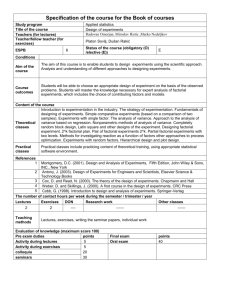

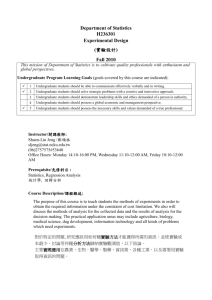

Design and Analysis of Engineering Experiments

advertisement

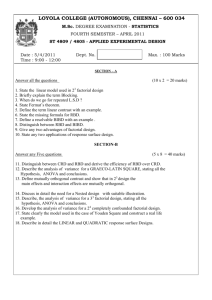

實驗設計與統計 胡子陵 立德管理學院資環所副教授 Leader University design and analysis of experiments 1 實驗設計與統計課程綱要及進度 Week1:Statistics (Review) Week2:Simple Comparative Experiments Week3:Experiments with a Single Factor:The Analysis of Variance(1) Week4:Experiments with a Single Factor:The Analysis of Variance(2) Week5:Introduction to Factorial Designs (1) Week6:Introduction to Factorial Designs (2) Week7:The 2K Factorial Design(1) Week8:The 2K Factorial Design(2) Week9:-----Mid-Term Report-------- design and analysis of experiments 2 實驗設計與統計課程綱要及進度 Week10:Blocking and Confounding in the 2k Factorial Design(1) Week11:Blocking and Confounding in the 2k Factorial Design(2) Week12:Two-Level Fractional Factorial Design(1) Week13:Two-Level Fractional Factorial Design(2) Week14:Fitting Regression Models(1) Week15:Fitting Regression Models(2) Week16:Response Surface Methods and Other Approaches to Process Optimization(1) Week17:Response Surface Methods and Other Approaches to Process Optimization (2) Week18:----Final Examination---------- design and analysis of experiments 3 實驗設計與統計 Part 1 – 前言 Chapter 1 課程目的 歷史回顧 一些基本原理(原則)和術語 實驗的策略 規畫、進行和分析實驗的方針 design and analysis of experiments 4 實驗設計介紹 An experiment is a test or a series of tests Experiments are used widely in the engineering world Process characterization & optimization Evaluation of material properties Product design & development Component & system tolerance determination “All experiments are designed experiments, some are poorly designed, some are welldesigned” design and analysis of experiments 5 解釋名詞 Response variable Explanatory variable Treatment Lurking variable Confounded Statistical significance:我們的結論有統計顯著 性,即證據或結果強到很少會光靠機遇(chance) 而發生。 design and analysis of experiments 6 工程上之實驗要求 Reduce time to design/develop new products & processes Improve performance of existing processes Improve reliability and performance of products Achieve product & process robustness Evaluation of materials, design alternatives, setting component & system tolerances, etc. design and analysis of experiments 7 實驗設計歷史發展的基本原則 Randomization Running the trials in an experiment in random order Notion of balancing out effects of “lurking” variables Replication Sample size (improving precision of effect estimation, estimation of error or background noise) Replication versus repeat measurements? Blocking Dealing with nuisance factors design and analysis of experiments 8 The meaning of Blocking Blocking(區集):一組實驗個體,這些個 體在實驗之前,就被認為在會影響反應的 某些地方很近似;與抽樣中的分層樣本具 有相同類似的功用。 Blocking design:將個體隨機分派到各處 理的此一步驟,是在每個Blocking裡個別 執行的。 design and analysis of experiments 9 實驗策略 “Best-guess” experiments Having a lot of technical or theoretical knowledge More successful than you might suspect, but there are disadvantages… One-factor-at-a-time (OFAT) experiments associated with the “scientific” or “engineering” method Devastated by interaction, also very inefficient Sometimes Statistically designed experiments Based on Fisher’s factorial concept design and analysis of experiments 10 因子設計 In a factorial experiment, all possible combinations of factor levels are tested The golf experiment: Type of driver Type of ball Walking vs. riding Type of beverage Time of round Weather Type of golf spike Etc, etc, etc… design and analysis of experiments 11 One-factor-at-a-time設計 Using the oversized driver, balata ball, walking, and drinking water levels of the four factors as the baseline. Optimal combination: regular-sized driver, riding, and drinking water design and analysis of experiments 12 因子設計 design and analysis of experiments 13 多因子之因子設計 design and analysis of experiments 14 多因子之因子設計-部份因子 design and analysis of experiments 15 實驗設計指南 1. 2. 3. 4. 5. 6. 7. Recognition of & statement of problem Choice of factors, levels, and ranges Selection of the response variable(s) Choice of design Conducting the experiment Statistical analysis Drawing conclusions, recommendations design and analysis of experiments 16 實驗設計歷史發展的四個時期 The agricultural origins, 1918 – 1940s R. A. Fisher & his co-workers Profound impact on agricultural science Factorial designs, ANOVA (analysis of variance) The first industrial era, 1951 – late 1970s Box & Wilson, response surfaces Applications in the chemical & process industries The second industrial era, late 1970s – 1990 Quality improvement initiatives in many companies Taguchi and robust parameter design, process robustness The modern era, beginning circa 1990 design and analysis of experiments 17 實驗中使用統計技術 Get statistical thinking involved early Your non-statistical knowledge is crucial to success Pre-experimental planning (steps 1-3) vital Think and experiment sequentially (use the KISS principle) design and analysis of experiments 18