Energy Efficiency in Industry - Energy Efficiency Management Office

advertisement

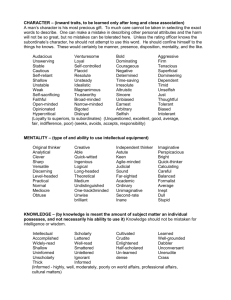

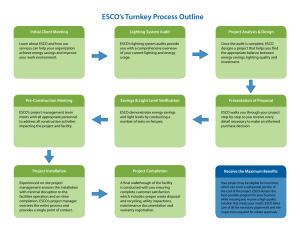

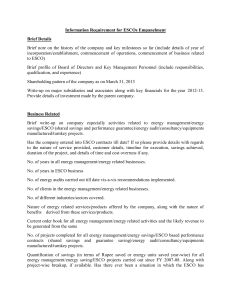

Energy Efficiency in Industry Show me the Money By Fabiani Appavou fabiani.appavou@gmail.com Why is Energy Efficiency an Issue? Energy Efficiency (EE) - Utilisation of energy in the most cost effective way to carry out an activity or a process whereby waste energy is minimised and overall consumption of primary energy resources reduced In essence, same or more with less energy Drivers of Energy Efficiency: • Rising energy prices • Energy Security • Climate Change • Green Jobs Why is Energy Efficiency an Issue? Source: BP Statistics Why is Energy Efficiency an Issue? Source: BP Statistics Why is Energy Efficiency an Issue? Benefits of Energy Efficiency Why is Energy Efficiency an Issue? Benefits to industries: • Energy savings leads to lower costs and thus increased competitiveness • Reduce environmental impacts => powerful marketing tool for green industries However !!!!! Barriers to EE implementation: • Lack of awareness and perceived risks • Conflict of investment priorities • Lack of Benchmarking ( Best Practices) • Absence of Technologies • Regulating pressure The Myths….. 1. Energy Efficiency is all about ineffectiveness, reduced productivity and reduced comfort 2. Too costly especially in during an economic downturn 3. Savings do not outweigh the cost and the risks are quite significant Consider a company with an energy bill of Rs 60 million/year With EE measure bringing a 10% energy reductions, the costs will decrease by Rs 6million. If we are to increase the sales by the same amount, lots of effort in advertising, product design would be needed with much uncertainty… The Myths….. Some facts: • Savings are for real….. IBM saved $43 million in 2011 due to EE measures ; $400 million since 1990. IBM is currently the US Greenest company. In June 2012, company’s profit rose by 6% despite fall in revenues. • Huge Energy savings Potential Recent study shows that savings up to Rs 1,110 million is possible in Mauritius Some 200 GWh of electricty can be saved Energy savings potential up to 20% achievable in some sectors. The Myths….. IRR of EE Projects over a period of 5 years Source: UNIDO The Usual Suspects Main systems that consume energy in Industry: • HVAC systems • Compressed air system • Heating and cooling processes • Electrical system • Lighting • Motors • Boilers • Refrigeration • Drying • Waste Treatment Approaches to Energy Efficiency • Passive Energy Efficiency The use of material or devices that use less energy to perform the same function. E.g. Lighting, high energy efficient motors… It is termed passive as once implemented it will save energy without any human involvement Energy savings : 10 – 15 % Approaches to Energy Efficiency The Rebound Effect Approaches to Energy Efficiency Approaches to Energy Efficiency • Active Energy Efficiency Intelligent use of energy to achieve the same result with less E.g. Automation and Regulation to ensure optimal functioning of processes Energy savings: 5 – 15 % Both approaches are needed and complement each other - Active Energy Efficiency is needed so as to maximise and sustain the savings obtained from Passive EE actions - Starting point is however Employee Awareness and Behavioural change - Approaches to Energy Efficiency Energy Efficiency is not a ONE TIME PROJECT. It is a CONTINUOUS CYCLE…… And this is a good thing!!!!! WHY ? A Continuous Cycle Monitor Evaluate Identify Realise A Continuous Cycle • • - Identify Perform an Energy Audit of the different processes Understand the energy flows Identify the low hanging fruits such as leaks, insulation needs, lighting Evaluate Understand the energy savings potential and the cost involved Allow proper planning of investments and priorities • Realise - Usually, the low hanging fruits are addressed first - Some actions don’t even involve any costs and can be implemented immediately • Monitor - Monitoring is needed to ensure that the measures are effective - Use of management and control systems - Energy savings : 2- 8 % Energy Benchmarking A New Design Mentality Nine Dot Problem How do you connect all 9 dots arranged in a square with only 4 straight lines? A New Design Mentality A New Design Mentality A New Design Mentality Geographer’s Solution A New Design Mentality Origami Solution A New Design Mentality Redesigning an industrial power loop can reduce power use by up to 92% 1. Use Bigger Pipes and smaller pumps 2. Lay the pipes first then the equipments Source: Amory Lovins, RMIT Financing EE improvements: ESCO ESCO: Energy Service Companies - An ESCO allows a client to upgrade its facilities and reduce energy costs by investing future cash flows from energy savings - ESCO’s are not financial institutions - They perform energy audits, design and install the proper technology to reduce energy use and provide a guaranteed level of savings - ESCO’s get reimbursed together with a profit with energy savings made Bernard Jamet, UNEP EE & RE Synergies • Twin Pillars of Sustainable energy: the more efficiently energy services are delivered, the faster renewable energy can be deployed • RE technologies are mostly suited for distributed purposes thereby reducing lost in transmission and transport • Efficient Building designs that utilise passive solar heat and light reduce their energy consumption • Savings from EE improvements can be used to finance RE sources such as PV • The more you reduce the energy demand of an industry, the easier it is to deploy renewable energy within that industry premises GSR 2012, REN21 Concluding Remarks • The tourism industry is embracing EE measures - Long Beach hotel has implemented EE equipments but also a building management system • Similar measures are being taken in the textile industry - Denim Ltd have purchased new weaving machine and is implementing various energy efficient practices . - RT Knits has realised a drop of 30% in fuel consumption - Tamak has already achieved a 20% savings on electricty costs and is currently undergoing an energy audits Concluding Remarks Thank you for your attention Questions & Comments