The MTC journey - Manufacturing Research Platform

advertisement

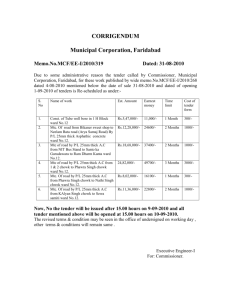

Advanced Manufacturing Lessons Learned from the UK The MTC journey (in 20 months…) March 2010 Nov 2010 Aug 2011 Nov 2011 The MTC journey March 2010 The MTC journey Nov 2010 The MTC journey Aug 2011 The MTC journey Nov 2011 UK Manufacturing Still one of the largest manufacturers in the world Approximately half of each Airbus is made in the UK Rejuvenated automotive industry Home to 70% of Formula One teams Preferred location for food manufacture & export World class research and academic institutes 2/10/2012 © 2012 7 The UK Value Proposition The UK has a world class academic base …..but UK plc. has failed to capitalise on the early stage research coming out of Universities 2/10/2012 © 2012 8 The MTC Partnership Solution The Completed Capability Pipeline Research Partners 1 Basic Idea 2 Concept Developed 3 Proof of Concept Industrial Members MTC 4 Process Validation In Lab 5 Process Validation Production Scale 6 7 8 9 Process Capability Validated Capability Validated Economic Run Capability Validated Range Of Parts Capability Validated Over Long Period The Complementary Funding Pipeline Business EPSRC TSB 2/10/2012 © 2012 9 Manufacturing Technology Centre Purpose: To improve the business performance of our members by providing novel and well developed manufacturing solutions Founded by leading research organisations: University of Birmingham Loughborough University University of Nottingham TWI 12,000m2 facility set up with £40 million of public investment 2/10/2012 © 2012 10 Research Themes Originally FOUR core research activities: Intelligent Automation High Integrity Fabrication Advanced Tooling & Fixturing Net Shape Manufacturing 2/10/2012 © 2012 11 Research Themes 2/10/2012 © 2012 12 Net shape manufacturing Additive Manufacturing (AM) Net Shape Hot Isostatic Pressing (HIP) Diffusion bonding Non-Destructive Evaluation (NDE) 3D measurement – internal & external Research partner: University of Birmingham Active projects: Rail wheel cladding & Medical implants 2/10/2012 © 2012 13 High integrity fabrication Rotary Friction Welding Automated Joining Processes High Accuracy Arc Welding Laser Processing Joint Analysis and Testing Research partner: TWI Active projects: Automated welding of aerospace components 2/10/2012 © 2012 14 Intelligent automation Elimination of manufacturing induced defects Automated in-line inspection High variety, low volume, very complex products Human-robot cooperation Process control & monitoring Research partner: Loughborough University Active projects: Automated turbine blade manufacture & Sticky food handling 2/10/2012 © 2012 15 Advanced tooling & fixturing “Right-First-and-Every-Time” rapid product setup Reduced jigs and fixtures inventory Metrology-assisted control of process error build-up and propagation Mechanical or electronic in-process adaptive control of clamping forces to improve product and process stability Research partner: University of Nottingham Active projects: Multi spindle drill head & Automated sealant application 2/10/2012 © 2012 16 Electronics manufacturing Elimination of manufacturing induced defects and adverse reliability impacts Solder-free packaging/assembly Development of higher temperature tolerant materials and interconnects Development of new materials and manufacturing processes Research partner: Loughborough University Active projects: EV-Lite & Intellico 2/10/2012 © 2012 17 Manufacturing Simulation Process simulation simulation of static & dynamic scenarios Cell simulation cell design/layout, cell operation optimisation Production line simulation assembly simulation, factory layout optimisation Overall operation of facility cost modelling, supply chain configuration/design/risk Research partner: University of Birmingham Active projects: Low drag aircraft wing simulation 2/10/2012 © 2012 18 Current Membership Tier 1 Tier 2 Tier 3 2/10/2012 © 2012 19 MTC Membership: Industry split 2/10/2012 © 2012 20 Rate of Growth New members 3 15 >30 New employees 7 45 >70 New projects 5 >30 >60 Apr ‘11 Nov ‘11 2/10/2012 © 2012 May ‘12 21 What can MTC do for you? KNOWLEDGE Sharing knowledge, info, best practice Access to experts Access to nonconfidential research RESEARCH First access to TRL13 research Significant gearing Engage in OEM & Tier 1 supply chains FACILITIES State-of-the art equipment: Production Inspection Test SERVICES X-thematic R&D Consultancy Tech transfer External research funding Advice Training 2/10/2012 © 2012 22 NETWORKING Cross sector Supply chain TIC KTN’s Showcase technology Conferences/ seminars HVM Catapult In March 2011 the UK Government announced the formation of a number of Technology Innovation Centres (TICs) – now known as “Catapult” The HVM Catapult is the country's first technology and innovation centre and will act as the model for others to follow Intended to provide an integrated capability and embrace all forms of manufacture using metals and composites, in addition to process manufacturing technologies and bio-processing 2/10/2012 © 2012 23 HVM Catapult Centres AFRC CPI NAMRC MTC AMRC WMG NCC 2/10/2012 © 2012 24 Ansty Business Park 2/10/2012 © 2012 25 Manufacturing Technology Academy 26 Contact Details Steve Statham Business Development Manager Email: steve.statham@the-mtc.org Tel: 07791 458532 Inspiring Great British Manufacturing 2/10/2012 © 2012 27