Composite Materials & Polymer Matrix Composites Processes

Blade with Shear Web bonded to

Spar Cap

Upper (LP)

Spar Cap

Sandwich Shell Sandwich Shell

Trailing Edge

Leading Edge

Sandwich Shell

LE Shear

Web

TE Shear

Web

Sandwich Shell

Lower (HP) Spar Cap

2

Source:http://www.compositesworld.com/articles/wind-blade-manufacturing-targeting-cost-efficiencythrough-materials-based-strategies.aspx 4/5/2009

Blade Objectives

Figure from GE

Blade Objectives

• Maximize annual energy yield

• (limit maximum power)

• Resist extreme and fatigue loads

• Restrict tip deflections

• Avoid resonances

• Minimize weight and cost

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

UTS

Glass/X

Glass/poly ester

Carbon/e poxy

Birch/epo xy

880

700

1830

117

UCS

720

580

1100

81

UCS/sg

390

310

700

121

Fatique % of UCS

19

21

Stiffness/ sg

20

18

E/UCS^2

.07

.1

32 90 .12

20 22 2.3

Steel: fatigue and mfgblty

Blade Materials

• compressive strength-to-weight ratio,

• fatigue strength as a percentage of compressive strength,

• stiffness-to-weight ratio,

• a panel stability parameter, E/(UCS)2.

April 15, 2020 Courtesy: Nolet, TPI 8

Power, Length and Weight

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

Polymer Matrix Composites & Processes

General Composite Information

• Composites: 2 or more physically distinct phases

• Properties are better than the constituents

• High strength to weight ratio

• Also. . Corrosion, fatigue, toughness, surface finish

Why nots . . .

• (many have) anisotropic properties

• Polymer based may be subject to chemical attack

• Cost?

• Manufacturing process often slow and costly

(Groover p 177)

2 or more phases

• Matrix (primary phase)

– Polymer, metal, or ceramic

• Reinforcing agent (imbedded phase)

– Polymer, metal, ceramic, or element

– Fibers, particles, . . .

Possible combinations for 2 phases

Metal

Ceramic

Polymer

Element

Metal

PM infiltrate w/ 2 nd metal

Cutting tool

PM part w/ polymer

Fiber reinforced metals

Matrix

Ceramic n/a

SiC in Al

2

O

3 n/a n/a

Polymer

Steel belted tire

‘fiberglass’

Kevlar reinforced epoxy

Carbon fiber reinforced polymer

Fiber reinforcement

• Diameters of 0.0001 to 0.005 inches

• As D ↓, orientation ↑, probability of defect↓

– tensile strength↑ ↑

• Orientation:

– Unidirectional, planar, 3 dimensional

Fiber Reinforced Polymer Composites

• Short fibers:

– Open mold: spray up

– Closed mold processes

• Long fibers:

– Open mold: hand, automated tape machines

– Closed mold

– Filament winding

– Pultrusion

Materials

• Polymer matrix

– Thermosets: most common

– Thermoplastics

• Reinforcing

– Glass

– Carbon

– Kevlar (polymer)

Composing Composites . . .

• Molding compounds

– Mix short fibers and matrix

• Prepegs

– Fibers impregnated with partially cured TS matrix

– Allows fibers to ‘stay put’

– Continuous fibers

• Or done in the mold

Open Mold Process

• Spray up

– Requires mold

– Discontinuous fibers // random orientation

– Mixture of fiber and matrix deposited in mold

• Automated tape laying machine

– Requires mold

– Requires use of prepeg

– CNC control

Image sources: http://www.bauteck.com/manufacture/Manufacture2.htm 4/5/9 http://www.mmsonline.com/articles/getting-to-know-black-aluminum.aspx 4/5/9

Filament Winding

• Wound around mandrel or part of final component

• Continuous fibers

– Matrix added before or after winding

• Automation controls wrap pattern

Source:http://sacomposite.com/filament_winding_carbon_fiber.

html 4/5/9

Pultrusion

• Continuous fibers

• Dipped into matrix

• 2 options:

– Pulled through die and cured

– Laid up into an open mold (and later cured) http://www.tangram.co.uk/TI-Polymer-Pultrusion.html

Source: http://www.ale.nl/ale/data/i mages/Pultrusion.jpeg 4/5/9

Open Mold Processes

• Hand lay up

– Oldest, labor intensive

– Mold required

– Fibers placed in mold:

• Dry fibers placed and then matrix added

– Pour or brush or spray >> rolled to achieve mixture

– Vacuum used to ‘pull’ matrix into fiber

• Prepeg placed in mold

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

Source: www.tpicomposites.com 3/2008

Source: www.tpicomposites.com 3/2008

Source: www.tpicomposites.com 3/2008

Reusable Silicon Bag Technology for

SCRIMP

® o Silicone bags are rapidly fitted to the infusion tool o Feed lines, vacuum lines and embossed distribution channels are integrated into the bag improving the repeatability of the process (TPI Patented Technology)

April 15, 2020 Courtesy: Nolet, TPI 28

Fibers

• Woven Fabrics

– Higher cost, less applicable as structural components for blades

• Non-woven Multiaxials

– Most widely used in VARTM processes

– Low-cost, non-crimp form results in superior performance

– “Uni-directional”, Biaxial, Double Bias,

Triaxial and Quadraxial material forms available.

