity is key to produce a wide variety of products at near mass production costs. Repetitive production of different components who can be combined in a number of varieties is the link between mass production and mass customization. Flexible manufacturing systems (FMS) can lower the cost of customization through the use of some sort of modularity in their design. Different types of modularity can be defined: Fig. 3. Modularity types (Ulrich and Tung, 1991) [6] D. Flexibility and modularity in Débé Flexibility in production is Débés greatest advantage and the reason why they still can compete with mass production companies. The reasons behind Débés flexibility are their very simple production techniques which are cutting, gluing and pressing combined with manual labor. All of the materials are imported as sheet material and then cut in the desired shape and size using cutting dies. The different layers can then be combined to form different types of soles. The modularity between different layers and their combinations make it possible for Débé to produce a high variety of products with little time, cost and effort. E. Criteria for flexibility in the project By analyzing the company’s current production process I have set some criteria that will help me through the design process. This way the process will remain flexible and it will be the most suitable solution for Débé. Combination of materials: Different kinds of materials are combined to offer a high variety of products Number of changes to current process: By lowering the number of changes to the current production Débé will be able to quickly adapt their process. This can’t influence the quality of the solution. Flexibility in size: Sizes 35 to 48 must be produced. Flexibility in shape: This project must be applicable to other shapes of insoles Cost: The cost of the new method must be as low as possible. IV. PROJECT A. Shape analysis Before a new technique could be developed it is import to know which shapes need to be created. The production technique should be applicable to a wide variety of shapes but still it’s necessary to have a concrete shape to start with. In concert with the company’s wishes and the demands we chose 3 types of insoles that are relevant for Débé at this moment: (1) Light shaped insole, (2) insole with clear heel and base marks and (3) a supporting insole. 1. The second type of insole is not so different from the first type. It also has a raised edge from the middle of the foot around the heel. The main characteristics are the many details on the center of the insole. They are a little bit thicker in comparison to the rest of the insole so they add a little bit of comfort but mainly they make the insole look better. These details are the focus in the research to produce this kind of insoles. 3. Supporting insole Light shaped insoles Fig. 6. Supporting insole Fig. 4. Light shaped insoles The first type of insoles, and the main reason this project was started, are the light shaped insoles. They fit a little bit better in your shoes and around your feet but they just look more complex and therefore better compared to the flat insoles that Débé produces at this moment. For this reason they want to expand their product range from flat insoles to light shaped soles. The main characteristic is the raised edge from the middle of the foot around the heel. At the heel and the metatarsus there are slightly thicker areas for more comfort. The location of these areas come from orthopedic studies but in this case they have barely any orthopedic use. 2. Insole with clear heel and base marks The final type of insole is a supporting insole. They can vary in shape and size and have a few similar properties such as the raised edge and thicker zones at the heel and metatarsus. Their main characteristic is their supporting qualities. A soft material on top is combined with a rigid footbed on the bottom. This combination gives the insole a comfortable feeling while supporting the arc of the foot. Insoles like this are the closest thing to orthopedic insole and are ideal for people with minor complains about their feet, joints, … everything that comes from a wrong stance. The focus with these insoles is the combination of the footbed and a soft material in one process. B. Material analysis Not only the shape of the insoles is import but also the type of material it’s made of. The material has to meet certain requirements in terms of manufacturability, comfort, properties and look. Before searching a suitable material a list of requirements was drawn up: Deformable in the desired shape Shock absorption for comfort Starch enough to keep its shape Breathable Moist absorption 1. Fig. 5. Insole with clear heel and base marks Concept exploration Before a type of material could be chosen, different general concepts needed to be tested. This is necessary because the material of the insole depends on the production process. In this primary phase of the design process 3 concepts were developed and tested. The first concept is to form insoles through cheap molds (silicone, plaster, …) via injection molding of Polyurethane (PU). PU can be altered in many properties so the requirements for insoles are met. To test this concept I casted a silicone mold from an existing insole and inserted it with liquid PU, combining the PU with a top and bottom leather layer. Fig. 7. Concept 1: Injection molding For these main reasons, and a few other, I picked the foam pressing concept for this case study. 