PM # 1 - ippta

advertisement

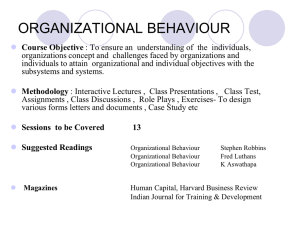

EMAMI PAPER MILLS LTD. Unit - Balasore “Efforts taken at Emami Paper Mills Ltd. for Better Maintenance Practices” LOCATION 250 KM 200 KM BAY OF BENGAL EMAMI PRODUCTION MILESTONE 900 Chart Title pm-1 800 pm-2 pm-3 bm-4 total PRODUCTION TPD 700 600 500 400 363 390 400 350 300 235 250 255 92 95 48 50 200 100 0 15 1983 20 1990 85 60 25 1996 95 65 30 2001 YEAR 110 70 40 2005 83 45 2008 2011 2014 2015 Emami –Pulp & Paper Production Units at a Glance MACHINE PRODUCT PM # 1 WRITING PRINTING PM # 2 NEWSPRINT PM # 3 NEWSPRINT RAW MATERIAL DIP # 1 PulpWriting printing DIP # 3 Pulp Newsprint WASTE PAPERS DECKLE 2.15 MTRS 2.85 MTRS 3.55 MTRS SPEED 320 MPM 515 MPM 1120 MPM Production 50-150 gsm 45 gsm 45 gsm CAPACITY 50 TPD 95 TPD 250 TPD 50 TPD 330 TPD Working Principle & Maintenance Practices Maximize the machine Uptime at optimum efficiency . Achieved target & follow up for update. Spare parts management. Critical checks & recording during any available shut. To improve the awareness of the people in the area of Best Practices in maintenance. To build a positively challenging relationship across the maintenance departments. Create a learning opportunity for the development and education of maintenance people. To create an atmosphere where people will readily share experiences and information. Use modern systems for health check of machineries. 1983 15 TPD PAPER MACHINE 1 2014 50 TPD PAPER MACHINE 1 o o o o o o Hydraulic Headbox, Fourdrinier , open draw, 2 straight Press, Pre-dryers, Size Press, Post dryer , Swimming Calender and Pope Reel ABCDEFGHIJK LMNOPQRSTU VWXYZ Approach Flow & Head box PM # 1 15 nos. @ 150 mm Plain PA Tan k HEADBOX Top Lip air vent PROBLEMS 1. Uneven parent roll built up for GSM variation 2. Failure of Micro Jack fingers due to forced Operation 18 Nos. @ 120 mm BEFORE PA Tan k AFTER air vent Pr.. Scrn Accelerating Bend JOB DONE 3. Top Lip Slot & drill for flexibility Accelerating Bend Pr Scrn F r o m P C C 2. Approach piping change to taper piping with Accelerating bend from std. piping Head box Front Panel change . No. of Micro jack increase from 15 to 18 Head box top lip redesign for more flexible T o P A t a n k 1. HEADBOX Accept to PA tank Benefit 1. Parent Roll built up improve by minimise GSM variation 2. Eliminate Micro jack failures PM # 1 Wire & Press Ø110 mm dia. & Stiff Angle Rigid doctoring system TOP FELT Plain press Roll Ø750 , 90 ° Shore A Rubber pr Ø740 , 100° Shore A Dynarock Ø750 , 90 ° Shore A Rubber 630 Ø740 ,100° Shore A Dynarock BOTTOM FELT Ø600 mm, 125 mm wide box 6/10 counter SS Couch Roll Problem : 1. 2. 3. 4. 5. Too high Draw between wire and press (23 MPM). Delayed the paper passing for Stiff angle. Paper breaks at couch lead roll for low dia. And paper drive. 2nd press Doctor passing. Steam consumption high (3.30 Mt/Ton paper for low dryness after press. 2nd pr. BOTTOM FELT Wire & Press TOP FELT 150 mm dia. lead roll VFD drive reduce stiff angle by lift up couch roll Blind drill press Rolls Ø750 BD mm, 90 ° Shore A l Ø750 , Dynaro ck Ø750 mm, 90 ° Shore A 930 Ø750 BD mm, 90 ° Shore Ø600 mm, 125 mm wide box 6/10 counter Bronze Couch Roll Work done 1. Couch roll UP by 300 mm and reduce stiff angle 2. 