1926.400 - Georgia Tech OSHA Consultation Program

advertisement

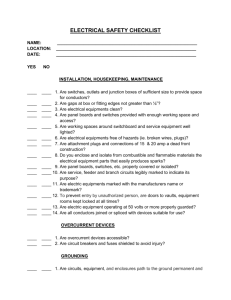

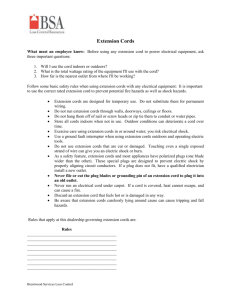

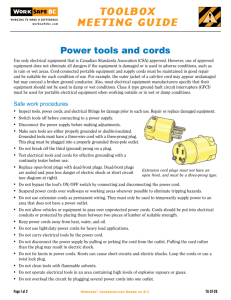

ELECTRICAL SAFETY TOOL BOX SESSION Georgia Tech Safety and Health Consultation Program INSPECTION, INSTALLATION AND USE OF ELECTRICAL EQUIPMENT • The following must be inspected before each use: – Electrical extension cords or temporary wiring, – any equipment connected by cord and plug, and – any portable electric hand tool. COVERS OR ENCLOSURES • All energized parts of electrical equipment or connections must be guarded to prevent accidental contact by a worker EXTENSIONS CORDS USED AS TEMPORARY WIRING • Extension cords used must be designed for the intended application • Plugs and the covering or electrical insulation material of the cord must be in good condition (no evidence of damage) • Extension cord plugs must always have a ground pin Ground Pin PROTECTION OF EXTENSION CORDS (TEMPORARY WIRING) • When run through holes, cords shall be protected from sharp edges • Never submerge extension cords in water • Do not expose cords to excessive heat, unless the cord has been designed for high temperature applications Ga Tech Safety and Health Consultation Program PLANNING THE WORK • Plan ahead to control any potential electrical hazard • The minimum working distance from overhead power lines is 10 feet • If you have to work at less than 10 feet from an overhead power line, then the electrical current must be disconnected ACCESS • Electrical extension cords used in the working area and in passage ways to the work area shall be installed so that: – they do not become a potential hazard for workers (tripping) – they are not physically damaged by traffic Ga Tech Safety and Health Consultation Program TEMPORARY ELECTRICAL RECEPTACLES • Shall be protected with approved covers • If metal covers are used, they shall be grounded WHAT IS A GFCI? • GFCI is a device that senses small imbalances in an electrical circuit caused by the electrical current leaking to ground. – If this imbalance occurs, the GFCI shuts off the electricity within a fraction of a second ASSURED EQUIPMENT GROUNDING PROGRAM • An assured equipment grounding program is allowed by OSHA but rarely put into practice due to: – The time required for an adequate implementation and follow up – The program may provide a false sense of safety INTRODUCTION This training information has been prepared by the Safety and Health Consultation Program at Georgia Tech with the technical collaboration of Mr. Juán C. Rodriguez and under the sponsorship of OSHA. Its content may be copied and distributed for free, and the only request made to the user is that Georgia Tech’s Safety and Health Consultation Program be acknowledged as the source. All information contained in this training is believed to be correct by the authors, but it is important to point out that, this is not an official OSHA publication and has not been revised or approved by OSHA. The user should be aware that the recommendations provided in this training do not replace any OSHA standard or regulation. Georgia Tech Safety and Health Consultation Program Georgia Tech Research Institute 260 14th Street, Fourth Floor Atlanta, GA 30332-0837 Voice : (404) 407-7431 FAX : (404) 407-8275 Web http://www.oshainfo.gatech.edu