Chapter 35

advertisement

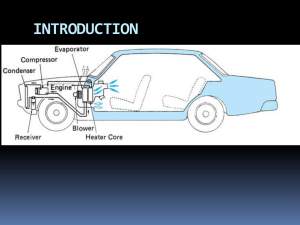

Heavy Duty Heating, Ventilation and Air Conditioning Systems Ken Collins 704-330-4183 kennth.collins@cpcc.edu Objectives • Understand the basic theory of heavy-duty truck air-conditioning systems. • Outline the requirements of the Clean Air Act that apply to a heavy-duty truck airconditioning system. • List the five major components of a heavyduty air-conditioning system and describe how each works in the operation of the system. (Objectives cont.) • Explain how the thermostatic expansion valve or orifice tube controls the flow of refrigerant to the evaporator. • Identify the refrigerants used in heavy-duty truck air-conditioning systems. • Describe the function of the main components in a typical heavy-duty airconditioning system. (Objectives cont.) • Recognize the environmental and personal safety precautions that must be observed when working on air-conditioning systems. • Identify air-conditioning testing and service equipment. • Test an air-conditioning system for refrigerant leaks. (Objectives cont.) • Outline the procedure required to service a heavy-duty air-conditioning system. • Perform some simple diagnosis of airconditioning system malfunctions. • Outline the advantages of connecting airconditioning management electronics to the chassis data bus and explain how to access the system. (Objectives cont.) • Explain how a truck cab ventilation system operates. • Describe the role a liquid-cooled heating system plays in a truck cab heating system. • Describe some types of auxiliary heating and power units. INTRODUCTION Heating, ventilation, and air-conditioning (HVAC) systems are designed to keep the cab, or cab and bunk, in a truck at a comfortable temperature. The air conditioning system also helps clean (condition) the air in the cab by removing dust, pollen, smoke, and moisture. THERMODYNAMICS To understand air-conditioning theory, it is important for the service technician to have a basic understanding of how heat behaves. The behavior of heat is a branch of physics known as thermodynamics. An airconditioning system uses some very basic thermodynamic principles to remove heat from the cab of a truck and dissipate or lose it to the atmosphere outside the truck. How air is “conditioned” in the cab. PRINCIPLES OF REFRIGERATION Air-conditioning and refrigeration systems manage basic thermodynamic principles to produce a more comfortable climate within an enclosed area. To understand how an airconditioning system works, we first have to know something about the states of matter, heat flow, and something called latent heat. STATES OF MATTER • Solid water is known as ice. • Liquid water is known as water. • Vaporized water is known as steam. The temperature of the water determines which of these three states it is in. Absolute Heat, Heat Movement, and Measurement Pressure and Heat The temperature at which a liquid boils depends on the pressure acting on the liquid. Decreasing the pressure lowers the boil point. Increasing the pressure raises the boil point. Latent Heat Whenever a substance changes state, it either releases or consumes heat energy. Latent heat is the amount of heat necessary to change a substance from one state to another. SUMMARY OF AIR CONDITIONING PRINCIPLES • Heat always moves from a warmer area to a cooler area. • When liquids are heated and evaporate to a vapor state, heat is absorbed. • When a gas condenses from a vapor to a liquid state, heat is released. Typical heavy-duty truck heating and an air-conditioning system REFRIGERANT The function of a refrigerant is to absorb heat from the air in the cab and transfer it to the atmosphere outside the cab. The refrigerants used in truck A/C systems are industrially manufactured chemicals of some complexity. Refrigerants in mobile systems are controversial and constantly undergoing change. CHLOROFLUOROCARBON REFRIGERANTS Until 1995, the common refrigerant used in a truck A/C system was known as R-12. This is classified as a chlorofluorocarbon (CFC). R-12 refrigerant boils at −22°F (−30°C, and for years, it was considered an ideal mobile vehicle A/C refrigerant. However, because it is a substance of some toxicity as well as ozone depleting, its use has in theory become strictly controlled under the guidelines of the federal Clean Air Act. HYDROCHLOROFLUOROCARBONS (HCFCS) • HCFC 134a – used in automobile and truck cab HVAC systems • HCFC 22 – used in trailer reefer systems • HCFC 40a – used in trailer reefer systems Ozone Depletion Depletion of the ozone layer has occurred at a rate of around 4 percent per decade since the mid-1970s and is beyond the scope of this textbook. A simple explanation requires understanding a little about ozone. Ozone in the upper atmosphere filters out some of the harmful sunlight directed toward Earth. Chemically, ozone (O3) is triatomic oxygen; that