150 dia. Couch lead roll installed with VFD dive in place 110 mm dia. roll 3. Installed maxi flex doctor with a 2nd doctor at 2nd press top roll 4. Both 1st press top & bottom Roll changed to Blind drill Roll PM # 1 Maxiflex doctoring System & 2nd doctor BOTTOM FELT l 2nd press BOTTOM FELT Benefit 1. Reduce Draw between wire and press from 23 MPM to 12 MPM. 2. Paper passing time reduce . 3. Reduce paper breaks at lead roll. 4. Doctor passing eliminate at 2nd press roll 5. Dryness increase d to 42% from 40%. 6. Steam consumption reduce to 2.8 MT/Ton paper from 3.3 MT. 7. Deckle increase at Pope by 2 cm. 8. Speed increased to 320mpm from 300 MPM. 9. Production increase. Eliminate the Dryer felt roll breakdown PM # 1 There used to be frequent breakdown of Dryer felt rolls due to journal shearing after changing from dryer felt to screen & speeding up the machine. The journal size of 45mm was replaced with 50 mm for all felt rolls with rubber cover to avoid this breakdown Ø 160 Ø45 Chrome plated Dryer Felt Roll Ø 180 Ø50 Rubber cover Dryer Felt Roll Year Pre dryer Post dryer Total 2008 5 2 7 2010 3 2 5 2012 1 1 2 2013 0 0 0 2014 0 0 0 10 PM # 1 Size Press Problem 1. 2. 3. 4. 5. 6. 7. 8. Roll life 1 month Single line shaft drive Paper passing delay Size solution GPL 30 Size gain less Paper wrapping Pneumatic loading Nip load too low 15 kg/cm NIP load size press pm1 20 nip load kg/cm Paper 15 Nip load( Kg/cm) 10 5 Paper 0 0 Loading 1 2 3 4 5 6 air pressure kg/ cm sq Unloading NIP load size press pm1 Workdone Benefit 1. Roll Life increase from 1 month to 2 month 2. Paper passing easy Loading Unloading 25 nip load kg/cm 30° 1. Made inclined size press from horizontal 2. Made drive arrangement to lead out roll 3. Made loading 4. Size solution increase to 50 GPL 5. Nip load increase to 20 kg/cm 20 15 Nip load( Kg/cm) 10 5 0 0 1 2 3 4 5 air pressure kg/ cm sq 6 PM # 1 NIP load size press pm1 nip load kg/cm Proposed Size Press 35 30 25 20 15 10 5 0 0 10 15 20 25 30 35 40 Hyd Pressure kg/ cm sq 45° Proposed modification 1. For Further Roll Life increase and size gain we plan to installed AC VFD drive both top & bottom roll and hydraulic loading arrangement Loading Unloading CALENDER Before After PM # 1 Problem 1. Roll wear out was fast about 500 µm 2. Roll changing (Grinding) Frequency- 4 month 3. Parent roll not built up uniform. 4. Weight loss more 5. Paper smoothness not appropriate 6. Roll changing time takes more - 12 hours 7. Roll Edge wear out more for rigid doctoring system result Deckle short Work Done 1. Installed new 2 roll swimming calendar system in place 4 roll stack 2. Installed swimming roll at bottom with hyd. loading system and heating arrangement 3. Both top and bottom roll provided maxi flex doctoring system Benefit 1. Roll wear out minimum 100 µm. 2. Roll changing (Grinding) Frequency increase - 12 month 3. Control Crown, Parent roll built uniform 4. Weight loss minimum. 