the file - Rural Community Assistance Partnership

Rural Community Assistance Partnership

Practical solutions for improving rural communities

Effectively Managing

Your Water/Wastewater

System

© 2013 All rights reserved. Rural Community Assistance Partnership, Inc. This presentation may not be used in any for-profit venture without permission from RCAP, Inc.

This training was created by

Rural

Community Assistance

Partnership

Practical solutions for improving rural communities

Western RCAP

Rural Community

Assistance Corporation

(916) 447-2854 www.rcac.org

Midwest RCAP

Midwest Assistance Program

(952) 758-4334 www.map-inc.org

Southern RCAP

Community Resource Group

(479) 443-2700 www.crg.org

Northeast RCAP

RCAP Solutions

(800) 488-1969 www.rcapsolutions.org

Great Lakes RCAP

WSOS Community

Action Commission

(800) 775-9767 www.glrcap.org

RCAP National Office

1701 K St. NW, Suite 700

Washington, DC 20006

(800) 321-7227 www.rcap.org | info@rcap.org

Southeast RCAP

Southeast Rural Community

Assistance Project

(866) 928-3731 www.southeastrcap.org

What are effective management practices?

Also known as best management practices (BMP)

Methods or techniques widely understood to be the most effective and practical means in achieving an objective (such as treating water or wastewater) while making the optimum use of the resources of a system

Doing your best with what you have

Effective management practices include:

Written operation & maintenance (O&M) manuals

– Standard operating procedures (SOPs)

Benchmarking programs

Plans for operator training, retention, and recruitment

Tools to assure financial sustainability, including asset management, viable rates, and integrated planning and budgeting

Effective management practices

Written O&M manuals

Benchmarking program

Employ trained operators

Assure financial sustainability

Two types of O&M manuals

Operational O&M manuals describe how to run the system normally and in times of emergency.

System O&M manuals describe how to run the business side of the water or wastewater system.

Operational O&M manual

System identification page

– System’s name

– Owner’s name(s)

– Address(es)

– Physical location

– Phone number(s)

– Design flow capacity

– Type of treatment

– Water source

Water system design elements

Source water

Description of type of treatment

Principal design criteria

Flow diagram

Analysis of hydraulic capacity

Pumping stations

Storage tanks

Distribution system map

Public Water System Identification Database

(PWSID) information

Wastewater system design elements

Collections system maps

Description of treatment

Principal design criteria

Flow diagrams

Hydraulic analysis

Pumping station locations

Where water is returned to the environment

Sludge removal, processing and disposal

Common to water and wastewater systems

Written standard operating procedures (SOPs)

Vulnerability assessment (VA)

Written emergency operating procedures

(EOPs) and emergency response plans (ERPs)

– personnel assignments

– chain of command

– emergency equipment inventory

– emergency phone numbers

– copies of WARNs and EMACs

Common to water and wastewater systems

Water/Wastewater Agency Response Network

(WARN) voluntary agreements are meant for systems within a state’s boundaries.

Emergency Management Assistance Compact

(EMAC) voluntary agreements are meant for systems that offer help across state boundaries.

WARN and EMAC are discussed later in this presentation.

Water system SOPs: Daily

Check water meter readings, and record water production

Inspect chemical feed pumps

Check chemical solution tanks, and record amount of chemical used

Record water level in storage tanks

Record chlorine residual at application point and in distribution system

Record turbidity (if applicable)

Inspect booster pump stations (if applicable)

Water system SOPs: Daily (cont’d)

Record fluoride concentration in distribution system (if applicable)

Record well pump running times and cycle starts (if applicable)

Check instrumentation for proper signal input and output

Investigate customer complaints

Complete a daily security check

Inspect heater operation during winter months

Inspect well pumps, motors and controls (if applicable)

Water system SOPs: Weekly

Inspect chlorine and fluoride testing equipment (if applicable)

Clean buildings and grounds and make sure fire hydrants are accessible

Record pumping rate for each well or source water pump

Conduct security check

Water system SOPs: Monthly

Read and record electric meter values

Take appropriate monthly water-quality samples

Check and record static and pumping levels of each well

(if applicable)

Read all customer meters and compare with total water produced

Inspect well heads (if applicable)

Lubricate locks

Compare on-site readings with lab results

Confirm submission of monthly reports

Laboratory information

Sampling locations, time, and methods

Collection procedures

Preservation requirements

Safety precautions

How to interpret laboratory results and use the results to improve the process

What should be in laboratory supply and chemicals inventory

Laboratory information (cont’d)

Recommended laboratory equipment, supplies, chemicals and a list of laboratory references

Instructions for completing worksheets (include examples and sample worksheets)

For tests to be performed by certified laboratories

– name of the laboratory

– contact person

– telephone number

– shipping procedures

– method of requesting sample pick-up or schedule for sample pickups

Let’s review: Operational O&M manuals

Operational O&M manuals tell how to run the

_______ normally and in _______.

True or false? Design basis of the system should be included in an operational O&M manual.