2. Material exploration Now that the production technique is set I could start searching for a fitting material that has the requirements for insoles and could be formed by pressing. By searching different types of foam materials and meeting with people in this industry I quickly realized a thermo formable foam would be best to use in this concept. After some first tests with memory foam and Thermoplastic Polyurethane (TPU) I came across Closed cell cross-linked Polyethylene (PE) foams. This thermo formable foam is already widely used in the sport and leisure industry and has excellent shock absorbing properties. PE can be altered with different additives to make it softer, more flexible,… [7]. The foam material can be laminated with different top and bottom layers to meet the breathable and moist absorbing requirements. The second concept is to press a foam layer into the desired shape. The shape is created by using a molded surface and pressing it onto the foam. By combining different top and bottom layers before the forming of the insole the different layers can be cut in the traditional way. Fig. 10. Azote foams, sport and leisure applications [7] I received a series of PE samples with minor differences in properties. After heating and pressing these samples in a mold some very good first results came out. Fig. 8. Concept 2: Foam pressing The third and final concept is to vacuum form a thermoplastic plastic into the desired shape using a 1-sided mold. Again by combining different top and bottom layers before the forming of the insole the different layers can be cut in the traditional way. Fig. 9. Concept 3: Vacuum forming After comparing the 3 concepts the foam pressing concept gave the best results. It doesn’t need complex injection molds or any type of extruder to mix and insert the materials as the first concept. Foam also gives the best comfort and can easily be formed in comparison to the plastic from the last concept. Fig. 11. Samples PE foam After testing the PE foam material I recieved a few samples with different top and bottom layers but all with a core of PE foam. When heated and pressed these samples gave the same good results as the PE foam alone. Fig. 12. Samples laminated PE foam Because the material is shipped as laminated rolls it fits perfectly in the current production process of Débé. By altering the top and bottom layers they could produce a wide variety of shaped insoles with the same technique. C. Molding exploration To give the material the desired shape some sort of mold is necessary. From the beginning until the end of the project different types of mold are prototyped to test the forming of the insoles. 1. After testing with the first milled molds in low density PU it came to light that a 2-sided mold would be necessary to produce the desired shapes of insoles. Molds exploration At very early stages in the design process molds made from PU foam and coated with putty were used to test the forming of the material. Fig. 16. High density PU mold 2. Advantages of CNC-milling By designing the molds, in CAD programs, with flexibility and modularity in mind, CNC-milling provides all the necessary tooling to create pressing molds. Combining these possibilities with internal CNC-milling, even at prototyping scale, very fast and very good prototypes can be tested and shown to customers. Fig. 13. Foam and putty mold Secondly I started exploring with the possibilities to divide molds and thus creating 1 centerpiece for all the sizes and different add-ons to alter the size and type of insole. Some details and modular parts were created and tested to show the possibilities with CNC-milling. Fig. 17. Detail testing molds Fig. 14. Plaster mold The first 2 types of molds were handmade or casted from existing insoles. Because future molds in the production process won’t always have a parent model and will have to have a certain precision I started exploring with rapid prototyping possibilities. Fig. 18. Detail testing results Molds could be created to combine plastic footbeds with PE foam. This way supporting insoles can be created using the same production technique Fig. 19. Footbed testing mold Fig. 15. Low density PU mold CNC-milling and 3D-printing, both flexible manufacturing techniques, would be able to produce molds that could be used to press insoles. The advantages of 3D-printing, undercuts and complex shapes, aren’t fully used in these molds, the range of materials is smaller and it’s more expensive. Therefore CNCmilling has been chosen as the production method of the pressing molds. A final test with CNC-milling is the creation of exchangeable parts to make a centerpiece with different addons to save material for different sizes and types. Fig. 20. Exchangeable parts in molds D. Implementation in the current process Tests with CNC-milled molds and laminated samples gave some very good results which is proof the technique works. Not only the technique is important in the project but also how this technique will work in the current production process. During the design process the current production process was kept in mind to minimize changes and costs. 1. Fig. 24. Separating line 2. Cutting The laminated PE foams are distributed as rolls, because Débé already has the infrastructure to cut roll materials using cutting dies a small test was set up. I cut a small piece of PE foam with the press and cutting die they use and there was no problem. Heating When the insoles are cut they have to be heated to become formable. The cheapest and easiest way to do this is with a convection oven. In this project I choose for a conveyor belt oven because it has many advantages: The temperature can be set, the speed of the conveyor belt can be set and the material can’t be heated too long. This is all necessary because different types of laminates may need different temperatures of heating times. Fig. 21. Die cutting test When the soles are cut in the desired shape they have to be placed in the molds by the production workers. By cutting the soles in pairs and keeping them together every pair comes from the same roll and from same position on that roll. This maintains the quality