5. Paper smoothness improve 6. Roll changing takes 4 hours 7. No Deckle shortage as no wear at edge for maxi flex doctoring system 1996 60 TPD PAPER MACHINE 2 Hydraulic Headbox, Fourdrinier wire, Close draw, Bi-nip press, Dryer , Swimming Calendar and Pope Reel PRODUCT NEWSPRINT RAW MATERIAL RECYCLE DECKLE 2.85 MTRS SPEED 515 MPM GSM 45 PRODUCTION 95 TPD 2014 95 TPD IPPTA: promoting paper industries growth PM # 2 Vac Box bearing failures of Suction Pick up roll and Suction Couch roll Back head DS Bearing Vacuum box Bearing Assemble Problem 1. Frequent failure of locking pins & Bearing failures of box brg. assemble Workdone ----- BEFORE AFTER Back head Vacuum box Bearing Assemble DS Bearing 1. Bearing assemble arrangement changed from Vac box to Drive head 2. Bearing size change from 23220 to 22322 3. Stud shaft dia. change from 70 mm to 85 mm Benefi t Year Pick up roll Couch roll Speed, MPM Producti on loss MT 2008-09 9:25 34:50 470.1 160 2009-10 14:50 16:00 494 118 2010-11 10:00 00:00 505 39.00 2012-13 00:00 00:00 506 00.00 2013-14 00.00 00.00 515 00.00 Roll diameter increase & Maxi flex doctoring system improve press part efficiency PM # 2 BEFORE Problem Face Groo ved Ø570 SP U Centre Press Roll Ø805Ø825 Ø6 50 F D R 1. CO UC H Roll 2. 3. W as h ro ll Workdone 1. 2. 3. Groo ved Roll Ø590 SPU Centre Press Roll Ø850 Ø650 FDR AFTER Couch WA SH Ink deposition on the centre press surface increase downtime for cleaning and paper breaks Doctor blade life low 5-7 days only Narrow Nip width , Dryness of press 42% Centre press roll and Grooved roll diameter increase. Maxiflex doctoring system installed in place rigid doctoring system. Hole screen replace by 0.15 mm slotted screen Problem Face 1. 2. 3. No Ink deposition on the centre press surface increase uptime and no paper breaks 3-4 days. Doctor blade life low 15-17 days only Wide Nip width , Dryness of press increase 42% to 44.5 % PM # 2 FLEXIBLE doctoring system on Top Roll of PM # 2 Calender BEFORE AFTER Rigid Doctor Problem 1.Doctor Loading not uniform, at Edge more. 2. Wear out at edge up to 500 µm. 3. Grinding frequency 4-5 month. 4.Roll life less Maxiflex Doctor Work done 1.Replace Rigid doctoring by maxi flex doctoring system. Benefit 1. No edge wear out doctor Load uniformly distributed 2. Wear out only up to 50-75 µm. 3. Grinding frequency 8-9 month 4. Roll life increase. HEAD BOX STEP DIFFUCER BLOCK PM # 2 PROBLEM : 1. Heavy leakage due to HDPE step diffuser block crack and no spare in hand 2. Repaired temporary by isolating Horizontal Movement of Top Slice lip. 3. Flow not uniform and Channelling . Heavy leakage Headbox diffuser BLOCK CRACK PM # 2 Manufacturing Head Box Diffuser block at Home Work done BOX SS 304 1. Diffuser Block’s Drawing, Design Developed &Manufacture at home. 2. Arranged 182 nos. HDPE diffuser Nozzle by injection moulding at Kolkata. Benefit HDPE DIFFUSER 182 nos. 1. Run the machine at full speed and produced good quality paper. 2. Paper rejection and finishing loss go down. PM # 2 PM # 2 Speed UP ( in MPM) 520 510 500 500 505 510 490 477 MPM 480 470 460 460 450 440 430 YEAR 2008-09 1. 4 nos. 200 mm dia. Uhlebox in place of 150 mm with ceramic 2009-10 1. Head box lip changed 2. Fan pump impeller dia increase from 365 to 380mm 2010-11 1. Head box electro polish. 2. Pressure screenmay with 015 mm slot 3. Uhle box slot 10 mm to 13 mm 2011-12 1. 850 mm Centre press roll in place 805 mm dia 2. Centre press Maxi flex doctor ing system 3. 570 mm to 590 mm Groove 4. 