Virtual System Integration and Early Functional Validation in the

advertisement

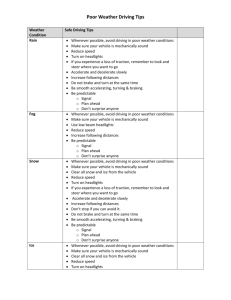

Virtual System Integration and Early Functional Validation in the Whole Vehicle Gerhard Steininger, Dassault Systèmes 1 Agenda 1. How to control system complexity? 2. System Engineering Approach – Have we done the right things? 3. Virtual Integration in the whole vehicle 4. Emergency Brake Assistance as the Use Cases 5. Conclusion and Outlook Why do we need automotive safety control systems? 3 And why do we need Advanced Driver Assistance Systems (ADAS)? 4 Control systems and embedded systems are core technologies to improve automotive safety and comfort Electronic Stability Control (ESC) Lane Keeping Assistance System (LKAS) 5 Example ADAS: Permanently increasing complexity Source: BMW Adaptive Cruise Control Front Collision Warning Lane Departure Warning Lane Keeping Assistance Lane Change Warning Parking Assistance Light Assistance System Night Vision Pedestrian Detection Up to semi and highly automated driving 6 Google self-driving car activities 7 Regulation pushes requirements Normal Driving Hazard Pre-Crash ACTIVE SAFETY In-Crash Post-Crash PASSIVE SAFETY Historically almost no regulatory enforcement Stronger consideration by ECE, FMVSS e.g.: US: Passive Safety Systems are very strongly promoted (ECE, FMVSS) - Electronic Stability Control (ESC) mandatory from 2010 Historically there are 3 focus areas: Europe: - ESC from 2011, Brake Assist from 2011 for cars - ESC incl. roll over prevention from 2011 for trucks and trailers - Emergency brake for trucks from 2014 - Lane departure warning for trucks from 2016 - ABS for Motorcycles >125 cc from 2016 ECE: Economic Commission for Europe FMVSS: Federal Motor Vehicle Safety Standards 1. Body Structure and vehicle design - Vehicle structure - Vehicle interiors - Pedestrian protection 2. Seatbelts 3. Airbags 8 Different targets Ergonomics Weight Quality Drivability Integrated Functions Environment / Emission Cost of Ownership Ride Comfort Styling Handling Safety 3DX Forum Korea 26 November 2013 9 Current state Approximately Early evaluation and validation 60% of development time no real prototype available Less Validate global vehicle 10% than of the engineers get evaluation experience in global vehicle 3DX Forum Korea 26 November 2013 10 Managing the validation effort Validation and Testing Effort Variants Technology Processes Integration Effort Network Functions Tools Methods Time 11 Merging validation and verification: X-in-the-Loop Verification Have we done things correctly? Tested on system level and below Tested versus specifications Validation Have we done the correct things? Tested on top level Tested versus expectations and design goals X-in-the-loop approach Early integration of components, systems and algorithms into a virtual vehicle prototype Seamless evaluation and validation by virtual test driving with corporate maneuver catalogs and evaluation criteria 12 Seamless integration throughout the development process Seamless integration using CarMaker Office / MiL Office / SiL Lab / HiL Real Vehicle Models & Parameters Test Maneuvers & Evaluation Criteria 13 Virtual test driving using an integration and test platform CarMaker Functional Mock-Up Interface for Co-Simulation Engine with controls Drivetrain with controls Chassis with controls ADAS with controls E/E 14 Maneuver-based testing by virtual test driving Verification of safety requirements Validation of key functions in connected systems ACC / CAS LDW / LKAS Autonomous Driving Parking Assistance AFLS Active/Passive Safety 15 Use case: Emergency Brake Assistance (EBA) DS car model Modeled in CATIA Requirements Geometry ECU MATLAB / Simulink model for Emergency Braking FMU in Autosar Builder generated Modeled in CCode Radar / Ultrasonic / Lidar / Camera 1 – 3 independent beams with 10 – 15 m Behind windscreen or at the front For obstacle identification DA Sensor Brake FMU integrated in V6 Dymola model from Modelon / Modellica Chassis library 16 The EBA has 2 - 3 Functionalities 1 Emergency Brake Assistance PreFill Brake Assist Support Preconditioning of the Brake System Sensitivity Adjustment of Brake Assist Thresholds 2 Autonomous Braking 3 Graded, Autonomous Deceleration Request Vehicle Driver Information Headup Display Kombi HMI ADAS ACC Emergency Break Assist Pre-fill Brake Assist Support Autonomous Braking Chassis Braking Systems ABS ESC Steering Suspension 17 Required behavior models for