Brochure - Module Solutions & Systems AS

advertisement

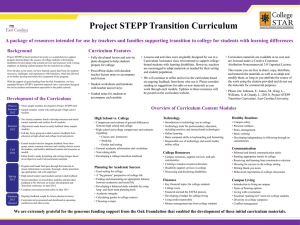

Al w od ol io .n o ng ns di ut fin es s ul ay m ne w so lu tio ns . o .n ns io ut ol es ul od m we can work it out Contents Module Solutions & Systems is an innovative provider of weight-saving modules, access solutions and passive fire & blast protection, to the oil and gas industry, including the renewable energy sector. The company 3 Our driving force 4 Our solutions 5 Our capabilities 6 Our areas of expertise 8 Modules 9 Rental solutions 10 Passive fire & blast protection 11 FRP Composite grating 12 Access solutions 13 Quality & HSE. References 14 References 15 The company 3 Finding the right solution is our driving force. Our driving force. MSS was established in Stavanger in 2001. Our senior employees have more than 25 years of experience within the oil and gas industry, covering areas such as project management, supply-chain management, architectural design, multidiscipline engineering, fabrication and installation. Finding the right solution is our driving force. All our business is based on the following values: being open, being trustworthy and building long-term relationships. Test module for PZV valves. Your requirements are special. We’ll give you the perfect solution. MSS has specialised expertise in the design and fabrication of modules and in lightweight solutions made of composites, and we deliver complete EPCI projects. Our solutions and systems are future-oriented, environmentally friendly, tailor-made to suit our clients’ needs and based on the best technology available. “One of our major assets is our ability to customise our solutions to the individual needs of our clients.” Kjetil Jacobsen managing director Our driving force 4 Our solutions 5 Module insulation work almost complete. HVAC system on module roof top. Our capabilities. Our range of capabilities: MSS provides engineering services for both modules and composite materials, from studies to complete solutions. The service can be provided in-house or at the clients’ premises. Over the years MSS has developed a core expertise in developing lightweight modules for existing platforms where space is limited. These projects are mainly turnkey in nature, including preparation of the footprint and final commissioning. Weight limitations are becoming a major problem on existing platforms when more equipment is required to support the operation. MSS carries out studies on existing structures on the feasibility of replacing steel with composite materials, which in some cases can reduce weight by up to 60 per cent and as a result increase the possible payload. Through our network of partners we have access to all the necessary disciplines to undertake full EPCI responsibility. The project teams are tailored to suit the project needs, with skilled personnel for all project phases. Offshore Surveys • Studies • Engineering • Consultancy Morten Alstadsæther business development director Our capabilities 6 EPCI MSS’s contribution – Input in the early phase to reduce overall project cost: Client “MSS is a unique centre of expertise, based on knowledge, experience and skilful employees.” • MSS’s contribution • Market needs • Standardisation • Best practice • Building methods a catalyst to improved solutions • Layout and design • Materials • Budget cost • Delivery time • General requirements • Surveys • Interface • Life-cycle cost • Installation methods • User-friendliness Partners Our range of capabilities 7 Our areas of expertise. Modules – with a focus on weight reduction. • Weight-saving modules – also for rental: accommodation modules, workshops, warehouses, laboratories, MSS has specialised in small and medium-sized projects. We deliver module solutions as single-lift, modular sections or flat-packed as prefabricated elements for all types of applications. The modules are available in steel, stainless steel and aluminium. The main focus is on weight reduction, due to the cost impact weight has on transportation, installation and support structures. co-ordination centres and restrooms • Passive fire & blast protection in composites • Grating, handrails and structures in phenolic FRP composite Our goal is to be the leading company in Norway within our core business area. Some would say we’re already there. Our areas of expertise 8 Typical applications: • Living quarters • Offices • Workshops • Warehouses • Laboratories • Zone 1 & 2 modules • Coordination centres • Rest rooms • Gymnasiums Modules 9 Rental modules – for a safe and comfortable workspace or living area. Well servicing Office Welding Hot work Accommodation unitsoffers a variety of modules modules modules modules