What is the difference between a WARN and an

EMAC?

Let’s review: Operational O&M manuals

Why is a written chain of command important?

Why should example sampling sheets be included in your operational O&M manual?

How does your system’s operational O&M manual compare normal operation with emergency operation?

System O&M manual

Asset-management plan

Preventive-maintenance plan

Vulnerability assessment (VA)

Emergency-response plan (ERP)

Asset-management plan

Effectively manage land, structures, equipment, software, and other assets of the system in order to use your limited finances on them wisely

Incorporates

– Expected lifetime of asset

– Planned savings for repair/replacement/upgrade

– Scheduled maintenance

– Performance measurements

EPA STEP Guide for Asset Management

Call 800/426-4791 and request EPA 816-R-03-016

Go to www.epa.gov/safewater/smallsys/ssinfo.htm

CUPSS: Check-Up Program for Small Systems

Asset-Management Tool for Small Utilities

Free, CD-based, stand-alone AM tool

For utilities serving fewer than 3,300 population

Based on successful STEP Guides

www.epa.gov/cupss

Preventive Maintenance Plan

A plan of regularly scheduled repair and replacement of equipment parts that wear out in order to avoid emergency repairs or failure of service.

Includes

– Scheduling inspections

– Detecting necessity of repair/replacement

– Performing repair/replacement

Vulnerability assessment

Discover which emergencies are most likely to affect your system

Discover which assets are the most important to providing service

Discover which assets are the most vulnerable to damage or disruption during an emergency

Vulnerability Assessment (cont’d)

Rank the annual likelihood of emergency from 1 to 10

(10 is the most likely) for RISK

Rank the damage to the equipment from 1 to 10 (10 is complete loss ) for DAMAGE

Rank the importance of equipment or treatment from 1 to

10 (10 is most important) for CRITICALITY

RISK x DAMAGE x CRITICALITY = RANKING

Highest ranking = most vulnerable

Setting priorities with a risk matrix

Vulnerability assessment (cont’d)

Once VA is completed for every piece of equipment, plan to mitigate damage from emergencies

Use ranking to prioritize which equipment is addressed first

Use ranking to budget for mitigation

Review VA annually at a minimum

Emergency-response plan

Basic elements

– Know the information about your system

– Establish roles and responsibilities

– Establish and use communications procedures

– Make sure your personnel are as safe as possible

– Identify alternative water sources

– Plan for replacement equipment and chemical supplies

– Protect your system’s property

– Perform water sampling and monitoring

Emergencyresponse plan (cont’d)

Join a WARN (Water/Wastewater Agency

Response Network) for assistance within state boundaries

Establish an EMAC (Emergency Management

Assistance Compact) for assistance across state boundaries

Evaluate the plan at least annually by using a simulated emergency on at least a tabletop scale

If there are problems with the plan, fix it and test it again

Let’s review: System O&M manual

Asset management includes recording the asset’s expected _____, planned savings for _____, preventive _____, and _____ measurements.

Why is preventive maintenance important?

Ranking the most vulnerable piece of equipment or portion of your system helps you _____ damage and _____ for budgeting.

Let’s review: System O&M manual

ERP is the abbreviation for _____.

(Any) Four of the eight elements of an ERP are

_____, _____, _____, and _____.

What is the purpose of reviewing an ERP annually?

Effective management practices

Written O&M manuals

Benchmarking program

Employ trained operator(s)

Assure financial sustainability

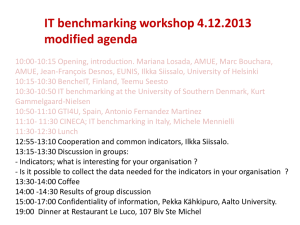

Benchmarking program

A benchmarking program is the process of determining who is the very best, who sets the standard, and what that standard is.

Benchmarking allows you to compare your system with others, to identify comparative strengths and weaknesses, and learn how to improve.

Benchmarking is a way of finding and adopting the most effective practices.

Effective management practices

Written O&M manuals

Benchmarking program

Employ trained operators

Assure financial sustainability

Employ trained operator(s)

Requirements for training and certification

Should have training for other parts of their jobs

Support your current operator(s) but have a succession plan in place

Effective management practices

Written O&M manuals

Benchmarking program

Employ trained operators

Assure financial sustainability

Major components of financial management

Budget

Budget reports and monitoring

Rate setting

Asset management

Strategic planning

Budget requirements

Annual operating expenses

Annual reserves

Annual revenue

Revenues should cover expenses

(including reserves)

Use the past to predict the future

39

Creating a budget

1.

Estimate annual operating expenses.

2.

Include setting aside reserves.

3.

Estimate revenues.

4.

Balance the budget.

More assistance for small communities

Visit the RCAP website at www.rcap.org

– Library of resources

– Links to other helpful tools and organizations

– Publications (magazine and email newsletter)

[Trainer’s name and contact info here]