0.5° Hydrofoil 2012-13 1. Orthoflow PAPER MACHINE 3 2007 205 TPD Hyd.headbox, Twinwire Gap former belbie IV Trinip Ceramic Nipco Press, Dryers, 2014 Double stack Soft Calender 250 TPD & Pope Reel IPPTA: promoting paper industries growth PM # 3 Abnormal vibrations in the forming section at wire part. Before Bow roll Forming roll HB After Bow roll Problem 1. Too much Vibration at Forming roll. 2. Restricted speed up above 1000 mpm Work done 1. FE analysis carried out By IIT , Kharagpur. 2. Bow roll reposition with new bracket Benefit 1. Vibration reduce. BEFORE VIBRATION DRIVE END BEARING 13. 10.1 3.32 MPM 985 NON DRIVE END 8.71 8.49 3.21 AFTER VIBRATION Forming roll HB 7.5 4.3 1.8 1058 3.5 2. Speed up the machine to 1120 MPM 2.3 1.53 PM # 3 Higher vibrations of Dryer Frames and paper breaks for sticky coming along with recycle pulp Problem : BEFORE: Original Dryer Frame configuration 1. Vibration in dryer frame 2. No doctoring system on dryer for sticky cleaning Work done 1. Arch type Tie connected in between dryer frame 2. Installed doctoring system on every dryer. AFTER: Dryer Frame configuration with addition of Arch Beams Benefit 1. Vibration Reduce 2. Keep the dryer surface clean. In house overhauling of swimming & nipco roll reduces foreign experts cost. PM # 3 BEFORE Previously the Swimming roll and Nipco roll servicing was carried out by sending the rolls to Europe. PRESENT We have developed in house facilities for overhauling & maintenance of same Modern maintenance practices at Emami Condition monitoring system(SPM) On-line condition monitoring system installed at Emami PM # 3. This on line system is very effective for unplanned stoppage, fire safety. The bearing changed as per online condition symptom on planned and unplanned as follows Year Planned Unplanned(downtime) 2011 33 7 2012 17 2 2013 16 0 2014 6 1 Condition monitoring on off line: Offline bearing conditions are also monitored regularly and 20% bearing consumption cost reduces since last 5 years Proactive maintenance Regularly monitoring the lubricant quality prevent downtime in Nipco roll Swimming roll and COL system rolls and cylinders bearings SCREW PRESS MOTOR DATE 06-112014 06-042014 06-032014 TORQUE DRIVE END HOR VERT LR/HR 44/35 31/25 31/25 AXIAL M IN MAX MIN MAX MIN MAX 2.19 2.21 2.3 1.92 1.3 2.21 1.25 1.31 1.16 2005 48 TPD Deinking Plant 1 2014 54TPD WE SHALL OVERCOME Power Saving in DIP 1 KW/MT F paper 600 519.6 478.33 500 456 364 359 355 2011-12 2012-13 2013-14 400 PROBLEM 1. Power consumption too high 300 200 100 0 2008-09 2009-10 PARTICULARS 2010-11 Horizontal slot screen 0.15 mm slot Horizontal Hole screen dia 1.8/2.2 Vertical slot screen 0.15mm slot Vertical hole screen dia 1.4mm Ø740 x 600 Ø500 x 430 Ø495 x 500 Ø495 x 495 % of Open area 4.2 9 5.7 12.7 Rotating element weight Kg 580 275 270 270 Rotor dia 733 496 490 490 Rotor rpm 571 763 440 715 Tip velocity m/sec 22 20 11 18 1.6 -1.8 % 2.5-2.6% 0.8-2.0% 3-3.5% BKW 75 39 15 31 Motor KW 90 45 18.5 37 Motor rpm 1500 1500 1455 1450 Motor FLC 157 81 35 66 Motor RLC 128 74 25 55 Running KW 77 44 15 33 Slot/Hole size Basket size Inlet Consistency (% ) Work Done 1. Study individual power consumption trend of equipment's in DIP plants. 