Chapter 18 - Ivy Tech -

advertisement

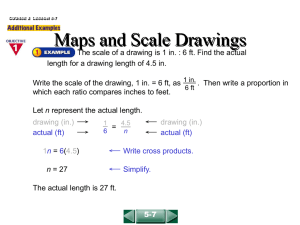

Chapter 18 Working Drawings Objectives • Specify the contents, formatting, and organization of engineering drawings • Correctly prepare and interpret formal, professional engineering drawings Objectives (cont’d.) • Discuss the primary differences between drawings used in manufacturing projects and those used in construction projects • Effectively use scales to measure the length of lines on a drawing Introduction • Manufacturing vs. construction drawings • For fabrication or construction, drawings must be presented in formal and professional manner – Must be interpreted in same way by everyone – Engineering drawings considered legal documents – Reflect on quality of originator Making It Formal • Working drawings – Show each part in all views necessary to define features, sizes, tolerances, and assembly method – Have prescribed presentation form – Should be organized, neat, and polished Making It Formal (cont’d.) FIGURE 18.03. The typical progression of the design of a part from a conceptual hand sketch to a computer 3-D model to a formal working drawing extracted from the model. Sheet Sizes FIGURE 18.04. Some relative standard sheet sizes, international and US, used for formal drawings. The Formal Drawing Header in Manufacturing Drawings FIGURE 18.07. A typical header for a formal engineering drawing. The Formal Drawing Header in Manufacturing Drawings (cont’d.) FIGURE 18.08. Inside the main title block, the definitions of the units, scale, and projection angle help the reader to correctly interpret the placement and orientation of the views and the dimensions that are shown on them. FIGURE 18.09. The name of the company, a statement of ownership of the drawing contents, and conditions of use are permanently printed in the title block. The Formal Drawing Header in Manufacturing Drawings (cont’d.) FIGURE 18.11. Signatures and dates help establish the history of development and leave a trail of accountability. The Drawing Area for Manufactured Parts • Geometry presentation – Area showing object’s geometry should be uncluttered – Complicated objects require larger sheets or multiple sheets Object Views • Use rule of orthogonal projection and multiview representation • Show as many visible edges in their true length as possible • General rule for presenting object – Start with preferred configuration – Add or subtract whatever views are necessary to best show all of the geometry Notes • Special processing, handling, or assembly procedures that are required but cannot be specified by dimensions and tolerances or by materials specifications • Usually numbered and listed together • Generally added whenever you want something done to a part and you do not know how else to specify it Parts, Subassemblies, and Assemblies FIGURE 18.18. A set of drawings for a project is organized like the roots of a tree. Individual parts fit into subassemblies or the main assembly. Subassemblies fit into higher subassemblies or the main assembly. Exploded Assembly Drawings FIGURE 18.20. An exploded assembly drawing including a bill of materials for a machine vise. Outline Assembly Drawings FIGURE 18.21. An outline assembly drawing of the machine vise. Sectioned Assembly Drawings FIGURE 18.22. A sectioned assembly drawing of the machine vise. The Bill of Materials • Text list of parts, subassemblies, and subassembly parts – Item number, corresponding part number, part name, material from which part is made, and number of times part is used in assembly • Can appear on any assembly drawing or as separate drawing or document – Usually printed as a table on an assembly drawing Manufacturing Detail Drawings FIGURE 18.23. Detail drawings for the machine vise. Manufacturing Detail Drawings (cont’d.) FIGURE 18.23. Detail drawings for the machine vise. (continued) Manufacturing Detail Drawings (cont’d.) FIGURE 18.23. Detail drawings for the machine vise. (continued) Manufacturing Detail Drawings (cont’d.) FIGURE 18.23. Detail drawings for the machine vise. (continued) More Examples of Manufacturing Drawings FIGURE 18.27. Working drawings for the computer disk drive spindle. More Examples of Manufacturing Drawings (cont’d.) FIGURE 18.27. Working drawings for the computer disk drive spindle. (continued) More Examples of Manufacturing Drawings (cont’d.) FIGURE 18.27. Working drawings for the computer disk drive spindle. (continued) More Examples of Manufacturing Drawings (cont’d.) FIGURE 18.27. Working drawings for the computer disk drive spindle. (continued) More Examples of Manufacturing Drawings (cont’d.) FIGURE 18.27. Working drawings for the computer disk drive spindle. (continued) More Examples of Manufacturing Drawings (cont’d.) FIGURE 18.27. Working drawings for the computer disk drive spindle. (continued) Construction Drawings • Why construction drawings are different from manufacturing drawings – Construction projects • • • • Typically site-specific and large-scale Often use the English system of units Do not often use 3-D modeling Are always built from the ground up How Construction Drawings Are Different from Manufacturing Drawings • Profile views vs. plan views vs. elevation views • Documentation – Set of construction plans – Specifications (specs) How Construction Drawings Are Different from Manufacturing Drawings (cont’d.) • • • • Bearings Control points Benchmarks Site survey – Existing features or structures How Construction Drawings Are Different from Manufacturing Drawings (cont’d.) • Construction projects too large and expensive to build prototypes – However, small-scale models sometimes used • Unforeseeable problems likely – Changes tracked on as-built drawings Construction Plans • Large number of drawings – Cover sheet, site plan, elevation views, foundation plan, floor plans, electrical plans, roofing plans, sections, detail drawings, etc. • Schedules of materials • PE is legally responsible Cover Sheet FIGURE 18.32. Cover sheet and index for the Baraga water treatment plant expansion project. Site Plan FIGURE 18.33. Site plan for Baraga water treatment facility showing existing structure as well as nearby highway. Elevation Views FIGURE 18.34. Elevation view for overflow and drain portion of lagoon. Foundation and Floor Plans FIGURE 18.36. First floor plan for the Baraga water treatment facility. Sections FIGURE 18.38. General section through a house showing room layouts. Detail Construction Drawings FIGURE 18.41. Detail drawings showing how a door will be installed in the Baraga water treatment facility. Plan and Profile Drawings FIGURE 18.42. Plan and profile drawing showing the street and corresponding sewage pipe for wastewater system in Baraga. Engineering Scales • Virtually all engineering drawings made to scale • Ratios – 2:1 means two inches on paper equals one inch on object • Scale indicates how close you are to object Engineer’s Scale FIGURE 18.45. Line to be measured at a scale of 1"=200' and a 20 Engineer’s scale. FIGURE 18.46. Lines drawn at a scale of 1"=40' and a 40 Engineer’s scale. Metric Scale FIGURE 18.47. Line drawn at a scale of 1:2000 and a 1:20 Metric scale. FIGURE 18.48. Lines drawn at 1:1 scale and a 1:100 Metric scale. Architect’s Scale FIGURE 18.49. Line drawn at a scale of 1⁄4"=1'-0" and a 1⁄4" Architect’s scale. FIGURE 18.50. Line drawn at a scale of 1⁄8"=1'-0" and a 1⁄8" Architect’s scale. Considerations for 3-D Modeling • Easy to generate: – Different views – Dimensions – Headers • Software cannot fully interpret functional requirements – E.g., acceptable dimension tolerances Summary • Learned that drawings must be able to communicate desires of engineer or designer • Discussed formal drawing format with proper views, sheet sizes, headers, and drawing organization • Discussed different types of scales and their physical meaning