the Emergency Brake Assist Brake Behavior Vehicle Response Autonomous Braking Sensor Behavior Environment Model Warning & Brake Pre-Fill • Adaptive Cruise Control • Lane Keeping Support Hazard Identification Speed HMI Behavior Control Behavior Therefore functional Mock-up of the whole vehicle is needed. Vehicle Behavior TTC – Time to Collision Time 18 Virtualization of the development process Engineering Processes Early validation of systems and components along the V-cycle 6. Integration and Verification 6 5. Preparation of different components specification Documents and delivery of models from suppliers 5 1. Clarification of requirements 4 4. Addition of concept properties / functional structure 1 3 3. Addition of internal requirements 2 Virtual ECU 2. Definition of fundamental concept properties Model Software Hardware Vehicle -in-the-Loop 19 From Requirements to Systems and Simulation with Verification and Validation 20 Integrating of virtual test driving into the development process • Design models • Component models • Controller models • Test catalogs • Evaluation criteria 7 6 5 Maneuvers&& criteria Criteria in Maneuvers inCarMaker CarMaker Test Conduction 4 1 3 2 • Simulation results • Evaluation results • Test reports Performance Tests • Controller Robustness • Collision Functionavoidance Tests • Braking • AEBS distance … • ACC Safety Software Tests • ESP… • ISO 26262 • Communication • Diagnostics … 21 Systems engineering based on GAAG* recommendations Remarks The figure represents the GAAG MBSE Working Group summary about the future System Engineering process 6 checkpoints along the VModel to verify the deliverables and context The process includes all R-FL-P relevant artefacts *: GAAG: Global Automotive Advisory Group 22 Major steps according the GAAG MBSE masterplan 2 Definition of fundamental concept properties Clarification of requirements 4 3 5 Addition of concept properties / functional structures Addition of internal requirements 6 Preparation of different component specs Integration and verification Test and Integration Platform MATLAB SIMULINK DYMOLA FMI 1 others Authoring Tools 23 GAAG objectives and MBSE ** roadmap Objective: Exchange of Systems Engineering Objects interfacing suppliers (solution partners) and OEM’s Actual focus of GAAG WG model based systems engineering Functions (evtl. solved by FMI* and AutoSAR) tbd. Requirements ReqIF Logic Behavioral Models FMI* Closing gaps Structuring and linking models Geometrical part of Physic JT *: FMI: Functional Mock up Interface **: Model Based System Engineering Full SE today Integration with CAE (FEA, CFD, ..) Interoperability between domains and disciplines for EBA Product Development Comments B E EE C PT Electrical Mechanical Chassis Chassis Braking Systems EBA Pre Fill ABS Brake Assist Support SW Engineering Disciplines Body P ESC Steering Suspension Autonomous Braking - There are different PD domains like Body, Chassis EE and Powertrain - Within the domains are different engineering disciplines like mechanical, electrical and SW Engineering - Every domain and the different disciplines are using different models and methods - Objective is to integrate domains and disciplines and aggregate it from subs-system to system and vehicle level The traditional PLM platform has to become a SE platform Product structure and change management Consistent, up-to-date product data Consistent Early phase Change Management Early data Cost Conceptional alternatives Weight Parametric construction Features S W a ls P ro d u k t S y st e m A rc h it e k t u r S o ft w a re L o g istik A n fo rd e ru n g s M anagem ent In t e g r. / V a lid . G e sa m t - F z g . P ro d u k t - S t r. K o n fig .- M g m t . Independent view In t e g r. / V a lid . G e sa m t sy st e m S y st e m D e sig n V e rifik a tio n T e ilsy st e m S y st e m S p e zifik a tio n E n tw ic k lu n g Kom p. / S W V e rifik a tio n Kom p. / S W H e rst e llu n g Kom p. / S W E/E Control of Commonality From target to project controlling Modularity Configuration management Target management Integration CAD/ CATIA Integration CAD/ Construction E/E E/E E/E Embedded Software Behavior Models Functions Electrics/Electronics 3D Experience 26 MBSE is possible with organization, processes and latest Technology SystemResponsible Vehicle Architect and methods and standards System related Commitment Function responsible and roles Test Manager Component Responsible HMI- Responsible R F L P ReqIF 27 Thank you. Questions? 28