Pervukhin L

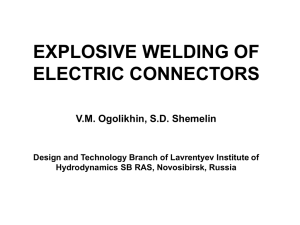

advertisement

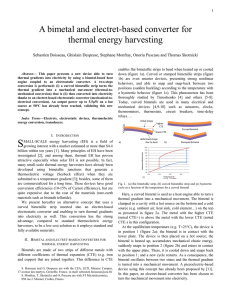

1.Industrial-scale production of clad metals by explosive welding in moscow area:technology and enviroment challenges Sidorov of M.I.1 , Vaginas of A.B.1 , Klimenko V.Yu.1 Pervukhin L.B.2 Denisov I.V.2 1-Federal state enterprise Geodeziya research institute, 2- LLC "Bitrub International” 2. Market of clad metals in Russia and abroad: dynamics and trends in 2013 Agaurov S.Yu, Chernobai Yu.P, and Bochkarev A.A. Metal Market Co.Ltd, Moscow,109428, Russia 3. Explosively clad bimetal sheets for use in atomic industry Chernobai Yu.P, Agaurov S.Yu,,Bochkarev A.A., and Nikolaenko P.A. Metal Market Co.Ltd, Moscow,109428, Russia Technological bases of industrial technology • Choice of the scheme of welding taking into account properties of welded materials, features of deformation of narrow sides and scraps of an overhang of a plating sheet; • Rational technology of preparation of surfaces of initial materials and assembly of packages; • Use as explosive substances (ES) of mix of microporous ammonium nitrate with diesel fuel; • Minimizing of influence of external factors due to performance of all operations on preparation for welding by explosion in shop and only an apportion of a charge of ES and its blasting on an explosive platform • Quality control at all stages of production of bimetal; Influence of a tamping and way of preparation of the low-speed ammoniac nitre the explosives substances (ES) on detonation properties Speed of detonation for ammonium microporous nitrate with content diesel fuel of 4% 3000 2800 Speed of detonation, м/с 2600 2400 2200 2000 1800 1600 1400 1200 1000 0 10 20 30 40 Ручное смешивание, без забойки Ручное смешивание, с забойкой Механическое смешивание, с забойкой 50 60 70 80 Charge height, мм 90 Decrease in ecological threat by production of large-size bimetal 31(26+5)×2100×13100 мм Protection against an air shock wave air and mechanical foam Production of bimetal in Krasnoarmeysk the Moscow Region. Preparation of packages in shop On an explosive platform Ready bimetal after heat treatment and editing The production technology of large-size pipe lattices steel-titanium for nuclear mechanical engineering and its introduction. Bimetal steel+titanium after editing Pipe lattice of the condenser The condenser of a desuperheater for the block of nuclear power plant BIMETAL for METALLURGICAL and CHEMICAL MECHANICAL ENGINEERING Preparations of pipe lattices brand 09G2S+L63 steel-brass Two-layer sheets brand 09G2S+M1 steel-copper Main leaf from 30 to 200 mm thick Plating layer from 8 to 12 mm thick Adapters steel-copper, steelaluminum Bimetallic токоподводы the titan copper for BT1-0+M1 brand electrolyzers the mm Ø24x1200 size. High corrosion resistance, decrease in electrolosses Plugs composite Resistance of ceramic 15 kOhm. The deviation of uniformity of sinking on all length made +/-0,3 mm. Durability on compression of a ceramic layer of 65 MPa. The combined technology explosive welding+hot package rolling Industrial production of bimetals by explosive welding in Krasnoarmeysk provides to the Moscow Region • the high quality confirmed with the certificate, at competitive price; • production all-the-year-round; • short time of performance of work from obtaining the order before delivery; • providing on request of the customer of a full cycle of production, including heat treatment, finishing and carrying out tests for compliance to requirements of standards and specifications. Production joint LLC Bitrub International and scientific research institute "Geodeziya" FKP THANK YOU FOR YOUR ATTENTION!