2. Identified screening section consuming more power 3. Select appropriate equipment and installed 4. Power consumption reduce from 121 KW to 48 kw. BEFORE MODIFICATION in SCREENING SECTION POWER CONSUMPTIN WAS 121 KWH/MT F paper DIP # 1 Diabolo slot Mac cell Diabolo hole POWER 520 KWH/PAPER Coarse Hor. Hole screen 45 kw Constant level chest & pump Fine Hor. Slot screen 90 KW Fine screen feed chest & pump AFTER MODIFICATION in SCREENING SECTION POWER CONSUMPTIN IS 48 KWH/MT F paper Mac cell POWER 360 KWH/PAPER Diabolo slot Diabolo hole HD cleaner Constant level chest & pump Coarse Ver hole screen 37 KW Fine screen feed chest & pump Fine Ver. slot screen 18.5 KW 2007 300 TPD Deinking Plant 3 2014 330 TPD ABCDEFGHIJKL MNOPQRSTUV WXYZ Reduction of Screw press vibration in of Deinking Plant: Problem 1. Too much vibration at DS screw for polished screw surface . 2. Coupling failure. 3. Basket damaged. 4. Production hampered for frequent stoppage for roughening the polished screw surface. Work Done 1. Tungsten carbide coated body plate welded on polished screw surface Benefit 1. Eliminate excessive vibration at DS screw 2. Coupling & Basket not failed/damage since body plate installed. 3. Frequent roughening not require SCREW PRESS DRIVE END HOR VER AXIA NON DRIVE END HOR VER AXIA AFTER TORQUE 06-04-2014 06-03-2014 BEFORE 01-09-2014 26/12/2013 56% 56% 1.02 0.78 0.51 0.38 0.59 0.29 1.17 0.84 0.79 0.4 0.97 0.35 54% 55% 5.5 6.5 2.6 4.2 1.3 2.6 3.7 4.3 4.7 5.5 3.5 5.1 DIP # 3 Cost Reduction on Reject Plastics Handling in Deinking Plant: Problem Work done DIP # 3 Benefit Dirty House keeping A heavy duty Bale press installed More Man power (40 nos.) Two conveyor installed which carry Less Manpower (10 nos.) the reject plastic to bale press directly from source Higher moisture ( 60%) in plastics. Clean House keeping Less moisture (20%) in plastics SAVINGS IN PLASTICS HANDLING BY INSTALLATION OF BALE PRESS & NEW CONVEYING SYSTEM UNIT Total Total PREVI PRESE SAVINGS of PRIC Savings Sl.No. PARTICULARS Savings OUS NT Manpower E Lacs/Mo (Rs.)/Day (Rs.) nth Manpower engaged in Power 1 34 10 plant for Baling & feeding Plastics Manpower engaged in DIP#3 & 4 DIP 1 plant for 6 0 shifting Plastics to Power plant/Day 6 Total Manpower 40 10 30 200 6000 1.8 Transportation 7 1044 0.24 charge Total Savings per 9 7044 2.04 month 10 Total Savings per Annum in Lacs 24.48 Conclusion 1. Frequent breakdown of Dryer felt rolls on PM#1 was eliminated by changing the journal size from 45mm to 50 mm for all felt rolls. 2. By increasing the lead roll diameter & with VFD arrangement Paper breaks at couch roll in PM#1 reduced. 3. PM#2 machine speed increased from 470 mpm to 515 mpm by in house modifications in suction couch & suction pickup roll, adding wire table dewatering element & installing maxi flex doctoring system at centre press roll resulting increase in Production by 2000 MT/Annum. 4. Reduce power consumption at Deinking plant#1 by 165 KW/ton of finish paper after changing Horizontal screen by Vertical screen in both Hole & fine screening stage. 5. In-house plastic handling system reduces the manpower & nuisance in the Plant. 6. In house overhauling of swimming & nipco roll Eliminated supervision and experts cost Rs. 10 lacs / annum. 7. The deinking plant poire is being rebuild at our workshop which saves around 2.5 Lac/ year