is, three oxygen atoms bond to form an O3 molecule. Future Refrigerants Europe currently requires trailer reefers to be equipped with electrical standby for use whenever a vehicle is parked so that CO2 is not produced while running an onboard reefer engine. To minimize refrigerant losses, flared fittings are being phased out in favor of brazed unions, reducing the incidence of leaks. Also under consideration are the use of hybrids and semi-hermetic compressors. Refrigerant Oils HCFCs require the use of two refrigerant specific oils: • Polyalkylene glycol (known as PAG) • Polyolester (known as POE or ester) REFRIGERANT CONTAMINATION R-134a systems look similar to R-12 systems. However, refrigerants should never be mixed in a system; to emphasize this fact, it has been made illegal. Guidelines issued by the Environmental Protection Agency (EPA) specify that all refrigerants must be approved under the Significant New Alternatives Policy (SNAP). Only R-134a meets current SNAP guidelines for mobile refrigerants, but a number of other mobile refrigerants are under research. Temperature/pressure relationship of refrigerant Shop Talk Refrigerant containers for R-12 and R-134a are color-coded. R-12 containers are white and R-134a containers are light blue and clearly marked. In addition, R-134a containers use ½-inch 16 acme threads, which cannot be connected to an R-12 gauge set or recovery machine. Refrigerant identifier REFRIGERANT RECOVERY The Clean Air Act, passed in 1992, has resulted in major changes in industrial, domestic, and vehicle A/C systems. AIR-CONDITIONING CERTIFICATION Three training programs in particular are recognized by the federal government: the Mobile Air Conditioning Society (MACS), the International Mobile Air Conditioning Association (IMACA), and the National Institute of Automotive Service Excellence (ASE). THE REFRIGERATION CYCLE AIR-CONDITIONING SYSTEM COMPONENTS Refrigerant Flow Cycle Piston-Type Compressors Cutaway view of a piston-type compressor Rotary Vane Compressor Cutaway view of a typical rotary vane compressor Swashplate-Type Compressors Compressor Drives CONDENSER RECEIVER/DRYER Binary Switch Trinary Switch The trinary switch is mounted on the receiver/dryer in a similar fashion to the binary switch. The trinary pressure switch performs three functions to monitor and control pressure inside the A/C system. The low- and high-range functions are the same as on the binary switch system. Pressure Relief Valve A pressure relief valve is also often located on the receiver/dryer. It provides an added high-pressure relief feature if a failure were to develop in the high pressure cut-off switch. The pressure relief valve is designed to pop off when the refrigerant pressure exceeds a preset maximum safe pressure value. Pop off pressure can often be as high as 400 psi. Fusible Plug Accumulator THERMOSTATIC EXPANSION VALVE/ ORIFICE TUBE Thermostatic Expansion Valve (TXV) Orifice Expansion Tube EVAPORATOR THERMOSTAT (EVAPORATOR FREEZE PROTECTION DEVICE) REFRIGERATION LINES, HOSES, AND COUPLERS Hose clamp shell crimp fittings will not seal the new style barrier hose. New hoses are designed to prevent refrigerant leakage. Special Crimping Tools SIGHT GLASS IN-LINE DRYER Located between the receiver/dryer and TXV or tube, an in-line dryer absorbs any moisture that gets by the receiver/dryer. It also helps to prevent TXV or tube freeze-up. MUFFLER The muffler is usually located on the discharge side of the compressor. It also may be located on the suction side. Its function is to reduce the characteristic pumping noise produced by the compressor. BLOWER MOTOR AND FAN ENGINE COOLING FAN Shop Talk Remember that just one drop of water added to refrigerant will lead to corrosion and refrigerant breakdown. Corrosive hydrochloric acid can be produced in the older R-12 system when trace drops of water are added. Also, the smallest amounts of air in the refrigerant system can start chemical reactions that result in system malfunctions. SAFETY PRECAUTIONS Refrigerant lines are under some pressure even when the system is not running. This means that they should not be disconnected until the refrigerant has been discharged to a refrigerant recovery unit. Refrigerants are safe when handled properly. CAUTION! Refrigerant should never come into contact with skin or eyes. Liquid refrigerant, when exposed to the air, quickly evaporates and will almost instantly freeze skin or eye tissue. Serious injury or blindness could result. CAUTION! Avoid working in areas where refrigerant may come into contact with an open flame or any burning material, such as a cigarette. When it contacts extreme heat, refrigerant breaks down into poisonous phosgene gas, which, if breathed, causes severe respiratory irritation. CAUTION! Under current federal Clean Air Act regulations, refrigerants must be recovered and recycled by all users to