MSS A60 accommodation and workspace modules for different applications. The modules are designed according to DNV 2.7-1, having ISO corners for fast and easy hook-up, and are built to the latest specifications. The modules can be customised to suit your requirements. Solutions portfolio Office modules Welding modules 10 MSS is Solent Composite Systems’ (SCS) strategic alliance partner in Norway. Solent Composite Systems has an unrivalled track record in the design and manufacture of ProTek™ jet fire and blast protection systems, which have been adopted for a wide variety of demanding applications in the offshore oil and gas sector protecting critical assets and personnel in hazardous areas including: Hot work modules Solutions portfolio Rental solutions Passive fire & blast protection – for hazardous areas. Accommodation modules • ESDV/Actuator protection • Fire and Blast walls and doors • Riser hang-off PFP • Marine fire partitions • TSR’s, escape-ways and refuge areas • Splash zone riser protection • Offshore modules The ProTek™ system comprises composite multi-layer structural panels mounted on a corrosion-resistant steel frame, providing an extremely lightweight rigid structure capable of managing severe blast and wind loads. The versatile modular design permits rapid on-site assembly to accommodate pipes, tubes, cables and other penetrations, even in very congested areas. Passive fire & blast protection 11 DURAGRID® pultruded bar grating meets the specific open-space requirements of NORSOK. FRP Composite grating – accommodating all your needs. Access solutions – unique, weight-saving and advanced FRP composite products. MSS is the largest supplier of composite grating to projects on the Norwegian Continental Shelf, representing Strongwell Inc. in Norway. We have supplied more than 60 000 sqm of FRP (fiber reinforced polymer) Pultruded Grating to both greenfield and brownfield projects. MSS are offering a high service level with respect to both high expertise within composites and delivery of grating from stock from our warehouse, to accomodate your needs. MSS is Pipex px® strategic alliance partner in Norway. Pipex px® engineer and manufacture advanced composite (FRP/GRP) structures and systems for both Offshore topside and Subsea markets. The main product is DURAGRID® Phenolic Grating manufactured by Strongwell with the following main advantages; • High strength • Low maintenance • Fire integrity • Superior anti-slip surface • Light weight • Patented profile locking system • Corrosion resistance • Good working comfort • High impact resistance The FRP Phenolic (topside) and FRP (fibre reinforced polymer) products are ideal for extreme environments offering high corrosion resistance, structural integrity and requiring minimal maintenance. FRP is also very light weight so offers huge benefits on Topside applications where overall load, balance and platform centre of gravity are so critical. For Offshore Topsides we can provide you with: • MARRS® Offshore Handrails, Ladders & Safety Gates • Access Structures, Platforms & Hop Up’s For Subsea we can provide you with: • Cocoon & Shroud® (protective subsea structure) • Impact Protection Panels • Subsea bridges • Cable Protection Systems (thermoplastic HDPE high visibly yellow) You may also have a requirement for bespoke products/solutions and we offer engineering services, design and specialist manufacturing for custom made projects. Composite grating 12 Access solutions 13 References Modules Quality & HSE MSS has an implemented and documented QHSE system in accordance with NS-EN ISO 9001:2008. Our management processes provide for: Continuous Improvements, Customer Satisfaction, Key Performance Indicators (KPI), Revisions and Management Review. MSS is using a web-based management system that allows our employees quickly and easily to access and contribute to our organisation’s documentation from any location where Internet access is available. All our processes and procedures required for the planning and safe execution of our business are defined and available through the management system. References FRP Composite grating Client Installation Period Description Norsk Hydro Aibel Aibel ConocoPhillips Aibel Statoil Aker Kvaerner Aker Kvaerner Aker Stord Aibel SMOE Kværner Kværner Grane Ekofisk Visund Ekofisk/Eldfisk Statfjord B/C Statfjord A/B/C Aker Barents Aker Spitsbergen Gjøa Gudrun Ekofisk 2/4-L Eldfisk 2/7-S Edvard Grieg 2003 2004 - 2008 2006 2004 - 2008 2006 - 2007 2006 - 2007 2007 - 2008 2007 - 2008 2008 - 2009 2011 2011 - 2013 2012 - 2013 2013 5000 sqm of 38 mm FRP Grating 3800 sqm of 38 mm FRP Grating 900 sqm of 38 mm FRP Grating 2400 sqm of 38 mm FRP Grating 1650 sqm of 38 mm