Hydrothermal aging

advertisement

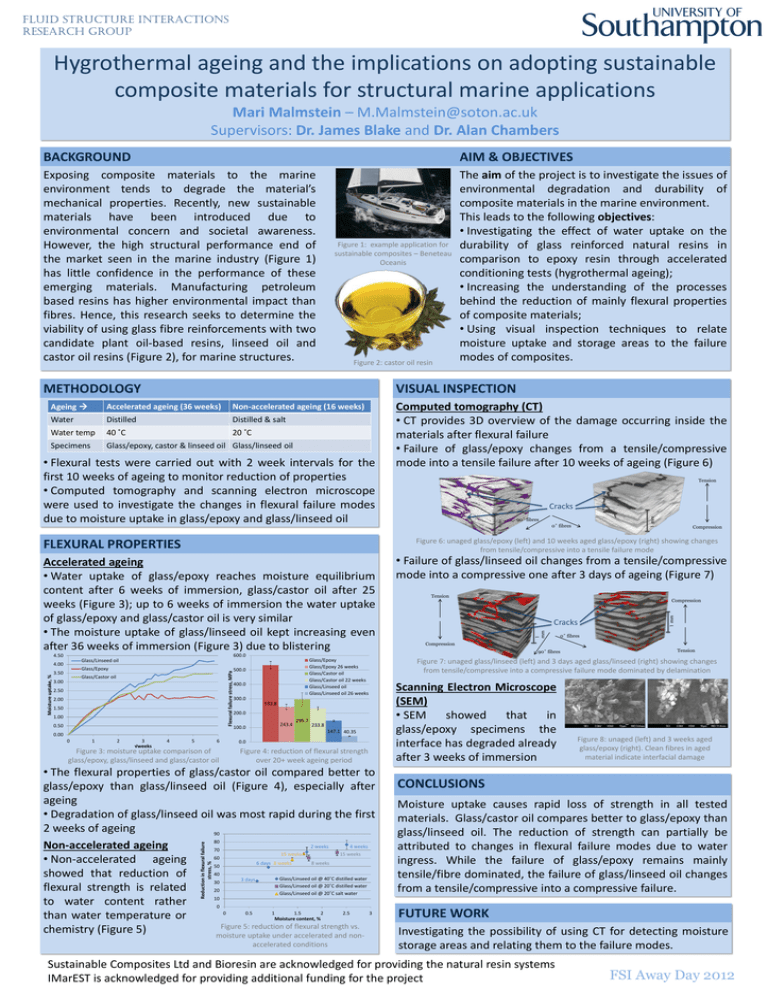

Fluid Structure Interactions Research Group Hygrothermal ageing and the implications on adopting sustainable composite materials for structural marine applications Mari Malmstein – M.Malmstein@soton.ac.uk Supervisors: Dr. James Blake and Dr. Alan Chambers BACKGROUND AIM & OBJECTIVES Exposing composite materials to the marine environment tends to degrade the material’s mechanical properties. Recently, new sustainable materials have been introduced due to environmental concern and societal awareness. However, the high structural performance end of the market seen in the marine industry (Figure 1) has little confidence in the performance of these emerging materials. Manufacturing petroleum based resins has higher environmental impact than fibres. Hence, this research seeks to determine the viability of using glass fibre reinforcements with two candidate plant oil-based resins, linseed oil and castor oil resins (Figure 2), for marine structures. The aim of the project is to investigate the issues of environmental degradation and durability of composite materials in the marine environment. This leads to the following objectives: • Investigating the effect of water uptake on the durability of glass reinforced natural resins in comparison to epoxy resin through accelerated conditioning tests (hygrothermal ageing); • Increasing the understanding of the processes behind the reduction of mainly flexural properties of composite materials; • Using visual inspection techniques to relate moisture uptake and storage areas to the failure modes of composites. Figure 1: example application for sustainable composites – Beneteau Oceanis Figure 2: castor oil resin VISUAL INSPECTION Accelerated ageing (36 weeks) Non-accelerated ageing (16 weeks) Water Distilled Distilled & salt Water temp 40 ˚C 20 ˚C Specimens Glass/epoxy, castor & linseed oil Glass/linseed oil • Flexural tests were carried out with 2 week intervals for the first 10 weeks of ageing to monitor reduction of properties • Computed tomography and scanning electron microscope were used to investigate the changes in flexural failure modes due to moisture uptake in glass/epoxy and glass/linseed oil 600.0 4.50 Glass/Epoxy Flexural failure stress, MPa Moisture uptake, % Glass/Epoxy Glass/Epoxy 26 weeks Glass/Castor oil Glass/Castor oil 22 weeks Glass/Linseed oil Glass/Linseed oil 26 weeks Glass/Linseed oil Glass/Castor oil 3.00 2.50 2.00 1.50 1.00 0.50 500.0 400.0 300.0 533.8 200.0 100.0 0.00 0 1 2 3 √weeks 4 Cracks 90˚ fibres 0˚ fibres Compression 5 6 Figure 3: moisture uptake comparison of glass/epoxy, glass/linseed and glass/castor oil 243.4 295.7 233.8 147.1 40.35 0.0 Figure 4: reduction of flexural strength over 20+ week ageing period Reduction in flexural failure stress, % • The flexural properties of glass/castor oil compared better to