1 g /40 ml wastewater

advertisement

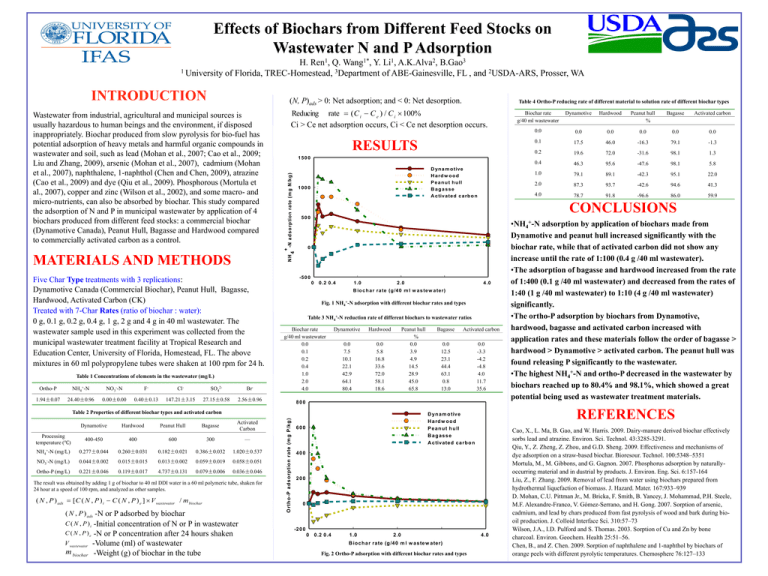

Effects of Biochars from Different Feed Stocks on Wastewater N and P Adsorption H. Ren1, Q. Wang1*, Y. Li1, A.K.Alva2, B.Gao3 1 University of Florida, TREC-Homestead, 3Department of ABE-Gainesville, FL , and 2USDA-ARS, Prosser, WA INTRODUCTION (N, P)ads > 0: Net adsorption; and < 0: Net desorption. Reducing rate ( C i C e ) / C i 100% Ci > Ce net adsorption occurs, Ci < Ce net desorption occurs. RESULTS -N a d s o rp tio n ra te (m g N /k g ) D yn a m o tiv e H a rd w o o d P e a n u t h u ll B agasse A c tiv a te d c a rb o n 1000 500 0 4 Five Char Type treatments with 3 replications: Dynamotive Canada (Commercial Biochar), Peanut Hull, Bagasse, Hardwood, Activated Carbon (CK) Treated with 7-Char Rates (ratio of biochar : water): 0 g, 0.1 g, 0.2 g, 0.4 g, 1 g, 2 g and 4 g in 40 ml wastewater. The wastewater sample used in this experiment was collected from the municipal wastewater treatment facility at Tropical Research and Education Center, University of Florida, Homestead, FL. The above mixtures in 60 ml polypropylene tubes were shaken at 100 rpm for 24 h. Table 1 Concentrations of elements in the wastewater (mg/L) Ortho-P NH4+-N NO3--N F- Cl- SO42- Br- 1.94±0.07 24.40±0.96 0.00±0.00 0.40±0.13 147.21±3.15 27.15±0.58 2.56±0.96 -5 0 0 0 0 .2 0 .4 1 .0 2 .0 Fig. 1 NH4+-N adsorption with different biochar rates and types Table 3 NH4+-N reduction rate of different biochars to wastewater ratios Biochar rate g/40 ml wastewater 0.0 0.1 0.2 0.4 1.0 2.0 4.0 Dynamotive Hardwood 0.0 7.5 10.1 22.1 42.9 64.1 80.4 0.0 5.8 16.8 33.6 72.0 58.1 18.6 Peanut hull % 0.0 3.9 4.9 14.5 28.9 45.0 65.8 Peanut Hull Bagasse Activated Carbon Processing temperature (℃) 400-450 400 600 300 — NH4+-N (mg/L) 0.277±0.044 0.260±0.031 0.182±0.021 0.386±0.032 1.020±0.537 NO3--N (mg/L) 0.044±0.002 0.015±0.015 0.013±0.002 0.059±0.019 0.058±0.051 Ortho-P (mg/L) 0.221±0.046 0.119±0.017 4.737±0.131 0.079±0.006 0.036±0.046 The result was obtained by adding 1 g of biochar to 40 ml DDI water in a 60 ml polymeric tube, shaken for 24 hour at a speed of 100 rpm, and analyzed as other samples. ( N , P ) ads [ C ( N , P ) i C ( N , P ) e ] V wastewater / m biochar ( N , P ) ads -N or P adsorbed by biochar -Initial concentration of N or P in wastewater C ( N , P ) e -N or P concentration after 24 hours shaken V wastewater -Volume (ml) of wastewater m biochar -Weight (g) of biochar in the tube C ( N , P )i Bagasse Activated carbon 0.0 12.5 23.1 44.4 63.1 0.8 13.0 0.0 -3.3 -4.2 -4.8 4.0 11.7 35.6 800 O rth o -P a d s o rp tio n ra te (m g P /k g ) Hardwood 4 .0 B io c h a r ra te (g /4 0 m l w a s te w a te r) Table 2 Properties of different biochar types and activated carbon Dynamotive Dynamotive Hardwood Peanut hull % Bagasse Activated carbon 0.0 0.0 0.0 0.0 0.0 0.0 0.1 17.5 46.0 -16.3 79.1 -1.3 0.2 19.6 72.0 -31.6 98.1 1.3 0.4 46.3 95.6 -47.6 98.1 5.8 1.0 79.1 89.1 -42.3 95.1 22.0 2.0 87.3 93.7 -42.6 94.6 41.3 4.0 78.7 91.8 -96.6 86.0 59.9 CONCLUSIONS NH MATERIALS AND METHODS Biochar rate g/40 ml wastewater 1500 + Wastewater from industrial, agricultural and municipal sources is usually hazardous to human beings and the environment, if disposed