Optimization

Automatic 3D Routing for

Aircraft Wire Harness Design

PhD Candidate: Zaoxu Zhu

Department: AWEP

Section: Flight Performance and Propulsion

Supervisor: G. La Rocca

Promoter: M.J.L. van Tooren

Start date: 01-12-2009

Funding: China Scholarship Council

Introduction

Nowadays, wire harnesses of aircraft are becoming more and more complex. The complexity is associated with the increase in number of on-board electrical and electronic systems which connect with each other via Electrical Wiring

Interconnection System (EWIS) consisting of a large amount of wire harnesses. An aircraft such as the A380 accommodates 530km of cables, 100,000 wires and 40,300 connectors. These harnesses have to be routed inside a narrow space, while accounting for the room reserved for cargo, passenger and equipment.

Not only the wire harness is complex, but its design process is complex as well.

The reasons of the complexity are listed below:

1. wire harness design process involves many disciplines such as electrical engineering, mechanical engineering.

2. the innovation of aircraft design raises the new problems of wire harness. For instance, Faraday cage does not exist anymore while the composites are used.

3. wire harness design process is subject to a large number of requirements, rules and regulations addressing the increasing number of constraints associated with electromagnetic interference, corrosion, abrasion, degradation, installability, maintainability and so on.

4. wire harness design is a very labor intensive process but still suffers the continuous design changes of other part of aircraft such as customization of airlines or modification of structure.

A part of wire harness systems in A380

Objective

Wire harness design consists of two parts, Electrical Design and Physical Design.

Electrical design

Physical design

Why How

This research focuses on a part of physical design, namely:

Harness 3D Routing which solves how to route the harness in aircraft.

The objective of this research includes:

1. developing a 3D harness routing system on one hand to store the knowledge of wire harness and its design process to support the automation of 3D harness routing, on the other hand to generate the harness 3D geometry model automatically for manufacture and installation.

2. developing 3D harness routing and optimization methods to achieve the automation of 3D harness routing and optimization on harness weight.

Methods

1. Knowledge Based Engineering:

Knowledge Based Engineering is a methodology which is able to automate certain steps of design process using Knowledge Based Engineering system (KBEs) to capture and store the involving process and product knowledge and to generate geometry model. The framework of the use of KBE to support 3D harness routing is called Design and Engineering Engine.

Start initialization

Requirements

MULTI MODEL GENERATOR(MMG)

Harness

Physical Model

INITIATOR

Calculating product model parameter values

& check of them on

1. compliance with requirements

No Yes

1

OPTIMIZER

Check of analysis results on:

1. convergence

2. compliance with requirements

CM for

Clamping

Distance

Analysis

CM for

Bend

Radius

Checking

CM for

Geometry

Collision

Checking

CMs for

Hazardous

Areas

Analysis

XML IGES ...

REPORT

FILES

No

1

Yes

2

Yes

No

End

CDAT- Clamping Distance Analysis Tool

HBRAT- Harness Bend Radius Analysis Tool

GCAT – Geometry Collision Analysis Tool

HRATs- Hazardous aRea Analysis Tools

Data files optimization

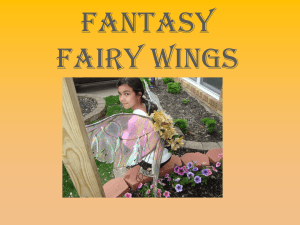

The Design and Engineering Engine (DEE) of physical design of EWIS

A. The INITIATOR is responsible for the preliminary design of wire harness while using the simplified geometry routing environment and design specifications.

B. The Multi Model Generator(MMG) is a KBE application, which is able to generate the geometry model for both analysis and design output. The geometry model generation is enabled by the High

Level Primitives (HLPs) followed by Capability Modules

(CMs), which prepare the data for the following analysis tools.

The analyses of previous defined harness are implemented by Analysis Tools. And the analysis results are sent to OPTIMIZER to support the decision making of optimization. OPTIMIZER checks the convergence of design and satisfaction of constraints according to the analysis results and generates the new value of design variables.

Optimization architecture of harness design

Progress

After years of development, part of the objective of this research has been reached.

The INITIATOR is able to generate a set of harness parameters to enable the following optimization.

The harness HLP of MMG is developed. Given the parameters generated either by INITIATOR or specified manually, it is capable of generating geometry models for following analysis or manufacture and installation.

A wire harness model generated by MMG

The optimization part of DEE is partly validated although it is not yet developed completely. The optimizer is able to generate a better solution based on the given initial values.

Original

Optimized

2. Optimization

The multi-level optimization method is applied to both the INITATOR and the rest part of DEE. The design and optimization of wire harness is decomposed into the design and optimization of each harness branch and the coordination of them.

In INITIATOR, the discrete optimization method is adopted to generate an set of feasible initial values for the following optimization.

Getting rid of the limitation of discretization, the optimization part of DEE is able to generate a less weight harness based on previous defined initial values.

Nonlinear constrained optimization method for 3D harness routing

Future Development

The rest of this research will

1. complete the development of Design and Engineering

Engine of the physical design of EWIS.

2. validate the 3D routing system using the realistic geometry models.

Publications

-Zaoxu Zhu, Michel van Tooren, G. La Rocca, (2012) “A KBE Application for Automatic Aircraft Wire Harness Routing”,

Materials Conference, DOI: 10.2514/6.2012-1843

53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and

-Zaoxu Zhu, Michel van Tooren, Stefan der Elst, (2011) “On the development of a heuristic routing application for the automatic wire harness design in the aircraft”,

AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference , DOI: 10.2514/6.2011-2148

52nd

In collaboration with Funded by