if the insoles. To choose a cutting pattern which has the best handling some different types were tested with the production workers Fig. 25. Conveyor belt oven 3. Pressing Heated pairs of insoles come out of the conveyor belt oven and can be placed inside the mold. Positioning holes in the cutting pattern make sure the soles are always on the right position. When the insole is placed the press can be closed and the material takes it shape while cooling down. Also here some adjustments can be made to the pressure of the press depending on the type of laminate. Fig. 22. Cutting patterns Fig. 26. Press and closed mold 4. Process boundaries PE foams (laminated or not) need a certain temperature to become thermo formable. Therefore I searched the boundaries of the material using a small oven set to 200 °C. With this test I could determine the minimum time for heating, the maximum time for placement and the minimum time for pressing/cooling. Fig. 23. Chosen cutting pattern After cutting and shaping of the insoles they have to be separated from each other before they can be packed and shipped. Different cutting patterns were tested to see which one was the easiest to be separated by hand. have to use by the number on the order. The oven is preheated and the forming can begin. When an insole is pressed they are placed again in boxes with the same production numbers. Fig. 27. Process boundaries test The final stage in the production process is packaging of the insoles. Again the production number tells the workers which boxes are needed. The insoles in the boxes are still contected with each other but the cutting pattern makes it easy to separate the pairs. When the insoles are split the leftover connecting piece is discarded en the insoles are put in their packaging. The production flow doesn’t change a lot, the use of production orders is kept and every step can be executed on its own. The main change is the introduction of CAD drawings and CNC-milling before the production and during the production the task of forming the insoles through heating and pressing. Fig. 28. Process boundaries schedule The data collected from the boundaries tests tells us the minimum time for heating is 40-50 seconds, the maximum time for placement is 20-30 seconds and the minimum time for pressing is 30-40 seconds. The test was executed with 1 form of PE foam therefore the results are given as a time span because the heating, placement and pressing times can change with the material types. These values give us an idea how long the process will take to produce 1 pair of insoles. 5. Production flow Starting from the analysis from the current production process I have been able to fit in the new technique with as few changes as possible. To begin Débé will have to introduce CAD drawings and CNC-milling into their company. The person who operates these programs and machines is from the highest importance because it’s only by smart designing the molds flexibility and modularity is created. This person will be in contact with the management, and maybe directly with the customers, to specify the shapes and needs off the molds. He will also make the first prototypes and test them with the production workers and consult with the production leader. When a mold is ready Débé has to decide if they want to produce their own molds or outsource this cost. When the molds are ready material can be ordered. Nothing changes here, an order is placed and the material is delivered as rolls. Now the production leader hands out the cutting order with all the information (cutting die, size, amount, time, …) needed to the worker. After cutting the pairs of insoles are stored in boxes with a production number on them. Pressing orders are handed out when the cut insoles have to be formed. The production worker knows which boxes they Fig. 29. Internal structure with new techniques V. CONCLUSION By introducing CAD software and CNC-milling in the production process every kind of shape of insole can be produced thus creating complete freedom. Because every insole is different a thorough analysis of the shape is necessary to design the molds as smart as possible. This way modular parts can be added or removed to create new insoles or shapes with the same mold. This combined with cheap PU materials creates flexible molds at a low cost. PE materials which can be thermoformed are imported as rolls and can be processed in the same way as the current process. Adding two steps in the process, heating and pressing, are the only changes in the production process. Every process can be executed on its own not depending on the previous processes. This way flexibility is kept. VI. [1] [2] [3] [4] [5] [6] [7] REFERENCES S. Jack Hu, Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization, Procedia CIRP, Volume 7, 2013, Pages 3-8 Hu SJ, Ko J, Weyland L, ElMaraghy HA, Lien TK, Koren Y, Bley H, Chryssolouris G, Nasr N, Shpitalni M, (2011), Assembly system design and operations for product variety. CIRP Annals-Manufacturing Technology, 60(2):715-733. Ulrich K (1995) The Role of Product Architecture in the Manufacturing Firm. Research Policy 24(3):419–440. Zhang M, Chen YJ, Tseng MM (2005) Distributed Knowledge Management for Product and Process Variety in Mass Customization. International Journal of Computer Applications in Technology 23(1):13– 30. Joanna Daaboul, Catherine Da Cunha, Alain Bernard, Florent Laroche, Design for mass customization: Product variety vs. process variety, CIRP Annals - Manufacturing Technology, Volume 60, Issue 1, 2011, Pages 169-174 Ulrich, K., Tung, K., 1991. Fundamentals of product modularity. Proceedings of the 1991 ASME Winter Annual Meeting Symposium on Issues in Design/Manufacturing Integration, Atlanta. Zotefoams, Sport and leisure documentation, http://www.zotefoams.com/downloads/SportsEN.pdf