protect the environment and should never be released into the atmosphere. Under these regulations, service facilities not having the required recovery and recycling equipment and properly trained and certified personnel are not permitted to perform any refrigeration service work. Refrigerant Storage Because of its very low boiling point, refrigerant has to be stored under pressure in containers. These containers should never be exposed to temperatures higher than 125°F. Refrigerant cans should not be left in direct sunlight. PERFORMANCE TESTING AN AIR CONDITIONING SYSTEM Because there are differences in each OEM system, this is just a general set of guidelines, and the best approach to testing and troubleshooting a system is to use the OEM service manual. Cooling Check Odor Diagnosis A/C systems may produce a musty odor, usually at startup in hot weather. This type of odor is usually temporary, and, providing it disappears after a short period of operation, should not be of concern. If it persists, it can be an indication of microbial growth on the evaporator core. This requires the removal of the evaporator core and its thorough cleaning with a disinfectant. Some other odor diagnoses are shown in Table 35–1 page 23. LEAK TESTING A SYSTEM CAUTION! Never pressure or leak test R-134a service equipment or vehicle A/C systems with compressed air. Some mixtures of air and R134a have been shown to be combustible at elevated pressures. Shop Talk Because of their sensitivity, electronic-type detectors must be correctly calibrated before each use to detect the lowest permissible leak rate of the component being checked. Trace the refrigerant system in a continuous path so that no potential leaks are missed. If a leak is found, always continue to test the remainder of the system. Shop Talk (Cont.) At each area checked, the probe should be moved around the location at a rate no more than 1 to 2 inches/second and no more than 1/4 inch from the surface completely around the position. Slower and closer movement of the probe greatly improves the likelihood of finding a leak. It also helps to place the probe lower than a suspected leak because the refrigerant is heavier than air. MANIFOLD GAUGE SETS R-12 R-134a CAUTION! Never open the high-side hand valve with the system operating and a refrigerant source at the center hose connection. This will cause refrigerant to exit the A/C system under high pressure into the source container, which could cause it to burst. The only time both hand valves should be open is when evacuating the system. Shop Talk Atmospheric pressure reduces as altitude increases. The gauge pressure must be corrected using an OEM correction chart when checking system lowside pressures. Service Valves Schrader Type Shop Talk In R-12 systems, the Schrader fitting on the high pressure side is smaller than the lowpressure side, and special adapters are necessary to connect the high-side service hose into the system. The difference in fitting sizes is to prevent mixing up the high and low-pressure sides of the system when attaching he gauge set. Shop Talk The different size fittings were introduced to prevent disposable 1 lb cans of refrigerant from being connected to the high side of the system, causing them to explode. After disconnecting the gauge lines, check the valve areas to be sure that the service valves are correctly seated and that the Schrader valves are not leaking. In R-134a systems, the size as well as the type of connection is different; that is, the larger connection is used for the high side. MANIFOLD SERVICE HOST SETS Vacuum Pump Rotary Vane-Type Vacuum Pump Shop Talk A vacuum pump is unable to remove moisture in liquid state from a system. It lowers the system pressure and, therefore, the boiling point of liquid moisture. It then removes the vaporized moisture. This is why it is necessary to pull a vacuum on a system for an extended period to ensure that no moisture is left in it. Thermistor Vacuum Gauge The electronic thermistor vacuum gauge is designed to work with the vacuum pump to measure the last, most critical inch of Hg vacuum during evacuation. It constantly monitors and visually indicates the vacuum level so that a technician will know for sure when a system is entirely free of air and moisture. AIR CONDITIONING SERVICE PROCEDURES • • • • • System recovering and recycling System flushing Compressor oil level checks Evacuation System recharging CHARGING CYLINDER OR CHARGING STATION Typical Refrigerant Stations Discharge and Suction Service Valves. Recovery Hookup PURGING CHECKING COMPRESSOR OIL LEVEL EVACUATING THE SYSTEM TOP-OFF RECHARGE OF AN A/C SYSTEM Weighing a Refrigerant Canister COMMON AIR CONDITIONING PROBLEMS Performance Testing Troubleshooting Flow Chart CONVERTING AN R-12 SYSTEM TO AN R-134A SYSTEM In theory, R-12 should not be available today, meaning that every retrofit should have