Courtesy of Saertex USA

Courtesy: Nolet, TPI 29 April 15, 2020

Resin Matrices

• Epoxies remain a primary resin of use in European based blade designs

• Vinyl-esters are attracting much interest by blade designers

• Polyester resins are still prominent in the industry.

• Thermoplastics and other matrices

April 15, 2020 Courtesy: Nolet, TPI 30

http://www.compositesworld.com/articles/carbon-fiber-in-the-wind.aspx

Blade Components

Infused Together

• Skin

– Composite

– Core

• Spar cap

– Composite

• Shear web

– Composite

– Core

• Root Section

– composite

Other Materials

• Bond paste

• Hardware

• Balance box

• Paint

• Lightening protection system

• Platform

Quality Issues

• Waves

– Aspect ratio (L/a)

• Bond failure

• Dry infusion

• Lack of continuous fibers

• Geometrical errors

• Fabric assembly errors

Figures from: “Yerramalli, Miebach, Chandraseker, Quek: “Fiber Waviness

Induced Strength Knockdowns in Composite Materials Used in Wind Turbine

Blades”. 2010

• Cut fabric

• Preforms

– Layup

– Infuse

– Inspect

– Trim

• Shell

– Layup

– Install preforms

– Infuse

Process Steps

• Assembly

– Shear web

– 2 shells

• Finishing

– Finish edges

– Wet layup

• Final cure

• Drill and cut end square

• Finishing and painting

• Hardware

• Balance box

• Final inspect

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

Burton, Sharpe, Jenkins, Bossanyi: “Wind Energy Handbook”

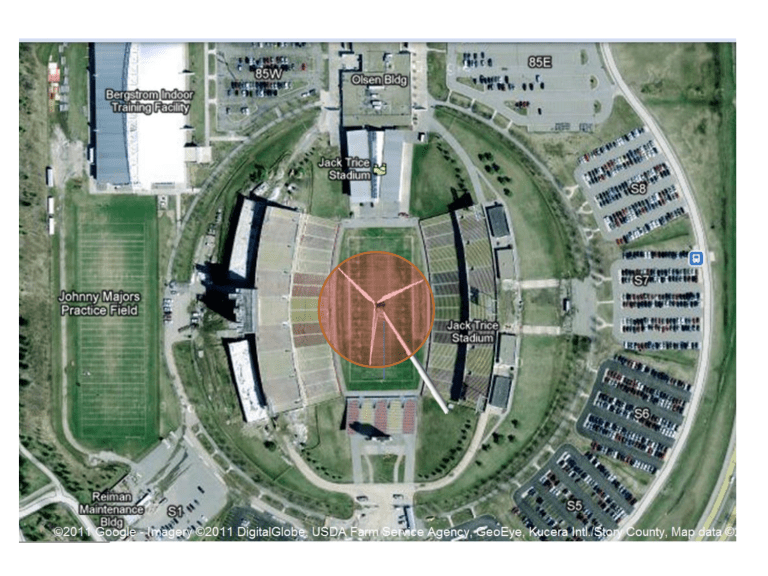

Mark Higgins 9/15/2011 Presentation at ISU

Mark Higgins 9/15/2011 Presentation at ISU

Mark Higgins 9/15/2011 Presentation at ISU

Mark Higgins 9/15/2011 Presentation at ISU

Mark Higgins 9/15/2011 Presentation at ISU

Mark Higgins 9/15/2011 Presentation at ISU

Assembly Variation

• Maintain +-mm across

50m assembly

• Joints are critical

43

Future Automation Systems?

Rapid Material Placement Systems

(RMPS)

Automated blade molding

Automated root end machining for wind blades

Machine adapts automatically to blade position

Machining processes: Sawing, milling, boring and trimming http://mag-ias.com/index.php?id=308&L=2

Options for Large(r) Blades

• Manufacturing

– Make at point of use

– Make in region of use

– Import

• Design

– Flatback design

– Design in 2 pieces

– Materials to reduce weight

Remote Blade Manufacturing Demonstration –

Sandia 2003