here - Snail Aid

advertisement

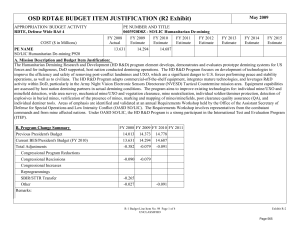

Humanitarian demining today 2008 2009 Dramatic change: 2003 – IMAS 09.10 – Clearance Requirements Wide spread food crisis Removal or destruction of all mines First Ottawa treaty deadline for completing clearance 2009 - IMAS 08.20 – Land Release Acceptance of persistency of residual risk after clearance Land release Introduction of a combination of quicker, cheaper and inherently less reliable methods to lower risk to a tolerable level Aim: using full clearance (manual + dogs + traditional demining machines) exclusively where landmines are: only 3% of cleared land is contaminated and releasing the remaining 97% by gathering and managing information through: General survey (non-technical not physically entering the SHA) Technical survey (technical using clearance assets, also POOR tools) Machines on HD tech market Heavily armoured, highly powered and high cost equipment - Like military equipment market 400.000 € 800.000$ 1.5250.000€ million$ -Strict requirements: Performance test (CEN WA: 15044): 450 landmines in 3 lanes Limited production only 650 machines operating worldwide Complex systems addressing the biggest variety of scenarios Maintenance often not possible in developing countries Should these machines be used for technical survey ? Too strict requirements? Too few machines? Reasonable use only where high concentration of mines exist Need of less expensive, more widely available, more appropriate and sustainable machines The idea Agricultural machines for technical survey Agricultural machines are originally conceived for ground processing Largely available and easily repairable (where not diffuse, an increment in number might be desirable) Can be reconverted to original use after clearance Mature and modular Help re-localization Local re-design can favour human development, empowering end-users Local re-design helping human development Human development: provide basic human needs, develop human capabilities, space to apply assets Technology: τέχνη, art or craft, and λόγος, word Agricultural machines for technical survey Requirements: • Process ground at constant depth • Withstand at least one explosion without being severely damaged • Keep operator safe Possible solutions – research fields: Ground processing tools to be attached to STD linkages or animals for machine safety: Light modular armouring plus blast resistant wheels for operator safety: External remote control or Shock isolator (driving wheel/handler, seat) Agricultural machines for technical survey For example: LOCOSTRA Co-funded by: Partners and collaborators: University of Genova, Italy Norwegian People’s Aid – Jordan LOCOSTRA, the 50.000€ machine, a tractor-based, intrusive, remotely operated, light, versatile, VERIFICATION ASSET for TECHNICAL SURVEY that can be used for AGRICULTURE when demining is over LOCOSTRA tractor 4 wheels mini tractor: Engine: 77hp, diesel Weight: 1850 kg 4WD Reversible Brakes: 4 disc brakes Steering: hydraulic, double Hitch system: 3 point, lift capacity: 1800kg LOCOSTRA remote control and armouring External remote control: control distance >100m dual: not interfering with on board control essential: forward/backward motion speed central and frontal steering 3 point linkage system differential gear blockage p.t.o brakes and emergency stop simple HMI Armouring (only for AP mines, 250g of TNT): deflection plates of 3mm thick mild steel kevlar/aramid coverings for hydraulic hoses kevlar/aramid curtain 2 electro-hydraulic valves 6 hydraulic valves 1 relay 1 switch LOCOSTRA blast resistant wheels Blast resistant and shock absorbing wheels reducing acceleration on wheel axis 2-5 times wrt a steel wheel LOCOSTRA + ground processing tool LOCOSTRA + mulcher LOCOSTRA + metal detector In-field tests in Jordan Only possible to the very important collaboration of: University of Jordan National Committee for Demining and Rehabilitation (NCDR) Norwegian People’s Aid Jordan Norwegian People’s Aid – Jordan Geneva International Centre for Humanitarian Demining In-field tests in Jordan LOCOSTRA + ground processing tool (NARDI) working at the border with Syria In-field tests in Jordan LOCOSTRA + mulcher (FAE) working at the border with Israel In-field tests in Jordan explosions under LOCOSTRA 240g of TNT 100g of TNT Main results LOCOSTRA has proven to be: Blast resistant up to 280g of TNT: working well after 7 explosions Easy to deploy (double set of wheels, crane, trailer,..) Appropriate and sustainable technology (spare parts found on the local market) Easy to use (driven succesfully by Frank right after having received the remote control transmitter in his hands) Versatile (succesfully employed with potato digger - never used before - and with mulcher) Main results Some agricultural activities that could benefit by LOCOSTRA tractor: (picture taken neear by the test areas /minefields) Main results – Sibenik symposium 2011 Main results – Sibenik symposium 2011 The pink tractor small revolution LOCOSTRA Vs another machine for demining (original size) Contacts emanuela elisa cepolina patfordemining@gmail.com gianni polentes info@pierretra.com matteo zoppi zoppi@dimec.unige.it