inappropriately. Biochar produced from slow pyrolysis for bio-fuel has potential adsorption of heavy metals and harmful organic compounds in wastewater and soil, such as lead (Mohan et al., 2007; Cao et al., 2009; Liu and Zhang, 2009), arsenic (Mohan et al., 2007), cadmium (Mohan et al., 2007), naphthalene, 1-naphthol (Chen and Chen, 2009), atrazine (Cao et al., 2009) and dye (Qiu et al., 2009). Phosphorous (Mortula et al., 2007), copper and zinc (Wilson et al., 2002), and some macro- and micro-nutrients, can also be absorbed by biochar. This study compared the adsorption of N and P in municipal wastewater by application of 4 biochars produced from different feed stocks: a commercial biochar (Dynamotive Canada), Peanut Hull, Bagasse and Hardwood compared to commercially activated carbon as a control. Table 4 Ortho-P reducing rate of different material to solution rate of different biochar types REFERENCES D yn a m o tive H a rd w o o d P e a n u t h u ll B agasse A c tiva te d c a rb o n 600 400 200 0 -2 0 0 0 0 .2 0 .4 1 .0 2 .0 B io c h a r ra te (g /4 0 m l w a s te w a te r) Fig. 2 Ortho-P adsorption with different biochar rates and types •NH4+-N adsorption by application of biochars made from Dynamotive and peanut hull increased significantly with the biochar rate, while that of activated carbon did not show any increase until the rate of 1:100 (0.4 g /40 ml wastewater). •The adsorption of bagasse and hardwood increased from the rate of 1:400 (0.1 g /40 ml wastewater) and decreased from the rates of 1:40 (1 g /40 ml wastewater) to 1:10 (4 g /40 ml wastewater) significantly. •The ortho-P adsorption by biochars from Dynamotive, hardwood, bagasse and activated carbon increased with application rates and these materials follow the order of bagasse > hardwood > Dynamotive > activated carbon. The peanut hull was found releasing P significantly to the wastewater. •The highest NH4+-N and ortho-P decreased in the wastewater by biochars reached up to 80.4% and 98.1%, which showed a great potential being used as wastewater treatment materials. 4 .0 Cao, X., L. Ma, B. Gao, and W. Harris. 2009. Dairy-manure derived biochar effectively sorbs lead and atrazine. Environ. Sci. Technol. 43:3285-3291. Qiu, Y., Z. Zheng, Z. Zhou, and G.D. Sheng. 2009. Effectiveness and mechanisms of dye adsorption on a straw-based biochar. Bioresour. Technol. 100:5348–5351 Mortula, M., M. Gibbons, and G. Gagnon. 2007. Phosphorus adsorption by naturallyoccurring material and in dustrial by products. J. Environ. Eng. Sci. 6:157-164 Liu, Z., F. Zhang. 2009. Removal of lead from water using biochars prepared from hydrothermal liquefaction of biomass. J. Hazard. Mater. 167:933–939 D. Mohan, C.U. Pittman Jr., M. Bricka, F. Smith, B. Yancey, J. Mohammad, P.H. Steele, M.F. Alexandre-Franco, V. Gómez-Serrano, and H. Gong. 2007. Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during biooil production. J. Colloid Interface Sci. 310:57–73 Wilson, J.A., I.D. Pulford and S. Thomas. 2003. Sorption of Cu and Zn by bone charcoal. Environ. Geochem. Health 25:51–56. Chen, B., and Z. Chen. 2009. Sorption of naphthalene and 1-naphthol by biochars of orange peels with different pyrolytic temperatures. Chemosphere 76:127–133