taken place. In reality R-12 is still readily available. This means that there are trucks running R12 systems. It also means that shops continue to the process of retrofitting systems to comply with the MACS standards. Some of the systems are being aftermarket retrofit to blend systems. AIRFLOW LIQUID-COOLED HEATING SYSTEM HEATER CORE A typical heater core is designed and constructed very much like a miniature engine cooling radiator. It features inlet and outlet tanks connected by headers to a heat exchanger core. The heater core tank, tubes, and fins can become clogged over time by rust, scale, and mineral deposits circulated by the coolant. HEATER CONTROL VALVE A heater control valve, also known as a coolant flow valve, controls the flow of coolant into the heater core from the engine. In a closed position, the valve allows no flow of hot coolant to the heater core, allowing it to remain cool. THERMOSTAT The thermostat that helps to regulate the engine coolant temperature plays a role in providing the cab with heat. A malfunctioning thermostat can cause the engine to overheat or not reach normal operating temperature, and either of these conditions will impact the cab heater performance. COMBINATION HVAC CORE Cable-Controlled Coolant Valve Control Panel and Airflow Sleeper Compartment Heater and Air Conditioner Supplementary Coolant Heater Auxiliary Power Units (APUs) ELECTRONICALLY MANAGED CLIMATE CONTROL Most heavy-duty trucks use some level of electronic controls to manage cab climate. The terms used to describe these control systems are air-conditioning protection and diagnostics system (APADS) and airconditioning protection unit (ACPU). COMPUTER-CONTROLLED A/C COMPONENTS System components include the A/C control module, which performs logic processing of the system inputs and switches the outputs. It also includes an input and output circuit. The A/C control module masters A/C operation and tracks diagnostic data. It is usually located somewhere in the engine compartment rather than in the vehicle cab. A/C Clutch Coil A/C Control Logic BLUECOOL HEAT EXCHANGER BLUECOOL OPERATION BlueCool uses a pair of aluminum coil circuits surrounded by a graphite matrix storage core contained in insulation. One coil circuit carries R-134a refrigerant gas and the other a 50/50 mixture of ethylene glycol (EG) and water. The system uses an icebox principle. The graphite matrix absorbs water in liquid both liquid and frozen states. The storage coil is chilled down to subzero temperatures while the truck is operated on the road. Summary • Heavy-duty heating and air-conditioning (A/C) systems are designed primarily to keep the cab comfortable despite the outside weather. • Liquids absorb heat when changed from a liquid state to a gas. • Gases release heat when changed from a gaseous state to a liquid. Summary (cont.) • Heat always moves from a hotter area to a cooler area. • The temperature at which a liquid changes state to a gas depends on the pressure acting on it. • Refrigerants are required to have a low boil point and to change quickly from a liquid state to a gas state and back again. Summary (cont.) • The basic refrigeration cycle consists of compression, condensation, expansion, and evaporation. • Compression heats up refrigerant gas. Condensation changes the state of the refrigerant from a gas to a liquid. Expansion reduces the pressure of the liquid refrigerant. Evaporation changes the refrigerant from a liquid state to a gas. Summary (cont.) • There are two types of refrigerant lines: suction lines and discharge lines. • A/C systems are sensitive to moisture and dirt. Clean working conditions are extremely important. • The electrical system must be checked periodically to prevent the truck A/C system from failing unexpectedly. Summary (cont.) • Some trucks use electronic climate and A/C controls. These systems can either be standalone or connected to the chassis data bus. • Current A/C system controllers are networked to the chassis data bus. This enables them to communicate with other MIDs to optimize system operation. Summary (cont.) • When the A/C controller is networked to the chassis data bus, the system is accessed by the J1939 connector. This allows the system to be read by any software that can interpret MIDs, parameter identifiers (PIDs), subsystem identifiers (SIDs) and FMIs. To perform operations other than simply read the system, proprietary software is usually required. Summary (cont.) • The A/C electronics can respond to a request off the data bus to put the A/C compressor into dropout mode. An example would be a temporary request for full power from the engine electronics, when it would be desirable to eliminate as many parasitic loads as possible. Summary (cont.) • BlueCool uses an icebox principle to cool truck bunks during engine shutdown at zero fuel consumption and with no emissions. Any Questions ?