FRP Grating 1350 sqm of 38 mm FRP Grating 2500 sqm of 38 mm FRP Grating 2500 sqm of 38 mm FRP Grating 5400 sqm of 38 and 45 mm FRP Grating 1500 sqm of 38 and 45mm FRP Grating 38mm FRP Grating and Accessories 45mm FRP Grating and Accessories 45mm FRP Grating and Accessories Other reference projects: Draupner, Frigg, Heidrun, Huldra, Island Innovator, Kårstø, Morvin, Oseberg, Polar Pioneer, Skarv, Schahin Drillship No.1, Tyrihans, Valhall, Transocean Searcher, Songa Dee, Snorre, Deep Sea Atlantic and Åsgard. Quality & HSE. References 14 Client Installation Period Description Siem Offshore Møkster Shipping Fabricom Seadrill Aker Reinertsen StatoilHydro StatoilHydro Aibel Aker Solutions Schlumberger Seawell Aibel Aibel Aibel Aker Solutions KCA DEUTAG Aker Reinertsen KCA DEUTAG Aker Solutions Aker Solutions Albatross Services Aker Solutions Archer Dolphin Drilling Dolphin Drilling Aker Solutions Aibel Aibel Aibel Aibel Aibel Odfjell Drilling Fabricom MS Siem Mollie MS Stril Møkster Gullfaks C West Epsilon Norne Njord A Njord A Ekofisk 2/4-J Gjøa Oseberg Gyda Ekofisk 2/4-J Njord A Oseberg C Draugen Oseberg East Åsgard A Kvitebjørn Visund Gullfaks B Songa Dee Gullfaks C Veslefrikk A Bredford Dolphin Bredford Dolphin Eldfisk 2/7-E Ekofisk 2/4-X Oseberg East Haven Ekofisk B11 Ekofisk 2/4-M Island Innovator Sleipner A 2007 2007 2007 2007 - 2008 2007 - 2008 2008 2008 2008 2008 2008 2008 2008 - 2009 2009 2009 2009 - 2010 2010 2010 - 2011 2010 - 2011 2010 - 2011 2010 - 2011 2011 2011 - 2012 2011 - 2012 2011 - 2012 2012 2012 2012 - 2013 2012 2012 2012 - 2013 2012 - 2013 2013 2013 Cold Storage Module Accomomdation Module Transformer Module (Flat Package) Coordination Centre 8 man Living Quarter Extension Restroom for Drilling Personnel Office Module Office Module Paint Shop & Waste Container Unit Office Module Hotwork Module Sanitary Module 7 man Office Module Mud System Operators Cabin Paint Shop Module Environmental Cabin Module Paint Shop Modules Storage Unit for Heavy Equipment Test Module for PZV Valves Freezer Room Module Gymnasium & Heliwait Module Wireline Tool Module Workshop Module Office & Gymnasium Modules LER-room Module Office Module Office & Collaboration Room Module Restroom for Drilling Personnel Storage Containers (4 ea) Containers for Nav. Aid Equipment (2 ea) Storage Container (Flat Package) Heavy Tool Storage Container Workshop Modules we can work it out Study and refurbishment Client Installation Period Description Aker Reinertsen Aibel Aibel Aibel Aibel Aibel Aibel Aibel Aibel Aibel Aibel Aker Solutions Aker Solutions Aker Solutions Aker Solutions Aker Solutions Aker Solutions Norne Ekofisk 2/4-J Ekofisk 2/4-J Eldfisk 2/7-B Ekofisk 2/4-X Eldfisk 2/7- FTP Eldfisk 2/7-A Eldfisk 2/7-B Ekofisk 2/4-E Ekofisk 2/4-K Eldfisk 2/7-E Gullfaks C Visund Valhall Visund Grane/Svalin Gudrun 2007 - 2008 2008 2008 2008 2008 - 2009 2008 2008 2008 2008 2008 2008 2009 - 2010 2011 2011 2011 - 2012 2011 2011 - 2012 Refurbishment of sky lobby and offices Study assistance – new office module Study assistance – new sanitary module Study assistance – rebuilding of warehouse Study assistance – new office and coordination centre Study assistance – new paint shop module Study assistance – new paint shop module Study assistance – new paint shop module Study assistance – new paint shop module Study assistance – new office modules Study assistance – new tool container Study assistance – new paint shop module Study – Module consept for 3 new modules Study – Prelim. Module Concept Design Study – Module concept for 3 new modules Phase II Study – Verification of new LQ Study – Weather Protection of FW Pumps (Composite) Complete reference lists are available at www.modulesolutions.no/references References 15 AD. MOMENT Foto: F. Ringe / Tom Haga Finding the right solution has been our driving force since 2001. MSS provides future-oriented, environmentally friendly and weight-saving modules, access solutions, passive fire & blast protection and well servicing rental units to the oil and gas industry. We have specialised expertise in the design and fabrication of all types of modules and in walkways and access solutions made of composites. MSS is co-owner of the companies Albatross Services and Albatross Electro & HVAC. The company group provides complete EPCI projects within the disciplines of mechanical, structural, piping, HVAC, refrigeration and electro, in addition to the repair and upgrade of drilling equipment. At present, the group employs more than 120 people at its locations in Stavanger, Bergen and Kristiansund. Font: Neo Tech Alt CMYK: C100 M57 Y0 K40 35% Module Solutions & Systems AS Skvadronvegen 22 NO-4050 Sola Tel. +47 51 71 69 20 www.modulesolutions.no