glass/epoxy than glass/linseed oil (Figure 4), especially after ageing • Degradation of glass/linseed oil was most rapid during the first 2 weeks of ageing 90 80 2 weeks 4 weeks Non-accelerated ageing 70 15 weeks 15 weeks 60 • Non-accelerated ageing 6 days 8 weeks 8 weeks 50 40 showed that reduction of Glass/Linseed oil @ 40˚C distilled water 3 days 30 Glass/Linseed oil @ 20˚C distilled water flexural strength is related 20 Glass/Linseed oil @ 20˚C salt water 10 to water content rather 0 0 0.5 1 1.5 2 2.5 3 than water temperature or Moisture content, % Figure 5: reduction of flexural strength vs. chemistry (Figure 5) moisture uptake under accelerated and nonaccelerated conditions • Failure of glass/linseed oil changes from a tensile/compressive mode into a compressive one after 3 days of ageing (Figure 7) Tension Cracks 1 mm Compression 1 mm Accelerated ageing • Water uptake of glass/epoxy reaches moisture equilibrium content after 6 weeks of immersion, glass/castor oil after 25 weeks (Figure 3); up to 6 weeks of immersion the water uptake of glass/epoxy and glass/castor oil is very similar • The moisture uptake of glass/linseed oil kept increasing even after 36 weeks of immersion (Figure 3) due to blistering 3.50 Tension Figure 6: unaged glass/epoxy (left) and 10 weeks aged glass/epoxy (right) showing changes from tensile/compressive into a tensile failure mode FLEXURAL PROPERTIES 4.00 Computed tomography (CT) • CT provides 3D overview of the damage occurring inside the materials after flexural failure • Failure of glass/epoxy changes from a tensile/compressive mode into a tensile failure after 10 weeks of ageing (Figure 6) 1 mm Ageing 1 mm METHODOLOGY 0˚ fibres Compression 90˚ fibres Tension Figure 7: unaged glass/linseed (left) and 3 days aged glass/linseed (right) showing changes from tensile/compressive into a compressive failure mode dominated by delamination Scanning Electron Microscope (SEM) • SEM showed that in glass/epoxy specimens the interface has degraded already after 3 weeks of immersion Figure 8: unaged (left) and 3 weeks aged glass/epoxy (right). Clean fibres in aged material indicate interfacial damage CONCLUSIONS Moisture uptake causes rapid loss of strength in all tested materials. Glass/castor oil compares better to glass/epoxy than glass/linseed oil. The reduction of strength can partially be attributed to changes in flexural failure modes due to water ingress. While the failure of glass/epoxy remains mainly tensile/fibre dominated, the failure of glass/linseed oil changes from a tensile/compressive into a compressive failure. FUTURE WORK Investigating the possibility of using CT for detecting moisture storage areas and relating them to the failure modes. Sustainable Composites Ltd and Bioresin are acknowledged for providing the natural resin systems IMarEST is acknowledged for providing additional funding for the project FSI Away Day 2012